Fabricated pier and construction process thereof

A construction technology and prefabricated technology, applied in the field of prefabricated bridge piers and their construction technology, can solve the problems of immature construction technology of fully prefabricated bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

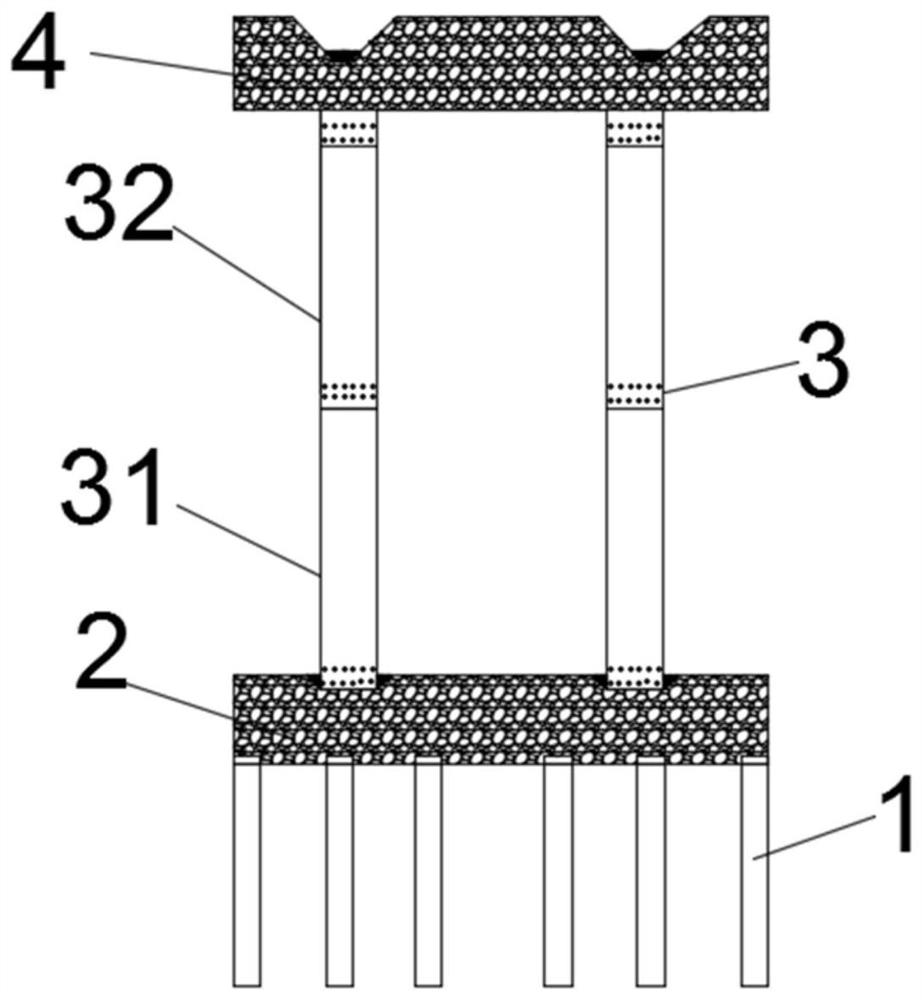

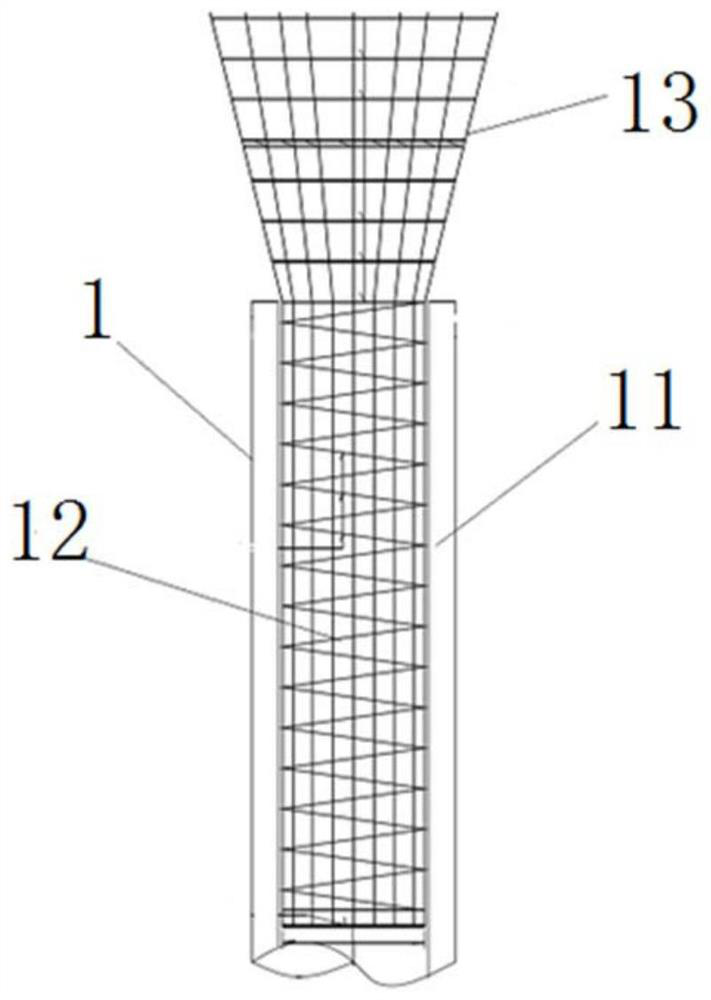

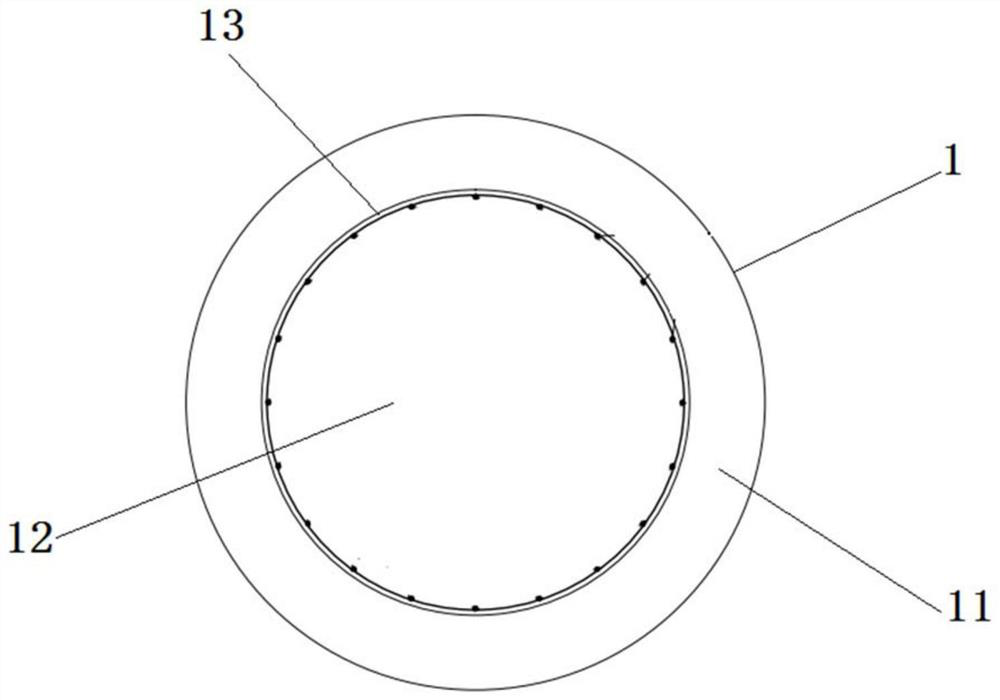

[0079] Refer to attached Figure 1-16The one shown includes a plurality of pipe piles 1, caps 2, pier columns 3 and cover beams 4. The pipe piles 1 are arranged at the lower end of the caps 2 and connected with the caps 2. The pier columns 3 include pier column segments with the same structure One 31 and pier column section two 32, the lower end of pier column section one 31 is installed on the upper end surface of cap 2, the upper end of pier column section one 31 is connected with the lower end of pier column section two 32, and the pier column section two The upper end of section two 32 is connected with tenon column 41 arranged at the lower end of cover beam 4; the cap 2 is connected with pier column section one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com