A Flexible Fixture with Adaptive Support and Multi-point Compression

A flexible fixture and self-adaptive technology, applied in the field of tooling and fixtures, can solve problems that affect product quality and processing efficiency, difficult processing, and large volume of assembled fixtures, so as to improve processing quality and production efficiency, and ensure processing accuracy and surface quality. Quality, shortening the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

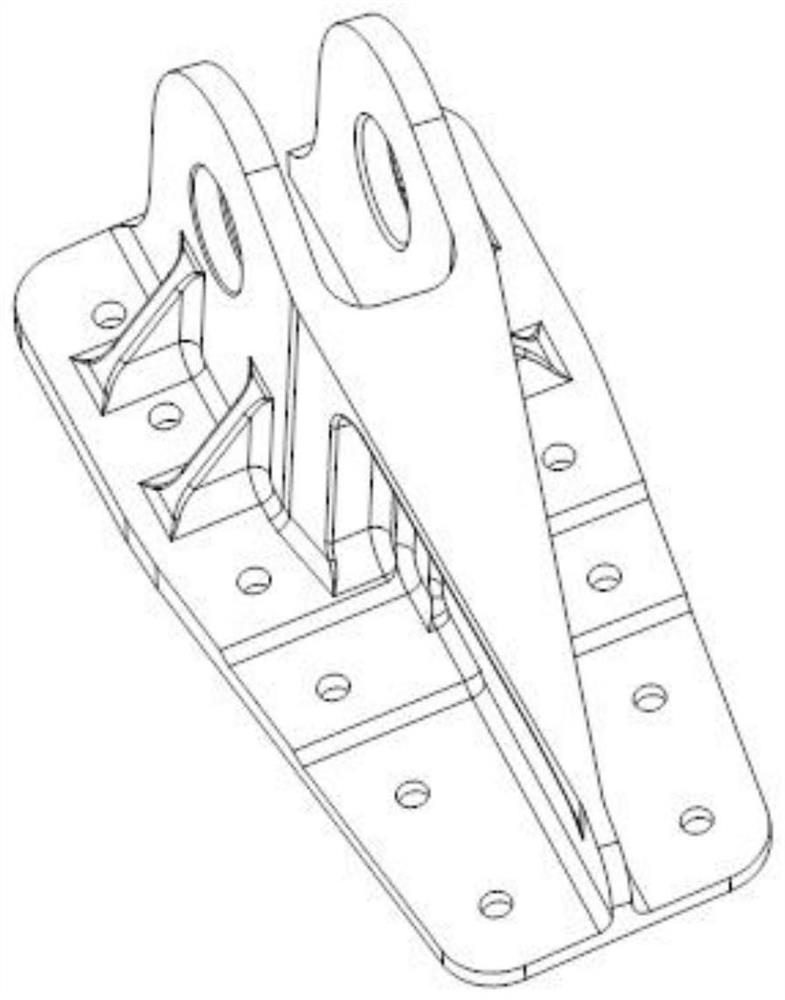

[0046] A flexible fixture with adaptive support and multi-point compression, such as Figure 1-Figure 5 , Figure 7 , Figure 8 As shown, it includes a clamp base 1 and a first adaptive clamping device 2, a second adaptive clamping device 3, an adaptive support device 4, and clamp support bosses 1-10 arranged on the clamp base 1; An adaptive clamping device 2 and a second adaptive clamping device 3 are respectively slidably connected to the fixture base 1, and the two ends of the first adaptive clamping device 2 and the second adaptive clamping device 3 are respectively connected to the part A The surface 8-2 and the part B surface 8-3 are compressed; the self-adaptive support device 4 is attached to the part C surface 8-4; the opening slot of the part is inserted into the fixture support boss 1-10, and the part main positioning sleeve 5 Insert the part positioning hole 8-1, the clamp support boss 1-10 and connect with the compression bolt 7.

[0047] In the present inventio...

Embodiment 2

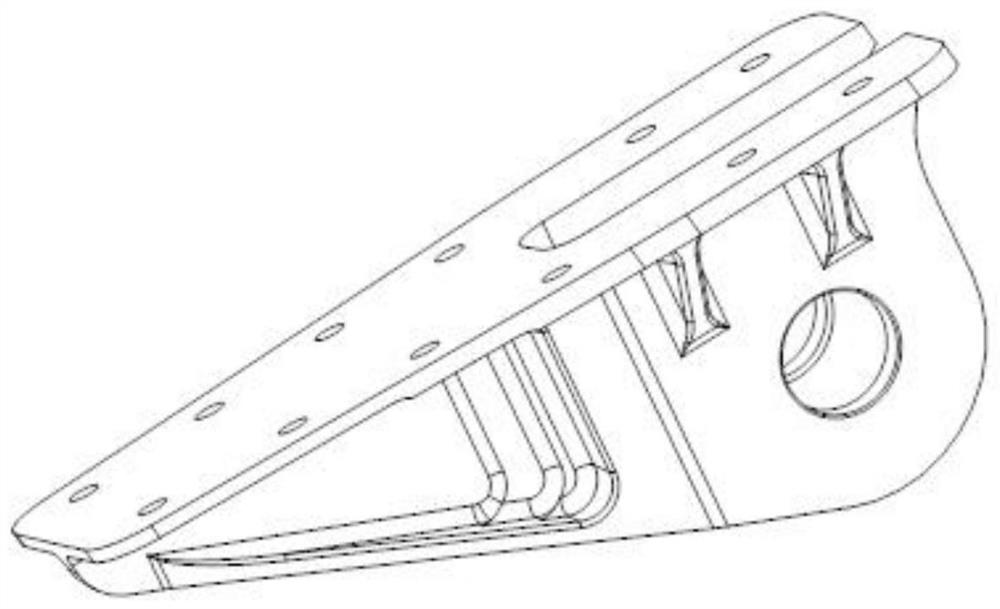

[0050] This embodiment is optimized on the basis of embodiment 1, such as Image 6 , Figure 8-Figure 11 As shown, the fixture base 1 is positioned in the T-shaped slot of the machine tool workbench through the convex key, and is installed and fixed on the machine tool workbench through the T-shaped keys 1-4 and the fixing bolts 1-5. The two ends of the bottom of the fixture base 1 are respectively provided with rectangular convex keys 1-3, and the middle part is provided with diamond-shaped convex keys 1-6.

[0051] Other parts of this embodiment are the same as those of Embodiment 1, so details are not repeated here.

Embodiment 3

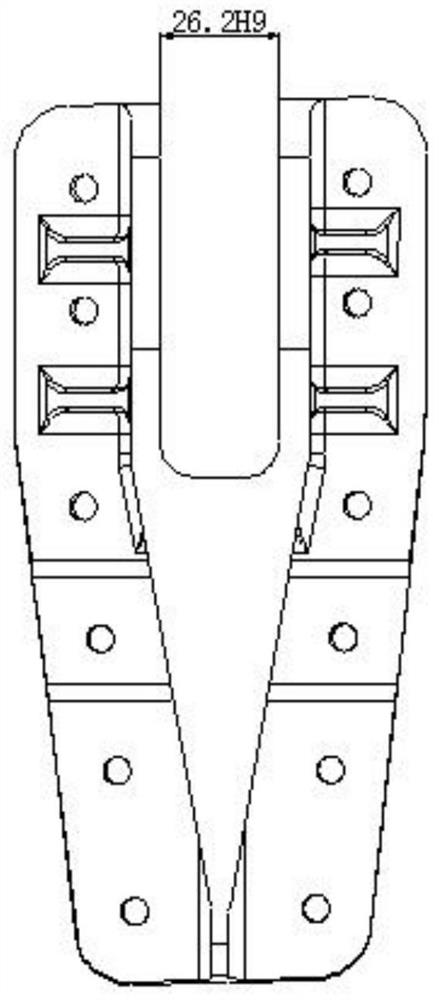

[0053] This embodiment is optimized on the basis of embodiment 1 or 2, as Figure 12-Figure 15 As shown, the first self-adaptive clamping device 2 includes a pressing seat slidably arranged on the clamp base 1 . The upper surface of the clamp base 1 is provided with a first T-shaped groove 1-1 corresponding to the first self-adaptive clamping device 2, and a first step boss 2-1 is correspondingly provided on the pressing seat, and the first The stepped boss 2-1 is slidingly connected with the first T-shaped slot 1-1. Left and right stud bolts 2-4 are arranged between adjacent compression seats, and adaptive support devices 4 are respectively provided on opposite sides of adjacent compression seats; Thread 4-2, hole 2-5, self-adaptive device pressing countersunk hole 2-6, left and right stud bolt connection threaded hole 2-7.

[0054] Other parts of this embodiment are the same as those of Embodiment 1 or 2 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com