A powder-adding dimple-making device for preforming the lower half mold of the fuel-free area of a spherical fuel element

A technology for spherical fuel elements and forming lower molds, which is applied in the field of nuclear technology devices, can solve the problems of long period of adding powder to nests, dust overflow production capacity, and inability to meet the large-scale production of spherical fuel elements, so as to protect the environment of the production workshop and prevent The effect of spilling and feeding evenly and loosely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

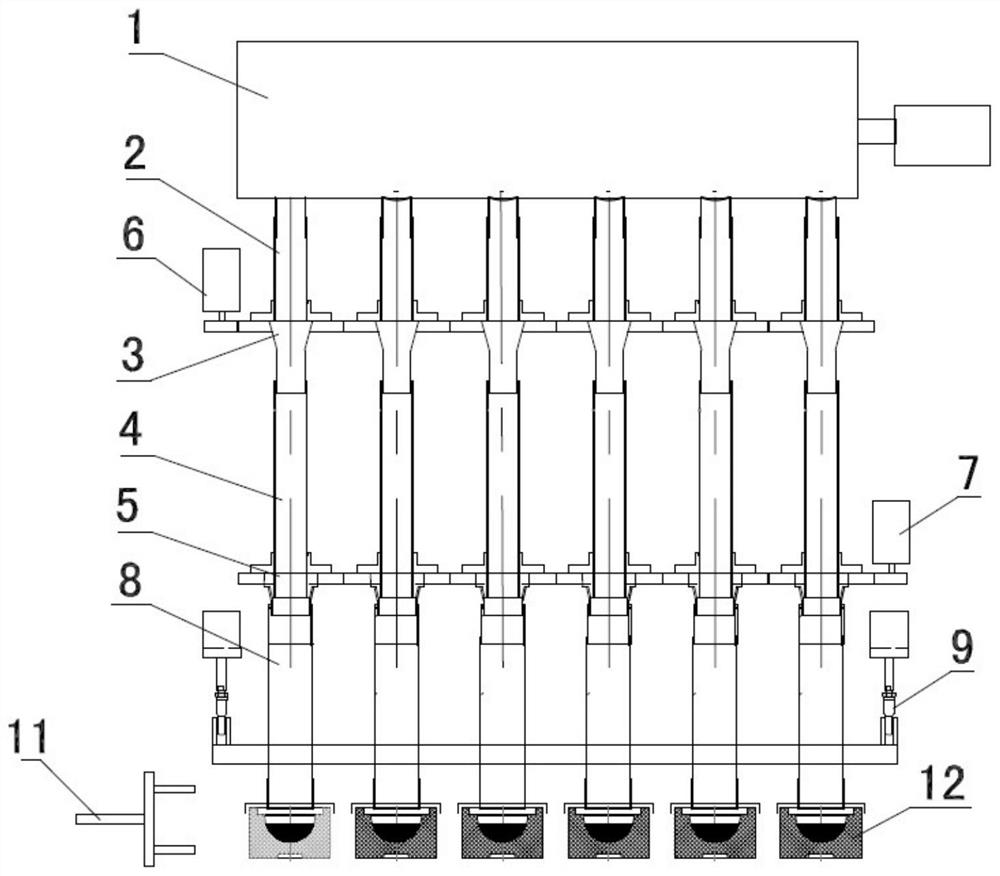

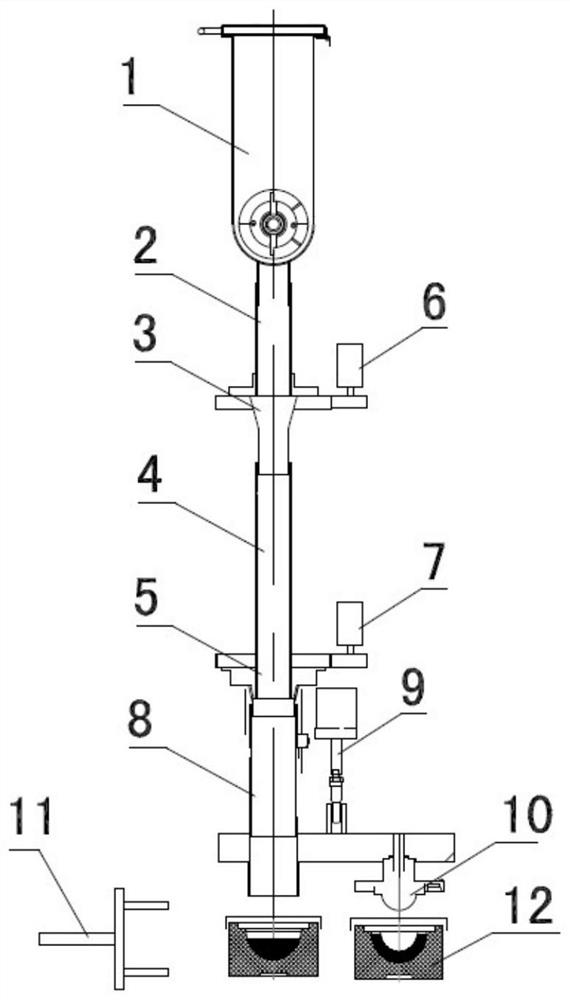

Method used

Image

Examples

experiment example 1

[0048] This experimental example uses a six-station powder-adding nest-making device. The diameters of the upper feed pipe 2, the straight feed pipe 4 and the lower feed pipe 8 are 56-58mm, and the rotation speeds of the upper screen and the lower screen are: 79 revolutions per minute, the upper screen is 10 mesh, the lower screen is 12 mesh, the time for adding powder to make nests is 21s, and the production capacity is 1028 per hour.

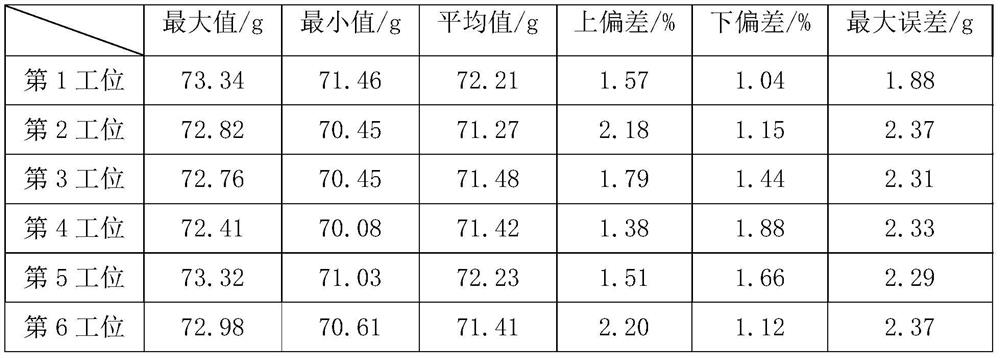

[0049] The test process is: the parallelism analysis of different tests at six stations, and the powder addition accuracy and error analysis of 15 test results at the same station. The specific test results and analysis errors are shown in Table 1 and Table 2 below. .

[0050] Table 1-Parallelism analysis of six stations in different experiments

[0051]

[0052] Table 2-Powdering accuracy and error analysis of 15 test results at the same station

[0053] Max / g Minimum value / g Average value / g Upper deviation / % Lower de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com