Device and method for removing mud from rigid joints of underground diaphragm walls

An underground continuous wall and removal device technology, which is applied to cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc. The effect of improving project cost and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

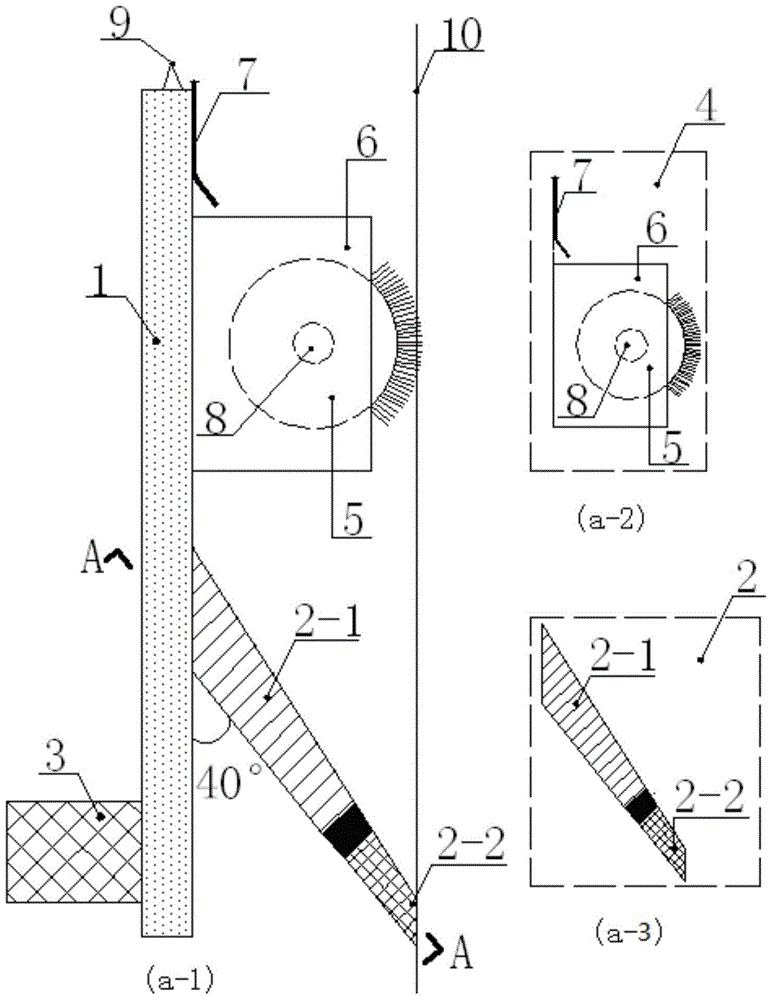

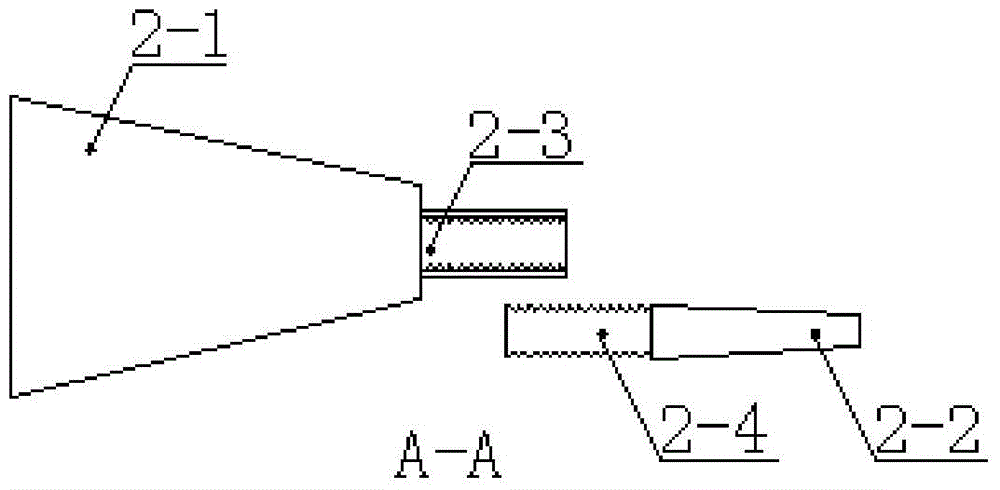

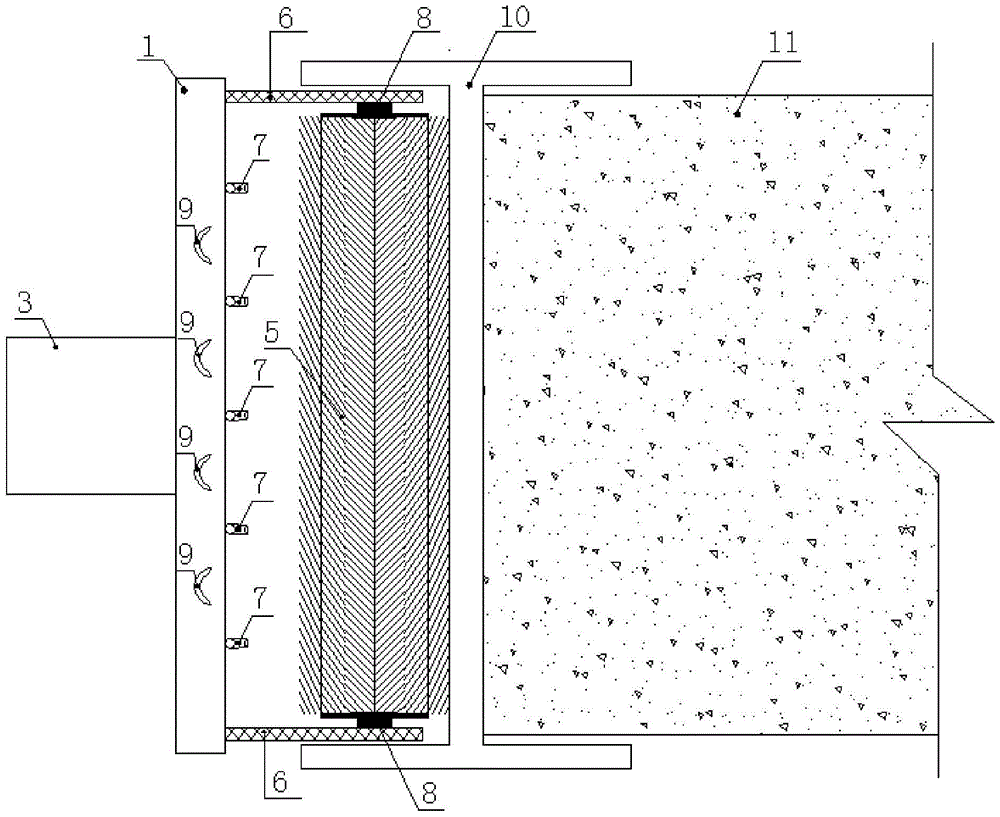

[0045] As shown in Figure 1(a) and Figure 1(b), this embodiment provides a mud removal device at the rigid joint of the underground diaphragm wall, the removal device includes: a fixed module 1, a mud removal module 2, a balance module 3, The water washing and rolling mud cleaning module 4, the suspension ring 9, and the connection relationship between each part are as follows:

[0046] The lifting rings 9 are evenly distributed on the top of the fixed module 1; the desilting module 2 is located on one side of the fixed module 1, and the position of the desilting module 2 is close to the bottom of the fixed module 1, and the desilting module 2 is fixedly connected with the fixed module 1; The mud module 4 and the mud removal module 2 are located on the same side, and the water washing and rolling mud cleaning module 4 is located close to the top of the fixed module 1. The water washing and rolling mud cleaning module 4 is connected to the fixed module 1 by welding through its o...

Embodiment 2

[0053] In this embodiment, a certain subway line is taken as an example. The design unit of the main enclosure structure adopts an underground diaphragm wall with a thickness of 1200mm and 5 vertical internal supports. The web height of 10 is 1000mm, and the depth of underground diaphragm wall 11 is 27m. The soil layer from top to bottom of the foundation groove side wall of underground diaphragm wall 11 can be divided into three types: the first type of soil layer is coarse sand layer and medium sand layer. layer, with a thickness of 3.0m and 4.2m; the second type of soil layer is clay, silty clay, and sandy clay layer, with a thickness of 3.0m, 4.2m, and 4.1m; the third type of soil layer is silty The clay and muddy soil are 4.4m and 4.1m thick respectively.

[0054] This embodiment provides a method for removing mud at the rigid joint of an underground diaphragm wall, the method is based on the removal device, and the specific implementation is as follows:

[0055] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com