Irradiation floor cloth and preparation method thereof

A floor and irradiation technology, applied in the field of irradiated floor cloth and its preparation, can solve the problems of plastic floor wear resistance and flame retardant performance not meeting the requirements, potential safety hazards, poor anti-skid performance, etc., to ensure the quality of production and use , optimize performance, eliminate the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

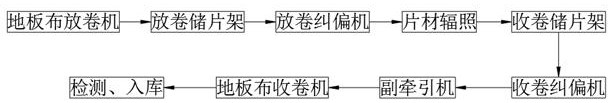

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] A kind of irradiation floor cloth, described floor cloth comprises the raw material of following weight ratio, PVC100 weight parts, dioctyl phthalate 50 weight parts, dioctyl sebacate 12 weight parts, stabilizer 4 weight parts, 6 parts by weight of lubricant, 40 parts by weight of magnesium hydroxide, 80 parts by weight of aluminum hydroxide, 2 parts by weight of titanate coupling agent, and 10 parts by weight of zinc borate.

[0037] A preparation method of irradiated floor cloth is as follows:

[0038] (1) Packing treatment

[0039] Put all the aluminum hydroxide and magnesium hydroxide in parts by weight into a high-speed processing machine, add the mixture of titanate coupling agent and lubricant dropwise when the temperature is 40°C-50°C, at 70°C±5°C Material cooling standby;

[0040] (2) High-speed blending

[0041] Put the whole weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com