Bundled steel wire core rod as well as metal pipe wall-reducing extension method and device

A metal pipe, steel wire core technology, applied in metal processing equipment, unloading mandrels, manufacturing tools, etc., can solve the problems of difficult processing and manufacturing, limited use range, long length, etc., to achieve simple and convenient production, increase strength and internal surface area , the effect of low stick force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

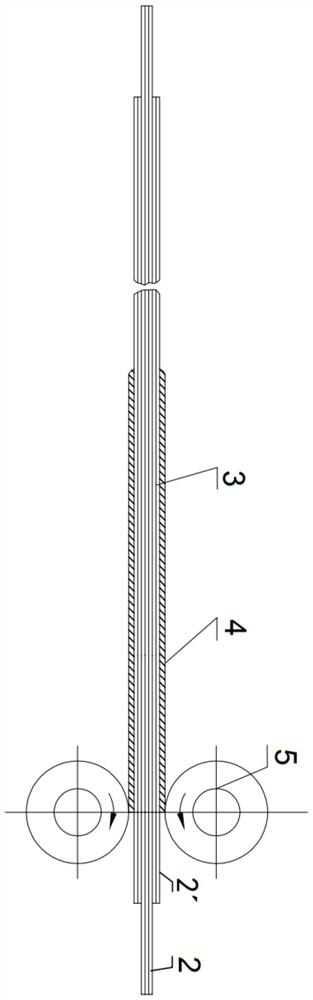

[0034] A magnesium alloy billet pipe with an outer diameter of 10 mm, a wall thickness of 1.5 mm, and a length of 240 mm is drawn through wall-reducing extension to obtain a magnesium alloy pipe with an outer diameter of 8 mm, a wall thickness of 0.5 mm, and a length of 900 mm.

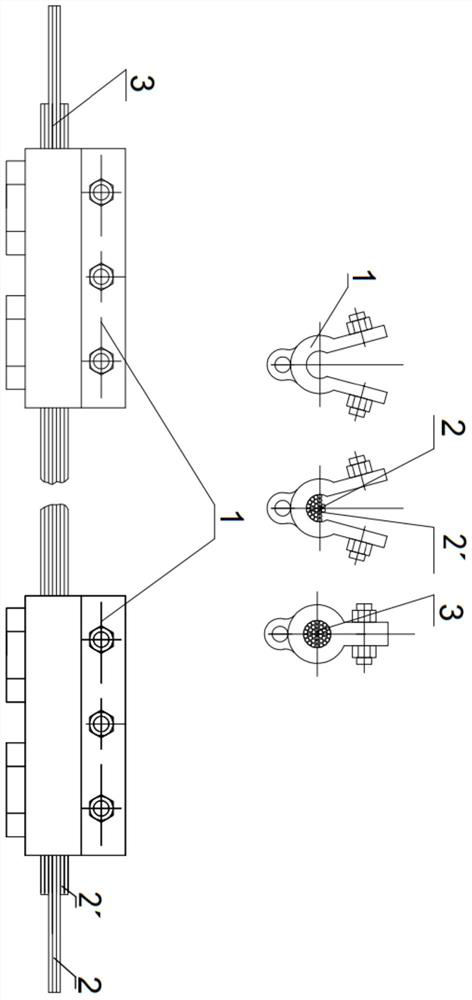

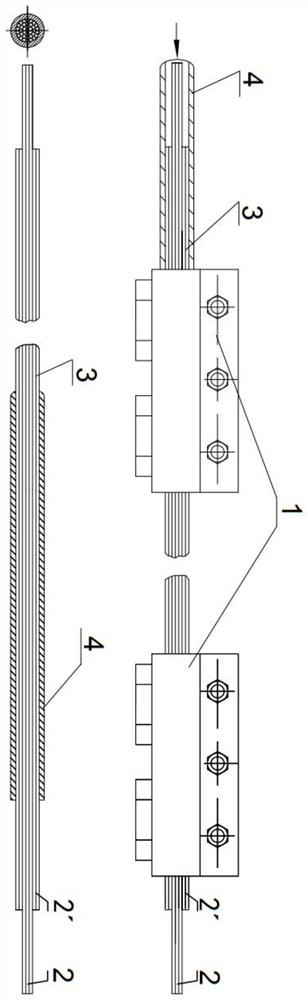

[0035] [1] 37 high-carbon steel wires with a diameter of 1 mm are used, 30 of which are 1000 mm in length, and 7 of which are 1100 mm in length. The steel wires are clamped together by 6 mandrel clamps, the 1100mm long steel wire is placed in the middle, and the 1000mm long steel wire is on the periphery to form a steel wire bundle, which becomes a bundled steel wire mandrel after clamping.

[0036] [2] Feed the bundled steel wire mandrels into the magnesium alloy billet tube material with an outer diameter of 10mm, a wall thickness of 1.5mm, and a length of 240mm. During the feeding process, the mandrel clamps are opened and removed one by one.

[0037] [3] Place the magnesium alloy billet tube that ...

Embodiment 2

[0042] A titanium alloy blank pipe with an outer diameter of 15mm, a wall thickness of 2mm, and a length of 240mm is drawn by wall reduction to obtain a titanium alloy pipe with an outer diameter of 12mm, a wall thickness of 1mm, and a length of 600mm.

[0043] [1] 32 high-carbon steel wires with a diameter of 1.5mm are used, 25 of which are 700mm in length, and 7 of which are 800mm in length. The steel wires are clamped together by 6 mandrel clamps, the 800mm long steel wire is placed in the middle, and the 700mm long steel wire is on the periphery to form a steel wire bundle, which becomes a bundled steel wire mandrel after clamping.

[0044] [2] Feed the bundled steel wire mandrel into the titanium alloy billet pipe with an outer diameter of 15mm, a wall thickness of 2mm, and a length of 240mm, and open and remove the mandrel clamps one by one during the feeding process.

[0045] [3] Put the titanium alloy billet pipe that penetrates the bundled steel wire mandrel on a thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com