Production process of flavored kelp salad

A technology for cold-mixed kelp and production process, applied in the field of food processing, can solve the problems of easy color change from green to yellow, umami discount of kelp, influence on product appearance, etc., and achieve the effects of emerald green color, elimination of fishy smell, and shortening of foaming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

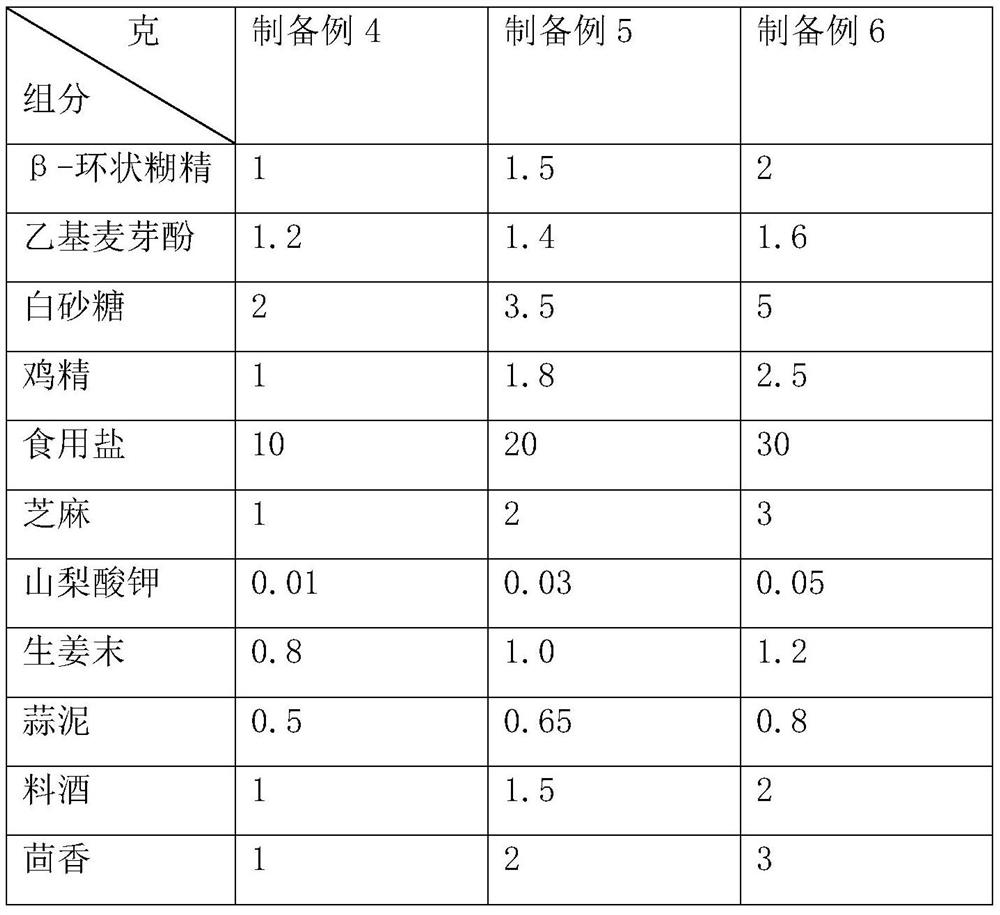

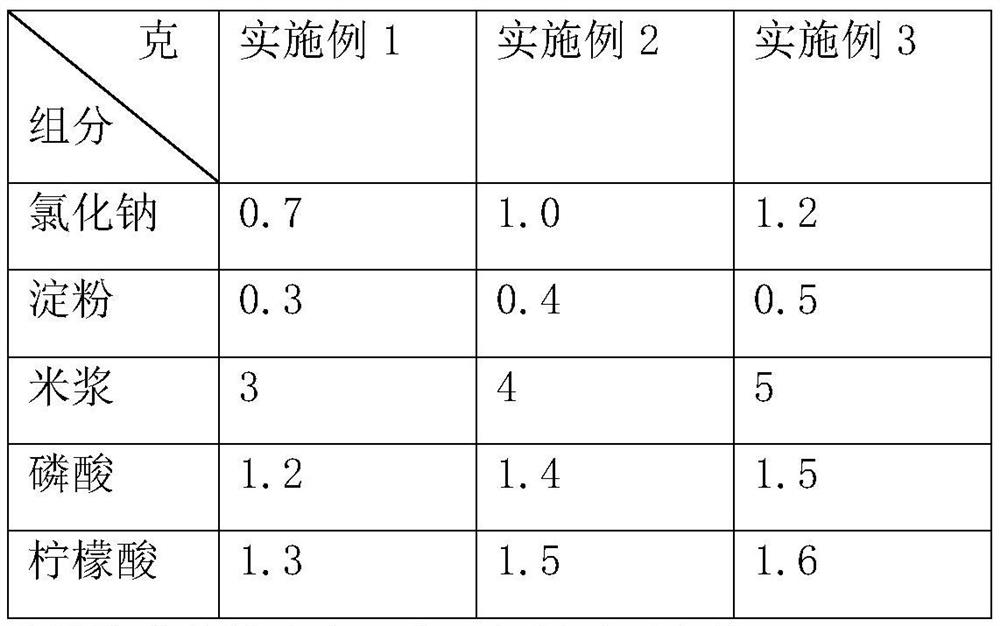

Examples

preparation example 1-3

[0039] The vanillin in preparation examples 1-3 is selected from the vanillin with the product number 01 sold by Taizhou Weiheng Food Co., Ltd.

preparation example 1

[0040] Preparation Example 1: Put fresh rice into a hot pot at 90°C and fry the surface slightly yellow, and cook the fried rice, water and vanillin in a mass ratio of 1:1.5:0.5, and cook The cooked rice was mixed with 8 times the amount of water at 50° C. to grind into a slurry to prepare rice slurry.

preparation example 2

[0041] Preparation Example 2: Put fresh rice into a hot pan at 95°C and fry the surface slightly yellow, and cook the fried rice, water and vanillin in a mass ratio of 1:1.8:0.6, and cook The cooked rice was mixed with 8 times the amount of water at 55° C. and pulverized into a slurry to prepare rice slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com