Preparation method of edible oil

A technology of edible oil and crude oil, which is applied in the direction of edible oil/fat, fat oil/fat refining, application, etc., can solve the problems of rapeseed oil flavor discount, oil yield reduction, etc., and achieve the effect of avoiding saponification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

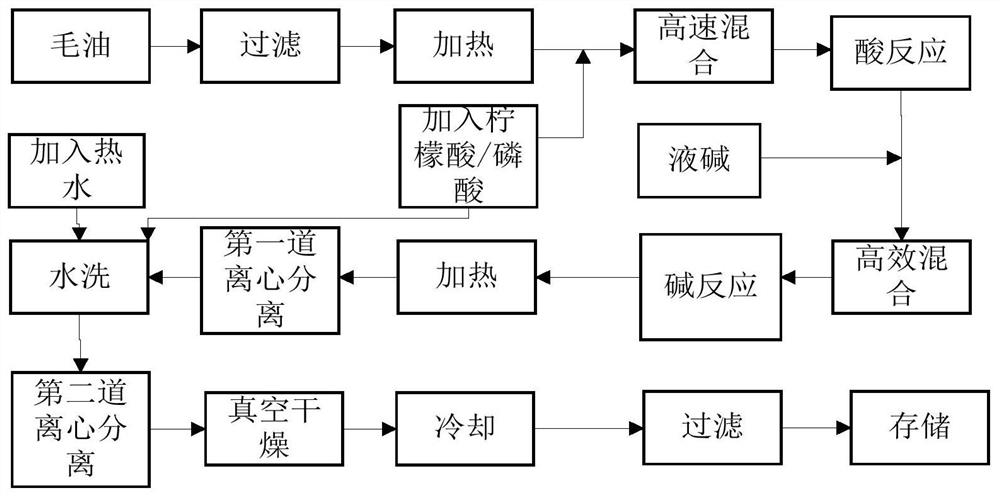

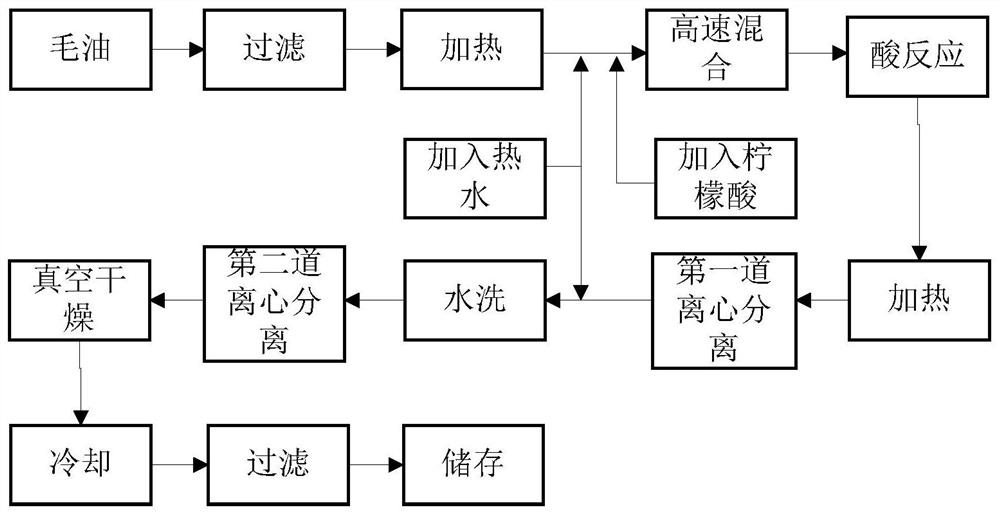

Method used

Image

Examples

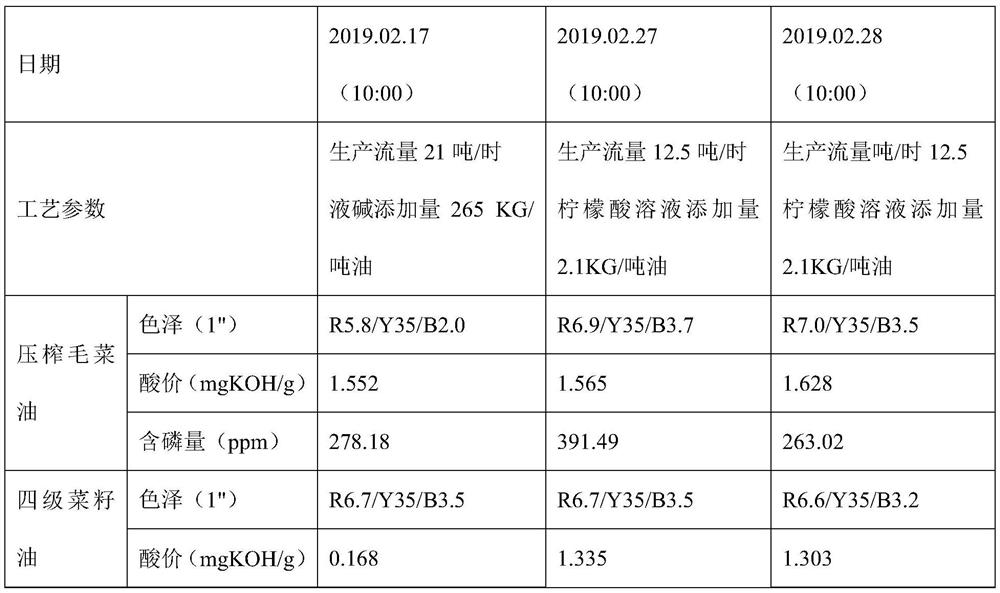

Embodiment 1

[0069] The rapeseed crude oil purchased from the oil mill or purchased from the oil mill is pumped to the workshop through the pump in the tank area, filtered to remove suspended impurities, then heated to 85°C by a heater, and then added with hot water at 90°C, the amount of hot water added 2% of the weight of the crude oil, then add a citric acid solution with a mass percentage of 50%, the addition of the citric acid solution is 0.2% of the oil weight, and then carry out high-speed mixing through a high-speed mixing reactor, and the rotating speed is 2940r / min. Under the action of stirring, the oil and citric acid are fully contacted, and then the crude oil mixed at high speed enters the acid reaction tank. The stirring speed of the acid reaction tank stirrer is 56r / min, and the acid reaction time is controlled for about 120 minutes. Hydrated phospholipids are fully converted into hydrated phospholipids;

[0070] Then the crude oil after the acid reaction is heated to 85.1°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com