Rotary type quick clamping device of pipeline grinding robot

A robotic and rotary technology, used in grinding drives, machine tools designed for grinding the rotating surface of workpieces, grinding frames, etc., can solve problems such as uneven grinding, poor safety, and affecting grinding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

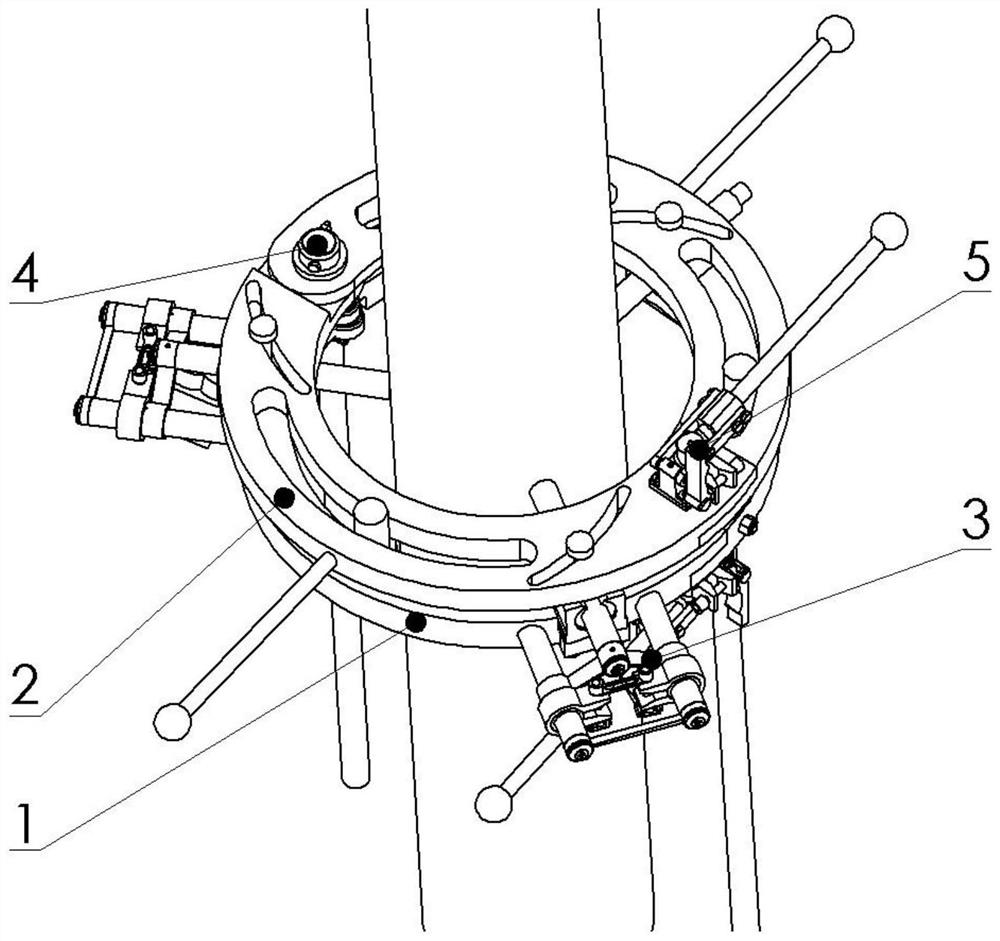

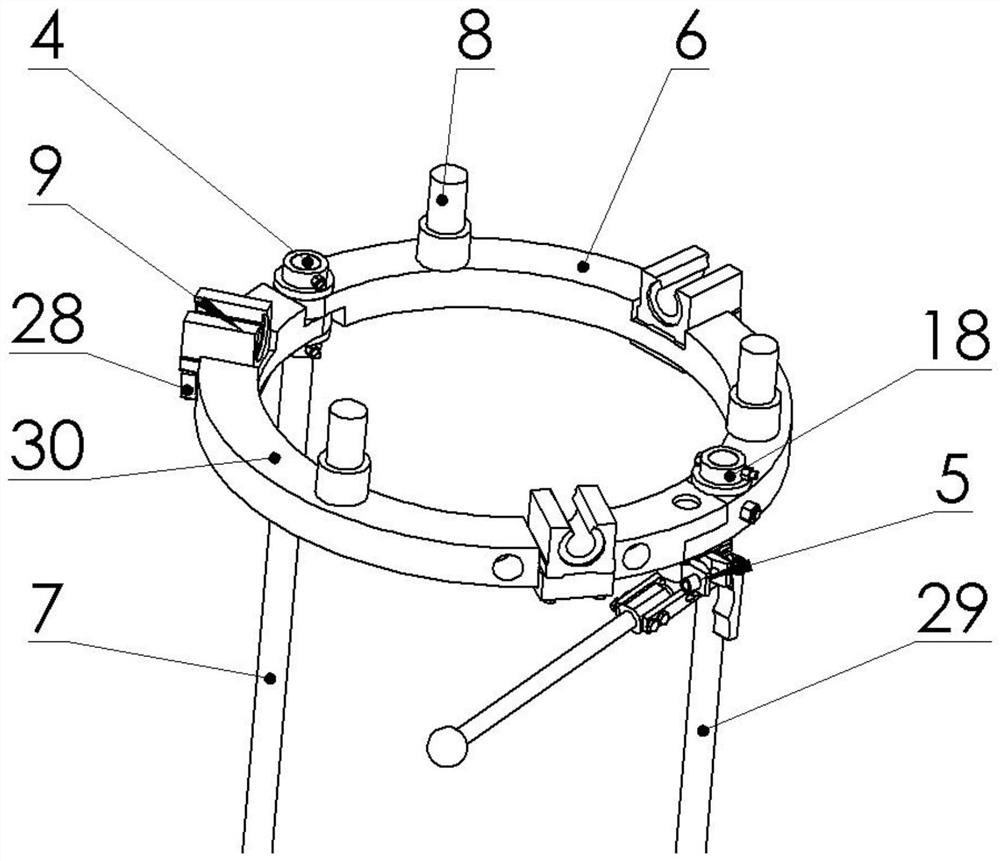

[0029] Combine below figure 1 The present invention will be explained.

[0030] Such as figure 1 As shown, the present invention is mainly composed of frame part 1, rotary feed part 2, brake mechanism 3, coaxial rotary joint 4, and plug-in pin mechanism 5. There are two coaxial rotary joints 4 in frame part 1 and One type is installed on the rotary feeding part 2 to ensure that the frame part 1 and the rotary feeding part 2 can respectively realize their own opening and closing movements. When the axes of the two coaxial rotary joints 4 coincide, the whole device can be divided into two parts, and each part can rotate freely around the coaxial rotary joint 4, so that the whole device can be quickly installed and disassembled on the non-detachable pipeline at the construction site; The pin pulling mechanism 5 is also installed on the frame part 1 and the rotary feeding part 2 respectively to ensure that the frame part 1 and the rotary feeding part 2 can respectively realize their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com