Preparation method of silver nanowire flexible transparent conductive film based on phenolic resin

A technology of transparent conductive film and silver nanowire, which is applied in the manufacture of equipment for conducting/semiconducting layers, conducting layers on insulating carriers, cable/conductor manufacturing, etc., and can solve the problem of silver nanowire layer and polydimethyl Silicone substrates have poor bonding performance, silver nanowire layer surface roughness, silver nanowires are easily oxidized, etc., to achieve low price, low overall cost, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

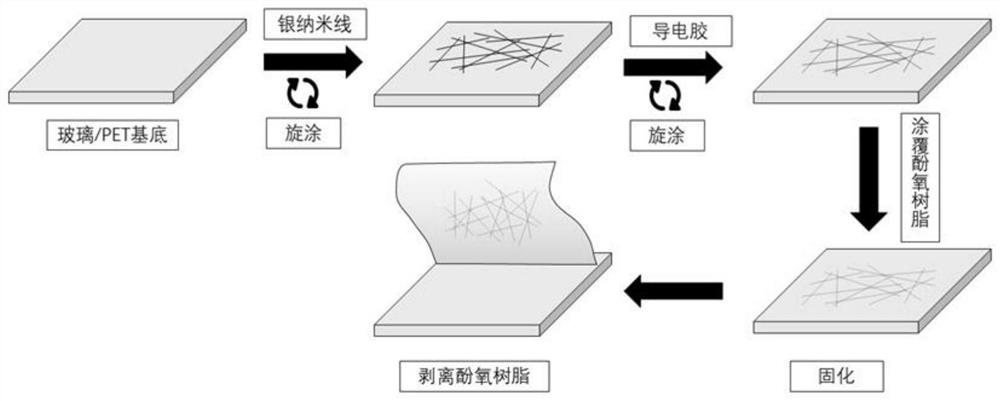

[0033] The preparation method of the silver nanowire flexible transparent conductive film based on phenolic resin according to the embodiment of the present invention comprises the following steps:

[0034] (1) Treatment of transparent conductive film substrate:

[0035] Sonicate a 40×40mm glass substrate in deionized water, ethanol, and acetone for 15 minutes respectively, and dry it with nitrogen to obtain a processed substrate.

[0036] (2) Preparation of silver nanowire transparent conductive film:

[0037] Disperse the silver nanowires in ethanol to obtain a silver nanowire dispersion with a concentration of 1 mg / mL;

[0038] Get an appropriate amount of silver nanowire dispersion liquid on the processed substrate obtained in step (1) for spin coating, spin coating for 5 seconds at a speed of 600 rpm, then spin coating for 15 seconds at a speed of 1500 rpm, spin coat one layer of silver nano wires, and then Dry naturally (to constant weight) in the air to obtain a silve...

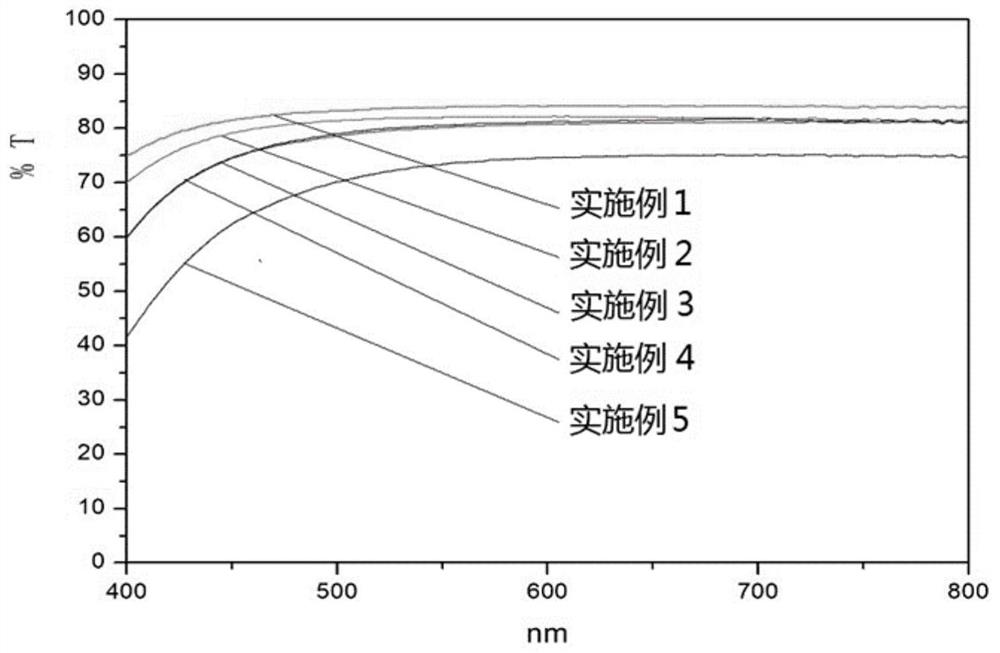

Embodiment 2

[0044] The preparation method of the silver nanowire flexible transparent conductive film based on phenolic resin according to the embodiment of the present invention comprises the following steps:

[0045] (1) Treatment of transparent conductive film substrate:

[0046] Sonicate a 40×40mm glass substrate in deionized water, ethanol, and acetone for 15 minutes respectively, and dry it with nitrogen to obtain a processed substrate;

[0047] (2) Preparation of silver nanowire transparent conductive film:

[0048] Disperse the silver nanowires in ethanol to obtain a silver nanowire dispersion with a concentration of 1 mg / mL;

[0049] Get an appropriate amount of silver nanowire dispersion liquid on the processed substrate obtained in step (1) for spin coating, spin coating for 5s at a speed of 600rpm, then spin coating for 15s at a speed of 1500rpm, spin coat two layers of silver nanowires, and then Dry naturally (to constant weight) in the air to obtain a silver nanowire trans...

Embodiment 3

[0055] The preparation method of the silver nanowire flexible transparent conductive film based on phenolic resin according to the embodiment of the present invention comprises the following steps:

[0056] (1) Treatment of transparent conductive film substrate:

[0057] Sonicate a 40×40mm PET substrate in deionized water, ethanol, and acetone for 15 minutes respectively, and dry it with nitrogen to obtain a processed substrate;

[0058] (2) Preparation of silver nanowire transparent conductive film:

[0059] Disperse the silver nanowires in ethanol to obtain a silver nanowire dispersion with a concentration of 1 mg / mL;

[0060] Get an appropriate amount of silver nanowire dispersion liquid on the processed substrate obtained in step (1) for spin coating, spin coating with a speed of 600rpm for 5s, and then spin coat with a speed of 1500rpm for 15s, spin coat 3 layers of silver nanowires, and then Dry naturally (to constant weight) in the air to obtain a silver nanowire tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com