Efficient heat dissipation system for pole coil of hydro-generator

A hydro-generator and heat dissipation system technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of poor heat dissipation effect of magnetic poles, uneven temperature, complex structure of heat dissipation system, etc., to reduce ventilation loss and ensure uniformity Heat dissipation, avoid the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

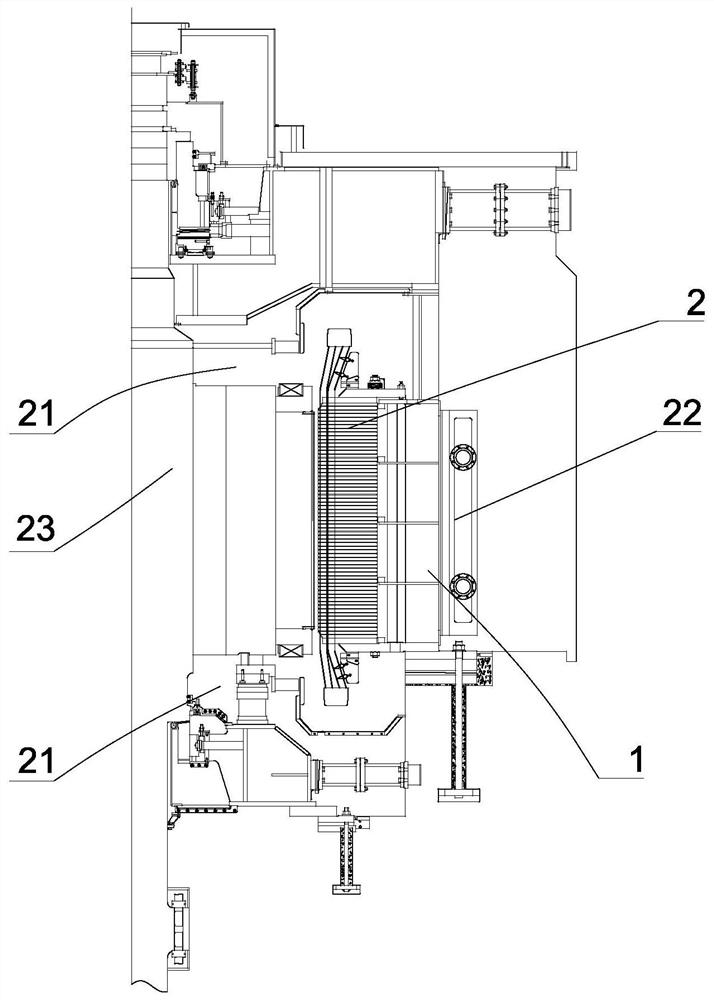

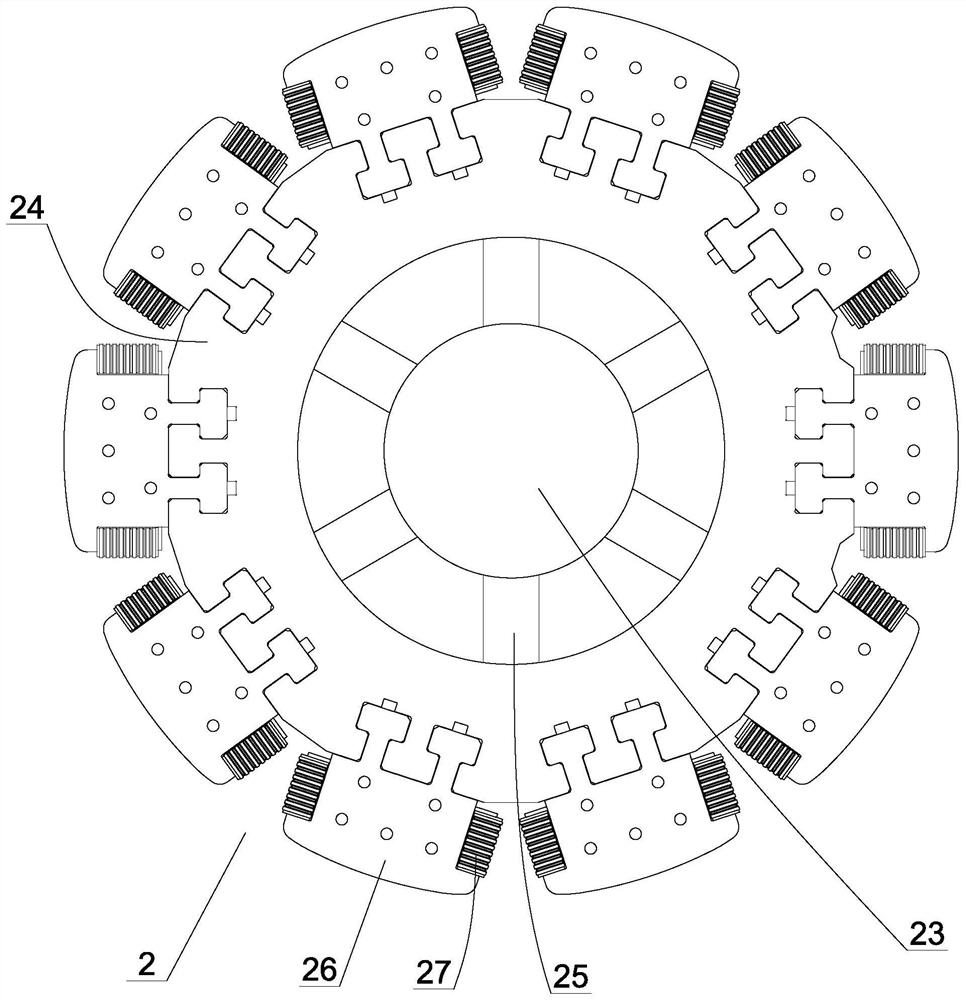

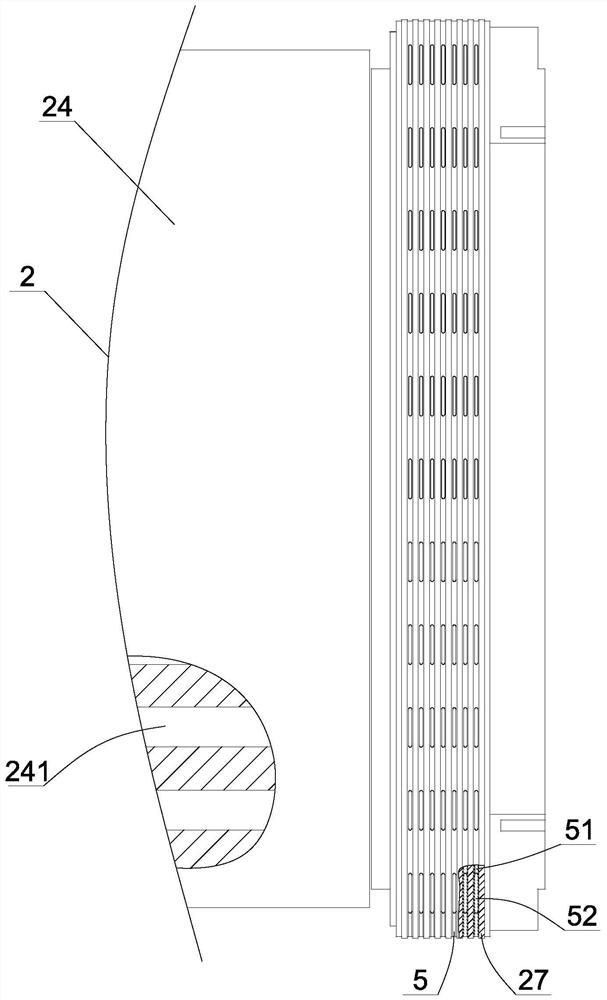

[0038] Such as figure 1 As shown, a high-efficiency heat dissipation system for the magnetic pole coil of a hydro-generator includes a stator 1, a rotor 2 rotatably arranged in the stator, and a cooling and heat dissipation system (not shown in the figure) for cooling and driving the cooling air, such as figure 2 As shown, the rotor includes a middle shaft 23, a peripheral yoke 24, a bracket 25 for connecting the shaft and the yoke, a number of magnetic poles arranged around the yoke, the magnetic poles include an iron core 26, and a Several layers of rectangular frame-shaped copper bars 27. In order to facilitate the heat dissipation and cooling of the rotor and stator, such as image 3 As shown, we need to respectively set several radial ventilation holes 241 arranged at intervals along the axial direction on the yoke, the iron core and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com