Quartz sand pickling purification processing technology

A processing technology, quartz sand technology, applied in water/sludge/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problem of low heating efficiency, reduce energy consumption, save feeding time, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

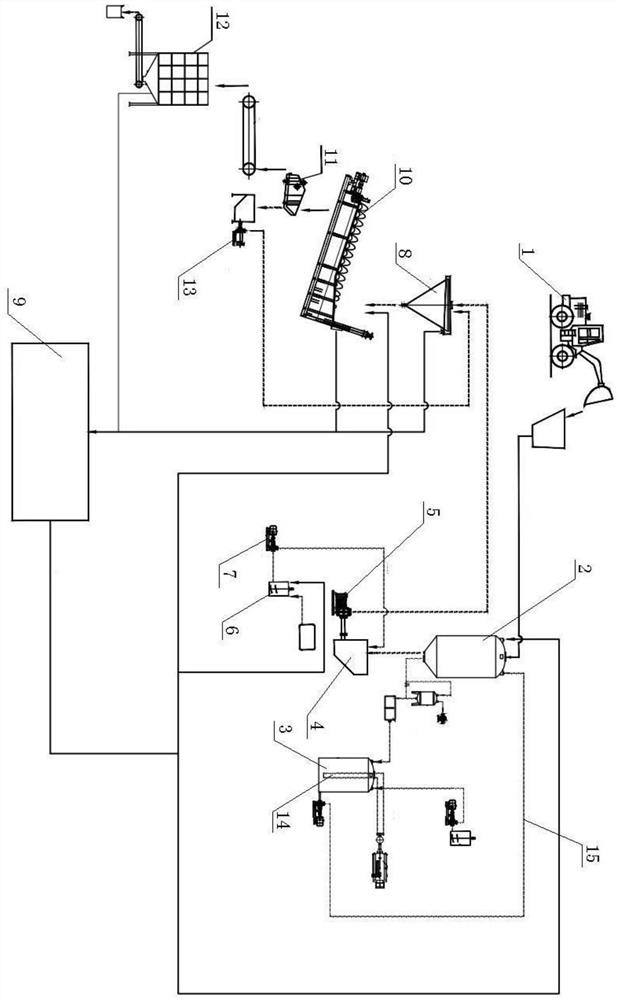

Image

Examples

Embodiment 1

[0030] The quartz sand pickling and purification process of the present invention is used to produce 15ppm high-purity quartz sand in Hubei Damei Silicon Industry Technology Co., Ltd., and the specific steps include:

[0031] Use the loader 1 to add 60ppm of quartz sand raw material into the pickling tank 2 through the belt conveyor (the process takes 45min), and then add the 60ppm quartz sand raw material to the pickling tank 2 and preheat it to 75°C in advance through the steam coil 14. The concentration is 0.5 Mixed hot acid 15 of % hydrofluoric acid + 6% oxalic acid (hydrofluoric acid: oxalic acid = 1:10 (v / v), the acid addition process takes 30 minutes), pickling in pickling tank 2 for 18 hours and then discharging the acid After 3 hours of recovery, the recovery rate is about 92%;

[0032] The recovered acid is discharged to the acid liquid circulation tank 3 through a vacuum pump for use; then, clean water is added to the pickling tank 2 to discharge the quartz sand thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com