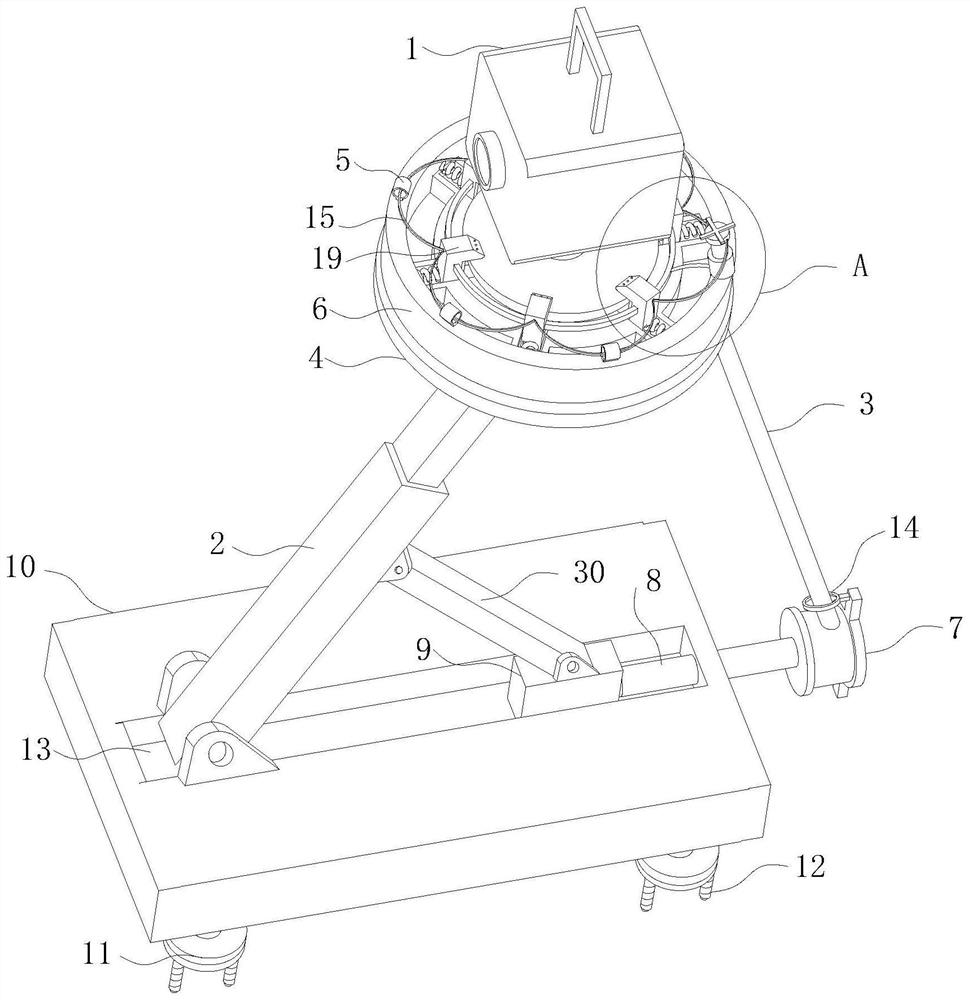

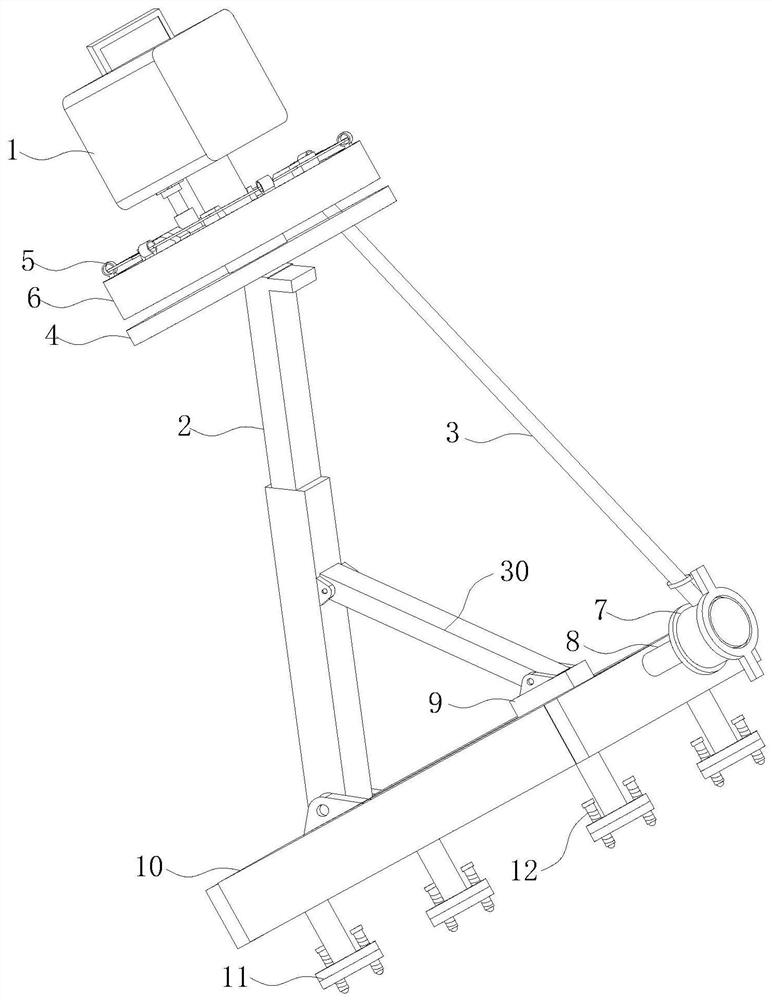

Three-dimensional optical scanner

A technology of three-dimensional optics and scanners, applied in the field of three-dimensional scanners, can solve problems such as difficult handling, inconvenient height adjustment of scanners, vibration damage, etc., and achieve the effect of firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

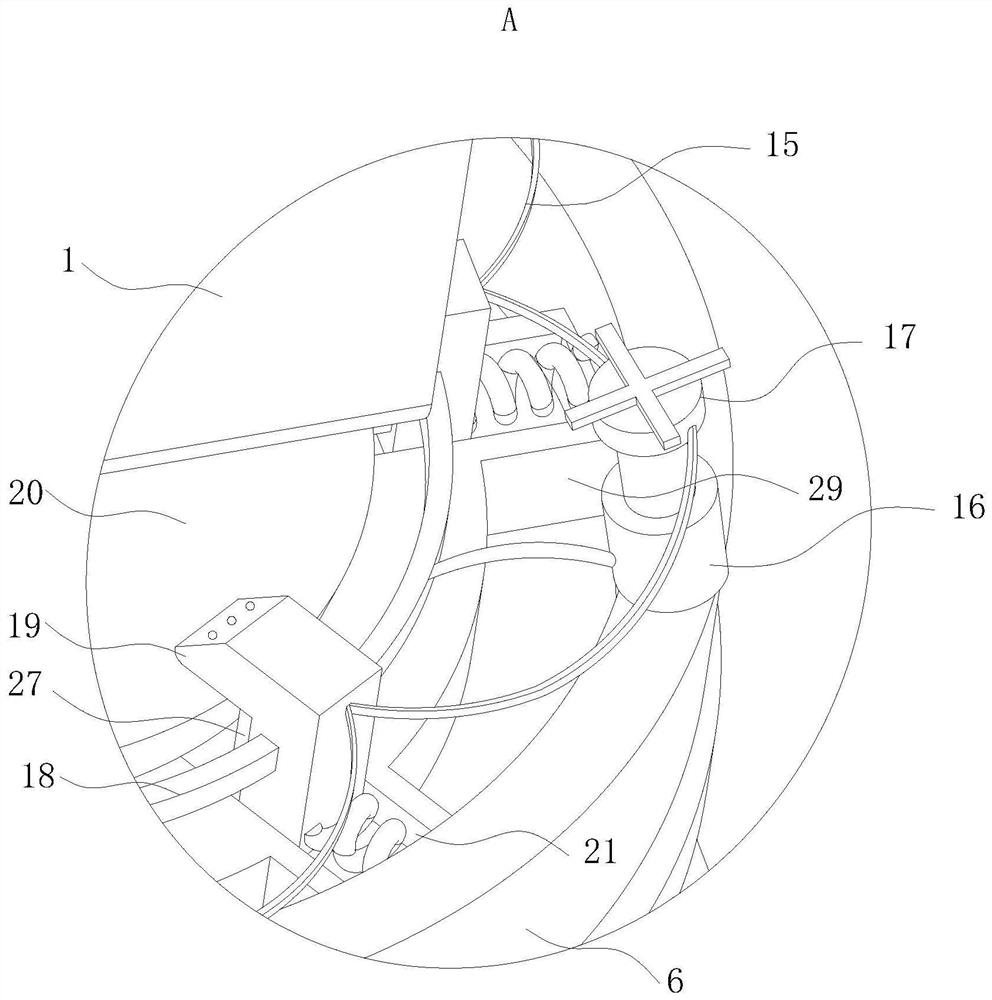

[0030] As an embodiment of the present invention, a first columnar airbag 31 is arranged in the columnar cavity inside the fixed ring 6, and an extrusion plate is fixedly arranged on the top of the first columnar airbag 31; the clamping rod 19 is vertically Clamping airbags 27 are fixed in the groove of the inner wall of the rod; the clamping airbags 27 communicate with each other through the annular air pipe 18, and the annular air pipe 18 communicates with the first columnar air bag 31 through a connecting pipe; during work, when required When installing the scanner body 1 again, put the installation disc 20 between several groups of clamping rods 19, then screw the vertical screw 17 inwardly of the threaded column 16, and now the vertical screw 17 squeezes The first columnar airbag 31 located in the columnar cavity, the gas inside the first columnar airbag 31 enters the inside of the annular air pipe 18 through the connecting pipe, and then inflates the clamping airbag 27, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com