Photovoltaic frame double-material cutting system

A cutting system and frame technology, applied in metal sawing equipment, sawing machine devices, sawing machine attachments, etc., can solve the problems of low safety, high labor intensity, low cutting accuracy, etc., to improve the feeding speed and reduce labor intensity. , the effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

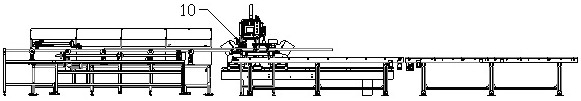

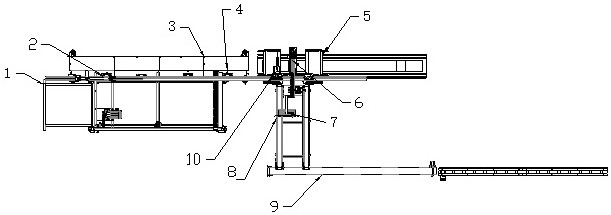

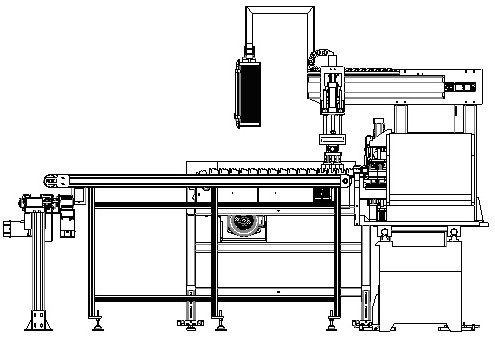

[0041] see Figure 1-Figure 8 , figure 1 A schematic diagram of the structure of a photovoltaic frame double-material cutting system is drawn. As shown in the figure, a photovoltaic frame double-material cutting system of the present invention includes a raw material feeding rack 1, a progressive feeding claw 2, a raw material feeding module 3, a jacking assembly 4, a double-head cutting saw 5, and a feeding manipulator 6. Cantilever operation electric control cabinet 7, unloading assembly line 8, distribution assembly line 9 and cutting positioning mechanism A10.

[0042] One side of the raw material feeding rack 1 is provided with a raw material feeding module 3, and the side of the raw material feeding module 3 close to the raw material feeding rack 1 is provided with a forward feeding claw 2, and the rear of the raw material feeding module 3 is provided with a cutting operation A cutting positioning mechanism A10 is set above the cutting operation table for positioning a...

Embodiment 2

[0053] see Figure 1-Figure 9 , Figure 9 What is drawn is a structural schematic diagram of another scheme of cutting positioning mechanism. The difference from Example 1 is that the cutting positioning mechanism B11 includes a pressing cylinder B11.1, a side pressing cylinder B11.2, a jacking cylinder B11.3, a fixed bracket pressing cylinder bracket 11.4 and a fixed bracket pressing cylinder , After the raw materials are delivered, the pressing cylinder B11.1 (with a pressure plate at the end) presses down, the jacking cylinder B11.3 (with a profiling block) and the side pressing cylinder B11.2 press the material tightly to ensure that the pressing is firm ; The pressing cylinder B11.1 (with a pressure plate at the end) is fixed on the fixed support pressing cylinder support 11.4, and the fixed support pressing cylinder support 11.4 is provided with a fixed support pressing cylinder.

[0054] Said fixed support pressing cylinder bracket 11.4 is made up of two horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com