Perceptual execution actuator material with self-cleaning function as well as preparation method and application of perceptual execution actuator material

A self-cleaning, actuator technology, applied in the field of materials, can solve the problems of lack of perceptual feedback adjustment, difficult to maintain consistency of surface capacitive reactance and electric performance, inability to perceive and feedback control, etc., and achieve long-term stable friction performance. The effect of changing, the action effect is stable for a long time, and the effect of avoiding performance and accuracy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Fabrication of sensory-actuator materials with self-cleaning capabilities

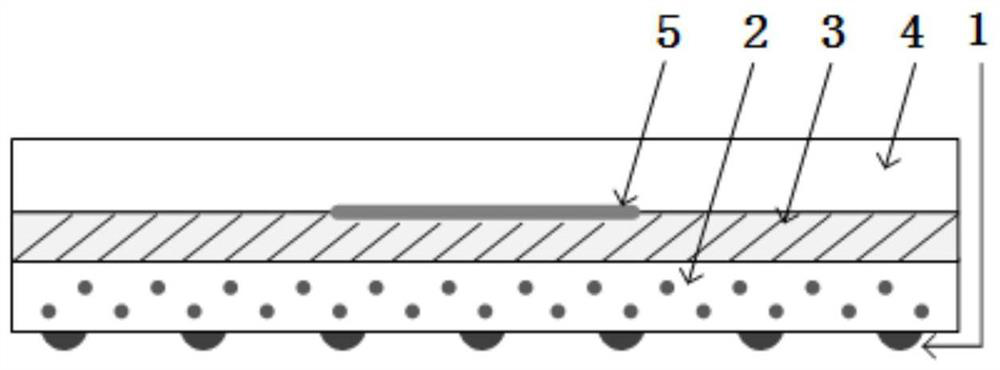

[0047] The schematic diagram of the material structure is shown in figure 1 As shown, from bottom to top, the self-cleaning functional layer 1, the bionic actuating layer 2, the sensing layer 3 and the insulating protective layer 4 are stacked in order. figure 2 As shown, the preparation method is as follows:

[0048] 1) Preparation of semi-solidified intermediate state bionic actuating layer: adding NdFeB with a particle size of 30 μm to polydimethylsiloxane, first mechanically stirring at a speed of 80 r / min for 20 min, then ultrasonically oscillating for 15 min, and then vacuuming 20min defoaming, then adding hexamethyldiisocyanate, mechanically stirring again at a speed of 80r / min for 20min, then ultrasonically oscillating for 15min, then vacuuming for 20min to defoaming, and finally heating at 60°C for 45min, at 10min intervals at 25r / min Mechanical stirring at a speed of min for 2 min to...

Embodiment 2

[0057] Fabrication of sensory-actuator materials with self-cleaning capabilities

[0058] The schematic diagram of the material structure is shown in figure 1 As shown, from bottom to top, the self-cleaning functional layer 1, the bionic actuating layer 2, the sensing layer 3 and the insulating protective layer 4 are stacked in order. figure 2 As shown, the preparation method is as follows:

[0059] 1) Preparation of semi-solidified intermediate state bionic actuating layer: add NdFeB with a particle size of 30 μm to the polyurethane, first mechanically stir at a speed of 100 r / min for 10 min, then ultrasonically vibrate for 30 min, then vacuumize for 15 min to remove foam, and then add Isophorone diisocyanate was mechanically stirred again at a speed of 100r / min for 10min, then ultrasonically vibrated for 30min, then vacuumed for 15min to remove foam, and finally heated at 60°C for 60min, with mechanical stirring at a speed of 20r / min at 5min intervals For 3 min, a semi-so...

Embodiment 3

[0066] Fabrication of sensory-actuator materials with self-cleaning capabilities

[0067] The schematic diagram of the material structure is shown in figure 1 As shown, from bottom to top, the self-cleaning functional layer 1, the bionic actuating layer 2, the sensing layer 3 and the insulating protective layer 4 are stacked in order. figure 2 As shown, the preparation method is as follows:

[0068] 1) Preparation of semi-solidified intermediate state bionic actuating layer: adding NdFeB with a particle size of 48 μm to polydimethylsiloxane, first mechanically stirring at a speed of 50 r / min for 15 min, then ultrasonically oscillating for 10 min, and then vacuuming 10min defoaming, then adding dimethyl biphenyl diisocyanate, mechanical stirring for 15min at a speed of 50r / min, ultrasonic vibration for 10min, vacuuming for 10min to defoaming, and finally heating at 65°C for 30min, with 8min intervals Mechanical stirring at a speed of 50 r / min for 2 min to obtain a semi-solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com