Preparation method of mildew-proof glass spacing paper

A glass spacer paper and anti-mildew technology, applied in the field of papermaking, can solve the problems of poor anti-mildew effect, etc., and achieve the effects of reducing the growth of mildew, strong hydrophobic effect, and improving the surface roughness of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

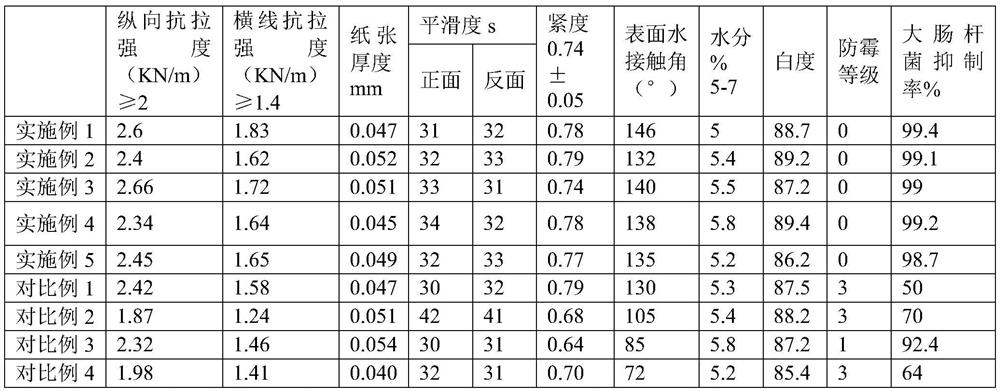

Examples

Embodiment 1

[0037] A preparation method for mildew-proof glass spacer paper, comprising the following steps:

[0038] (1) Preparation of base paper: after 55% bleached softwood pulp and 45% bleached hardwood pulp are chemically soaked for 3 hours, beating to 60 ° SR; get 58 parts by weight of bleached chemical pulp, 8 parts by weight of filler and 8 parts by weight After the cationic starch is mixed, it is filtered with clean water, dehydrated on the wire part, impregnated in the anti-mildew penetrating network polymer, pressed at 550kPa for 40min, and dried to obtain base paper;

[0039] The clear water filtration is to adopt circulating clear water to filter, and use a 5000 mesh precision cloth bag filter to filter;

[0040] The anti-mold penetrating network polymer is chitosan-polyvinyl alcohol-hexamethacrylate anti-mold polymer, and its preparation steps include: dissolving chitosan cellulose in 12% acetic acid solution by mass fraction, adding Add the antifungal agent sodium benzoat...

Embodiment 2

[0047] The difference from Example 1 is that a method for preparing an anti-mildew glass spacer paper comprises the following steps:

[0048] (1) Preparation of base paper: After soaking 50% bleached softwood pulp and 50% bleached hardwood pulp chemically for 3 hours, beat to 60 ° SR; get 50 parts by weight of bleached chemical pulp, 10 parts by weight of filler and 5 parts by weight After the cationic starch is mixed, it is filtered with clean water, dehydrated on the wire part, impregnated in the anti-mildew penetrating network polymer, pressed at 550kPa for 40min, and dried to obtain base paper;

[0049] The clear water filtration is to adopt circulating clear water to filter, and use a 5000 mesh precision cloth bag filter to filter;

[0050] The anti-mold penetrating network polymer is chitosan-polyvinyl alcohol-hexamethacrylate anti-mold polymer, and its preparation steps include: dissolving chitosan cellulose in 12% acetic acid solution by mass fraction, adding Add anti...

Embodiment 3

[0057] The difference from Example 1 is that a method for preparing an anti-mildew glass spacer paper comprises the following steps:

[0058] (1) Preparation of base paper: after 52% bleached softwood pulp and 48% bleached hardwood pulp are chemically soaked for 3 hours, beating to 60 ° SR; get 51 parts by weight of bleached chemical pulp, 9 parts by weight of filler and 6 parts by weight After the cationic starch is mixed, it is filtered with clean water, dehydrated on the wire part, impregnated in the anti-mildew penetrating network polymer, pressed at 550kPa for 40min, and dried to obtain base paper;

[0059] The clear water filtration is to adopt circulating clear water to filter, and use a 5000 mesh precision cloth bag filter to filter;

[0060] The anti-mold penetrating network polymer is chitosan-polyvinyl alcohol-hexamethacrylate anti-mold polymer, and its preparation steps include: dissolving chitosan cellulose in 12% acetic acid solution by mass fraction, adding Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com