A heavy-duty automobile axle head forging parts manufacturing equipment

A technology for heavy-duty vehicles and manufacturing equipment, applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc., can solve complex, inconvenient cutting or drilling, environmental pollution and other problems, and achieve easy operation, easy processing, and easy cutting or drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

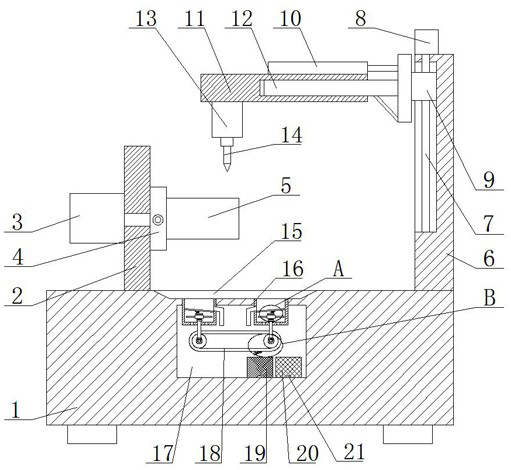

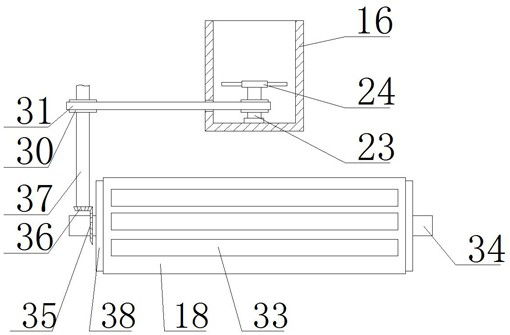

[0030] refer to Figure 1-6 , a kind of heavy-duty automobile axle head forging parts manufacturing equipment, comprising a body 1, a rotating structure is arranged on the top of the body 1, a workpiece 5 is connected to the rotating structure, a vertical plate 6 is fixedly connected to the top of the body 1, and a vertical plate 6 is arranged on the vertical plate 6 Lifting structure, the lifting structure is connected with a transverse bar 11, the bottom of the transverse bar 11 is connected with a cutting motor 13, the cutting motor 13 is connected with a cutting head 14, the top of the body 1 is provided with a dust guide groove 15 and a cavity 17, the cavity 17 and the dust guide groove 15 are connected with two dust suction tubes 16, and the dust-retaining structure is arranged in the two dust suction tubes 16, and the suction structure is installed in the rotation of the two dust suction tubes 16, and the cavity 17 A transmission structure is provided, and the transmiss...

Embodiment 2

[0041] refer to Figure 1-6 , a heavy-duty automobile shaft head forging parts manufacturing equipment, including a body 1, the top of the body 1 is provided with a rotating structure, a workpiece 5 is connected to the rotating structure, the top of the body 1 is fixedly connected with a vertical plate 6 by screws, and the vertical plate 6 is A lifting structure is provided, and a horizontal rod 11 is connected to the lifting structure, a cutting motor 13 is connected to the bottom of the horizontal rod 11, a cutting head 14 is connected to the cutting motor 13, and a dust guide groove 15 and a cavity 17 are arranged on the top of the body 1. Two dust suction tubes 16 are connected between the cavity 17 and the dust guide groove 15. The two dust suction tubes 16 are all provided with a dust-proof structure, and the two dust suction tubes 16 are all rotatably installed with an air suction structure. 17 is provided with a transmission structure, the transmission structure is ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com