Atomic-scale surface and structure ultra-short pulsed light efficient processing method

An ultra-short pulse, processing method technology, applied in metal processing equipment, manufacturing tools, laser welding equipment and other directions, can solve the problems of difficult to achieve atomic-level high precision, destroy the atomic arrangement of the extreme surface layer, hinder the manufacturing process, etc., to achieve flexible improvement. performance and efficiency, avoid lattice damage, and improve the effect of extreme precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

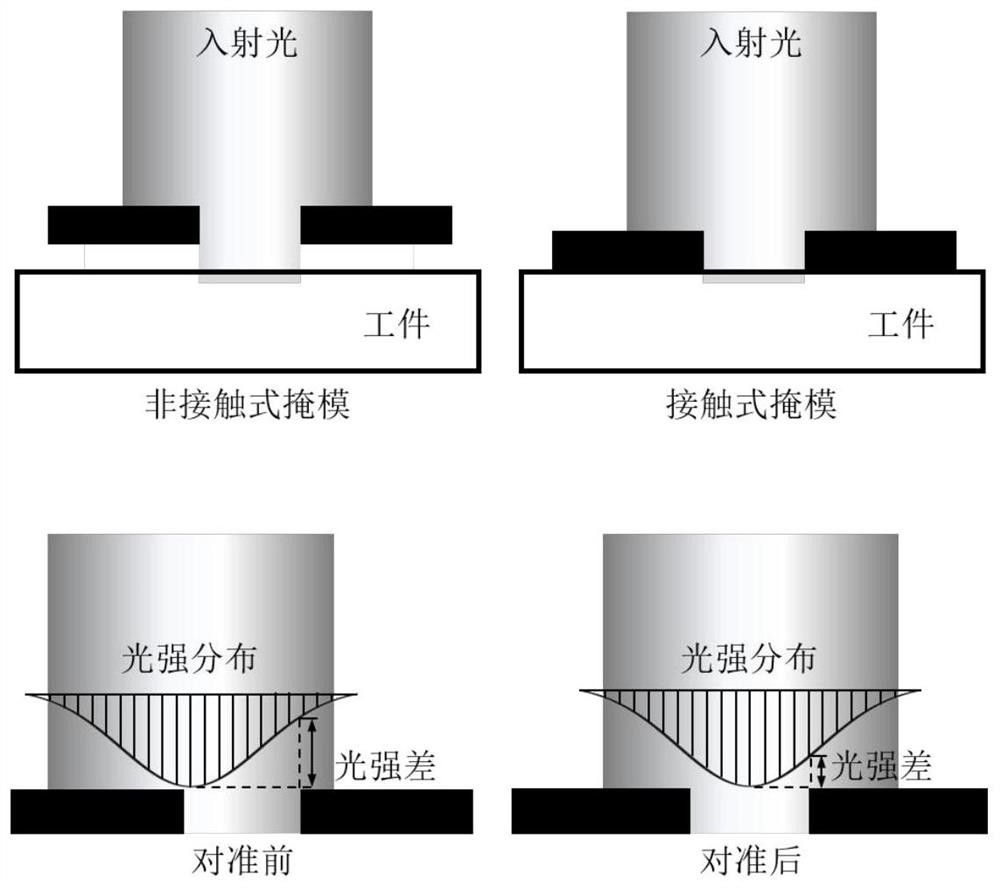

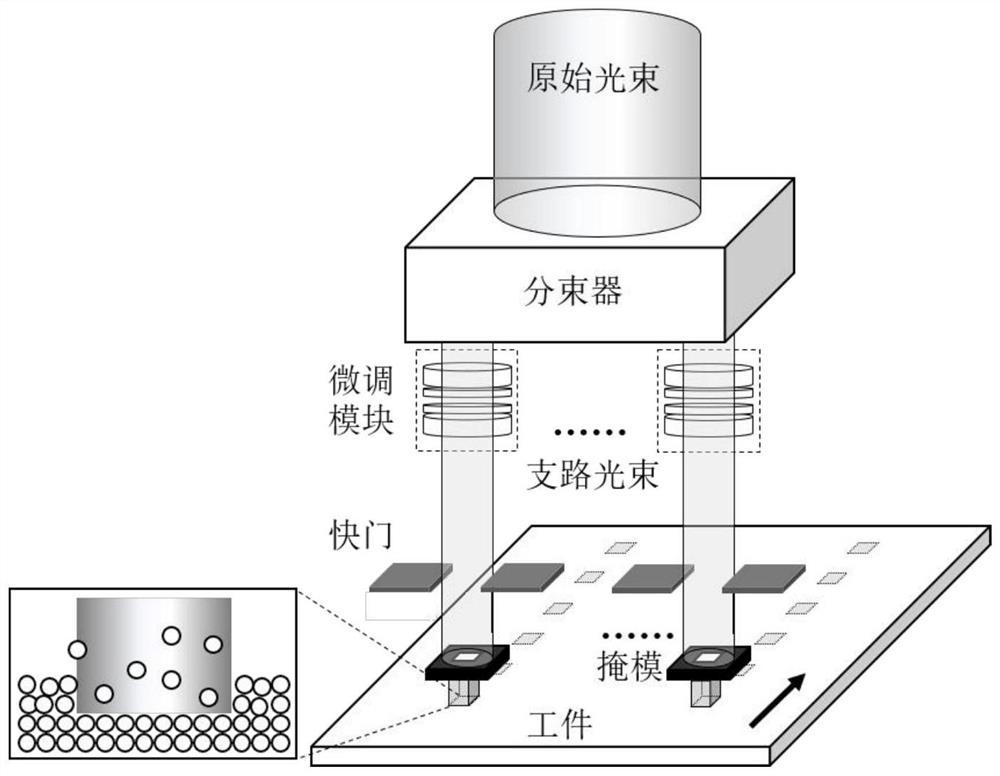

[0040] Combine below figure 2 Taking the surface atomic-level rectangular array processing of monocrystalline silicon (100) as an example, the specific implementation mode is explained:

[0041] 1. Pretreatment of workpiece surface;

[0042] 2. According to the material parameters and the number of atomic layer removal N, the upper limit of wavelength λ is determined by formulas (1) and (2) max And initial value of energy density

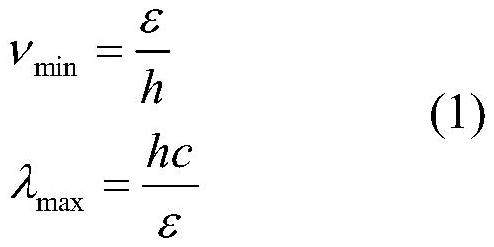

[0043] Assuming that the average chemical bond energy of atoms on the surface of the material is ε, the lower limit of the theoretical frequency of incident light is ν min And the corresponding upper wavelength λ max Respectively

[0044]

[0045] Where h is Planck's constant and c is the speed of light in vacuum. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com