Tripping mechanism of residual current circuit breaker

A leakage circuit breaker and tripping mechanism technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of transmission delay, complex tripping structure, high cost of tripping mechanism, etc., and achieve small tripping force and eliminate circuit breakers. Failure and safety hazards, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

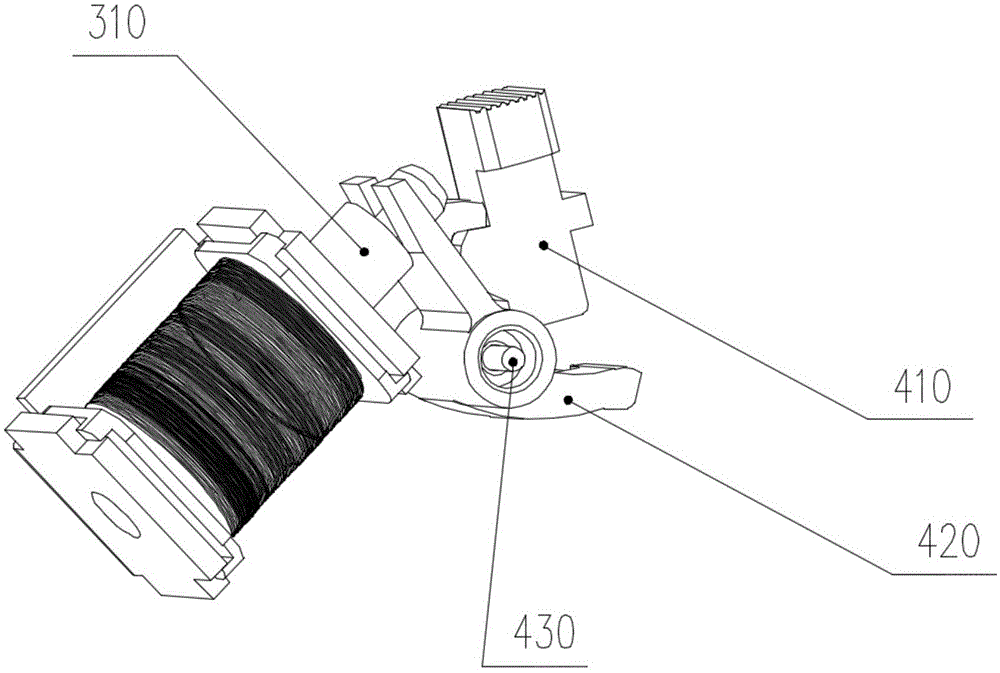

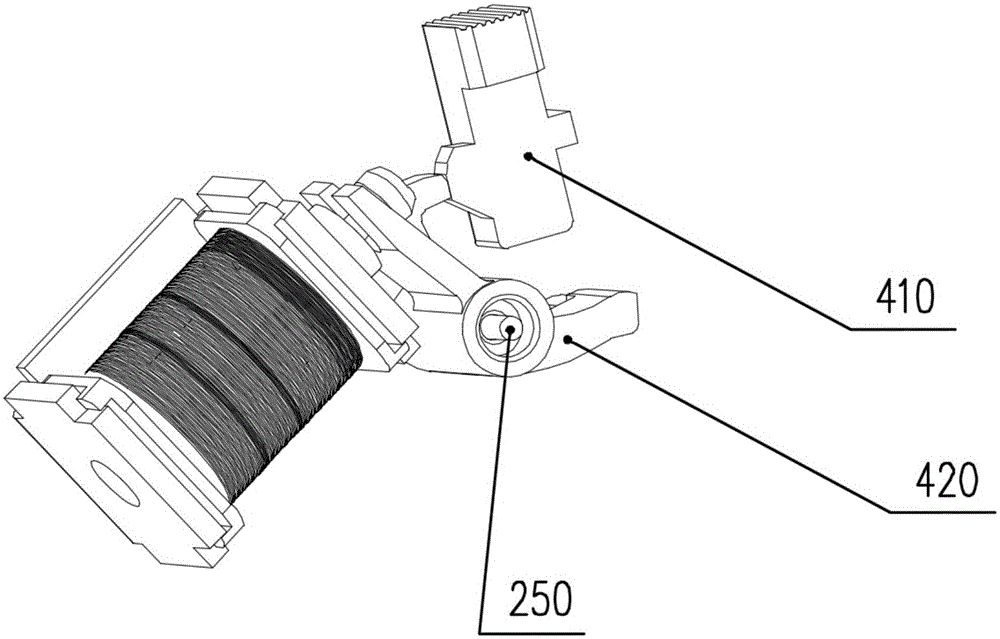

[0015] Such as Figure 1-Figure 5 The tripping mechanism of a leakage circuit breaker shown includes a circuit breaker housing 5, a circuit breaking mechanism, a leakage current detection system 1, an electronic control system 2, an electromagnetic tripper 3 and a trip reset device 4, the tripping The reset device includes a reset member 410, a trip link 420, an installation shaft 250, and a return spring. The reset member 410 is slidably engaged with the circuit breaker housing 5 through the return spring, and the middle part of the trip link 420 is connected by rotation through the installation shaft 250. Below the reset member 410 , the moving iron core 310 of the electromagnetic release 3 is in transmission connection with one end of the trip link 420 , and one end of the trip link 420 is also provided with a hook that buckles or abuts against the reset member 410 430, the other end of the tripping link 420 (and the linkage bar 4240) is in transmission connection with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com