Automatic processing equipment for sauce marinated food

A technology for automatic processing and food, applied in the direction of food science, etc., can solve the problems of not being able to process multiple foods at the same time, not suitable for mass production of food processing companies, and inability to distinguish food, etc., to achieve low labor intensity of workers, realize standardized production, Protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

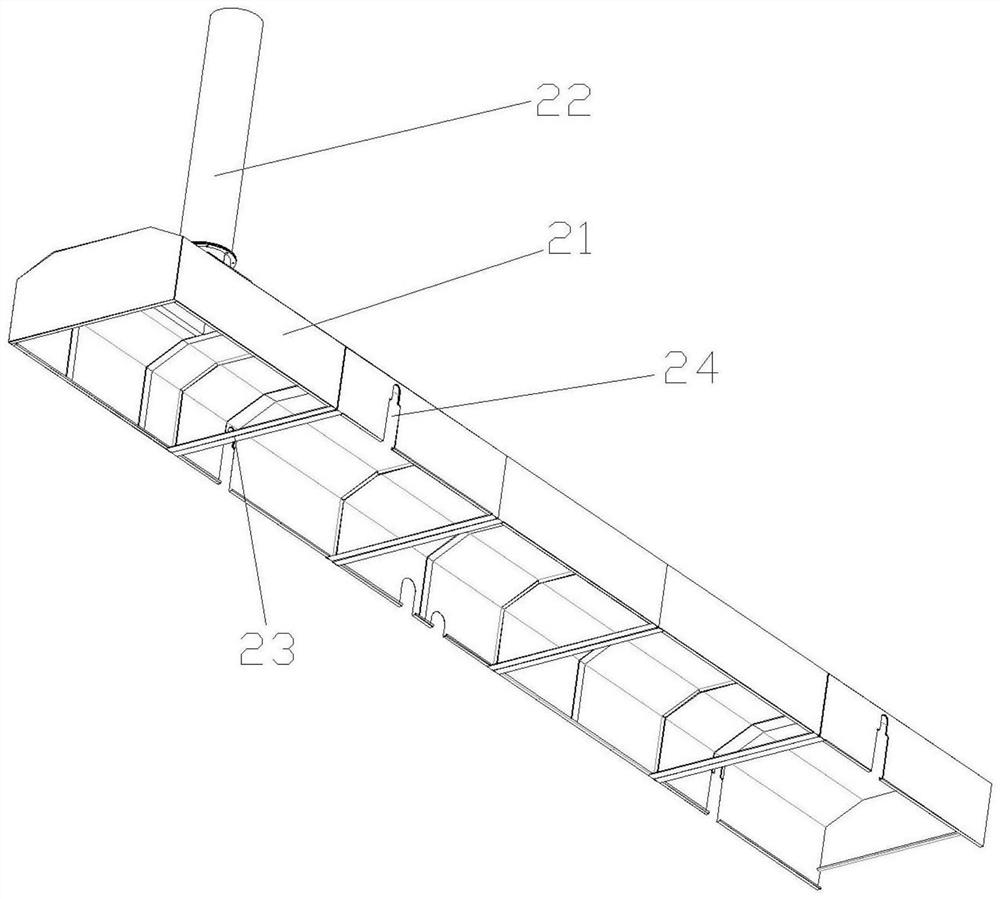

[0037] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating the specific structure, and the scale of the structure is not limited by the embodiment. In order to see the parts of each drawing clearly and reduce the lines, the attached Figure 5 In the above, the material devices are evenly distributed on the stewing line, only showing the head and tail structure of the material device in the stewing line, omitting the diagram of the material device in the middle; the same manual is attached Figure 7 with 8 Among them, the stainless steel mesh belt is evenly distributed on the chain, and the middle stainless steel belt is omitted.

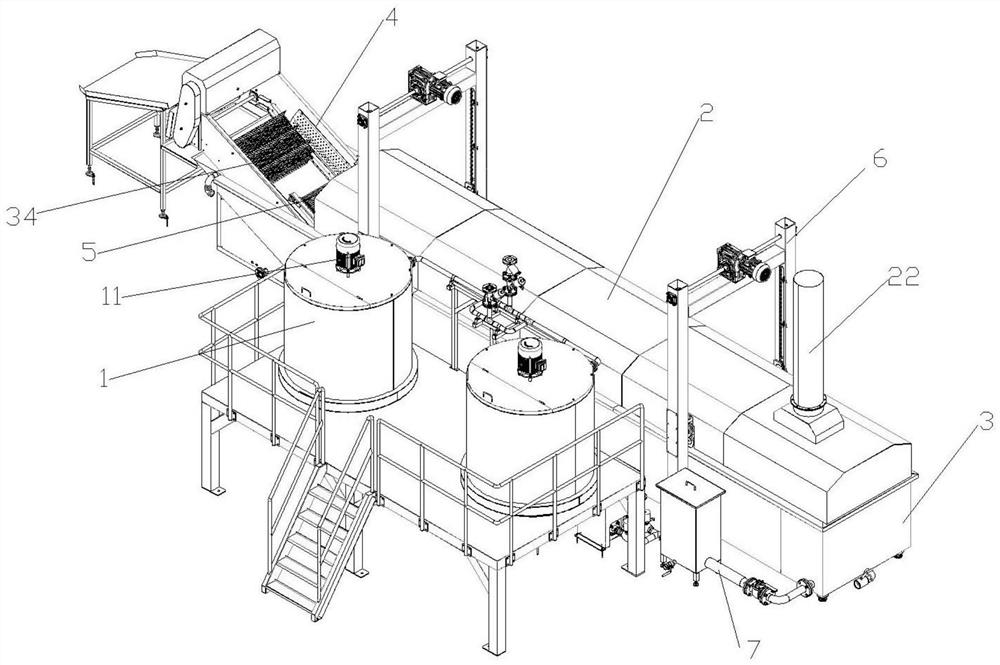

[0038] see Figure 1 to Figure 15As shown, an automatic processing equipment for stewed food with sauce, including stewed soup tank 1, upper cover 2, stewed cooking tank 3, stewed cooking line 4, anti-floating device 5, gantry lifting device 6; upper cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com