Clamping and positioning mechanism for polishing bent edges of filter tank body

A technology of clamping and positioning and filtering tanks, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding the edge of workpieces. It can solve the problems of large manual labor and low efficiency, and achieve good results and firm clamping. , The effect of reducing the amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

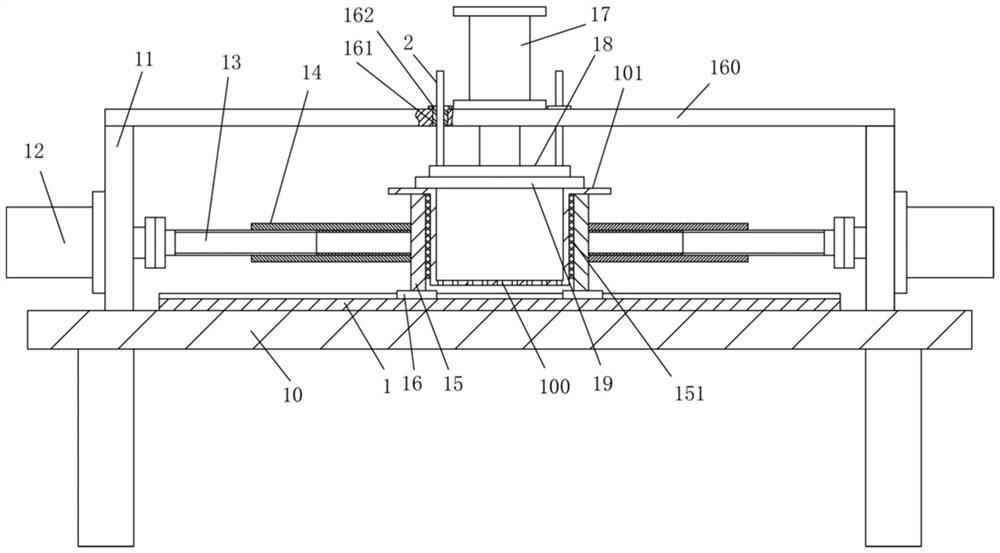

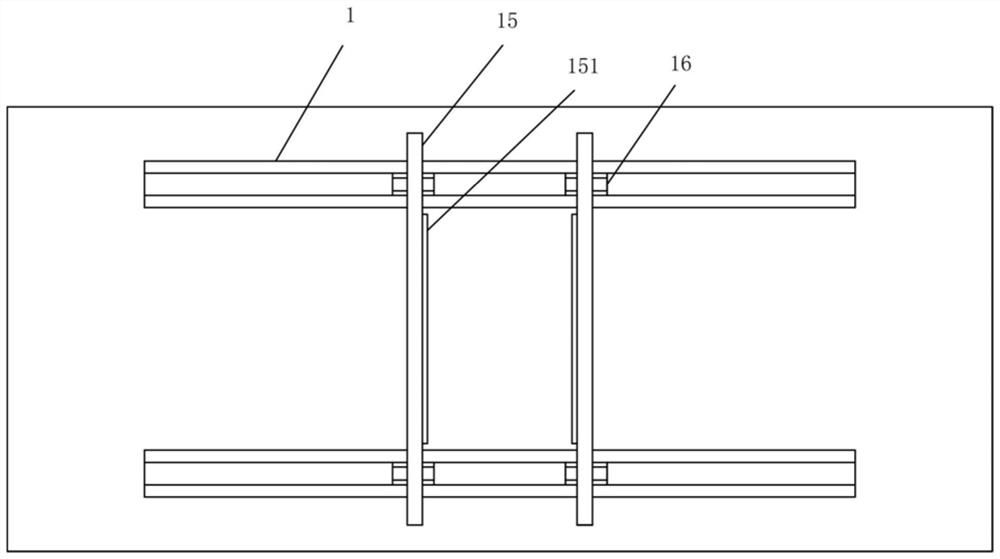

[0017] Examples, see e.g. Figure 1 to Figure 3 As shown in the figure, a clamping and positioning mechanism for grinding while bending the filter tank body includes a frame 10, and at least one guide rail 1 is fixed in the middle of the top surface of the top plate of the frame 10;

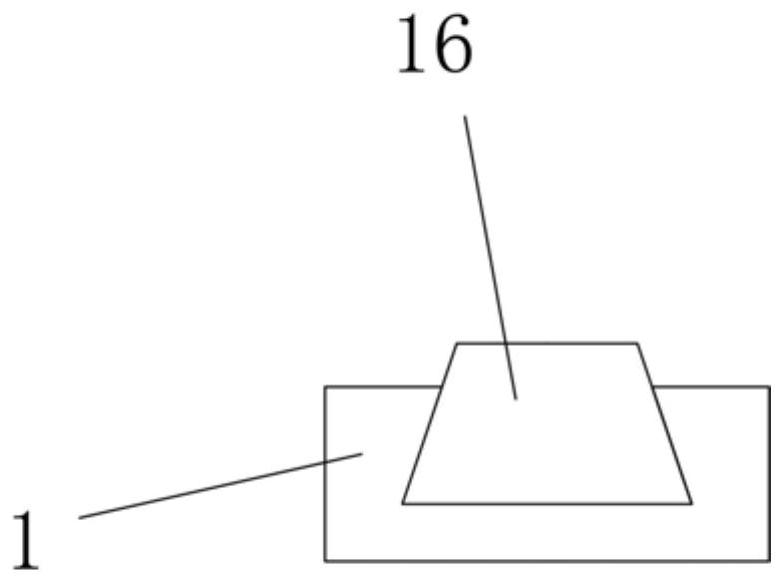

[0018] The left and right sides of the top plate of the frame 10 are fixed with vertical plates 11, the guide rail 1 is between the two vertical plates 11, and the output shaft of the mobile motor 12 is fixed on the outer wall of the vertical plate 11 to pass through. The vertical plate 11 is connected with a transverse screw rod 13 through a shaft coupling, and the transverse screw sleeve 14 is screwed on the horizontal screw rod 13. The end of the horizontal screw sleeve 14 is fixed with a compression plate 15, and the bottom surface of the compression plate 15 is fixed with a slide plate. block 16, the slider 16 is inserted in the chute of the guide rail 1, the filter tank body 100 to be proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com