High-temperature sensor based on FBG and working and manufacturing method of high-temperature sensor

A high-temperature sensor and sensor body technology, which is applied to thermometers, instruments, thermometers, etc. that change physically/chemically, can solve the problems of sensor function and size, low reliability, low sensitivity, etc., and achieve a wide range of use. Effect of small size and high temperature measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

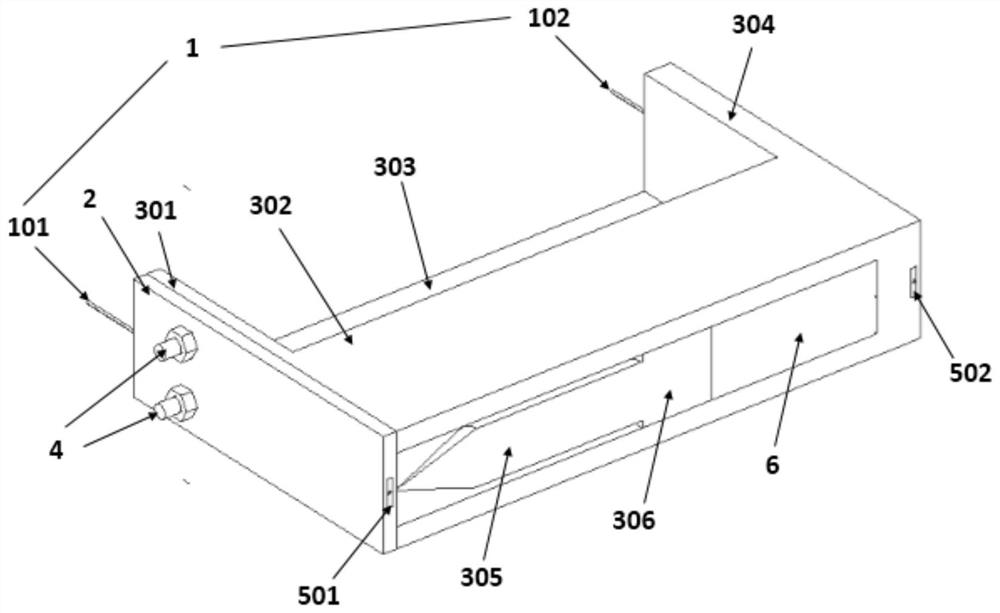

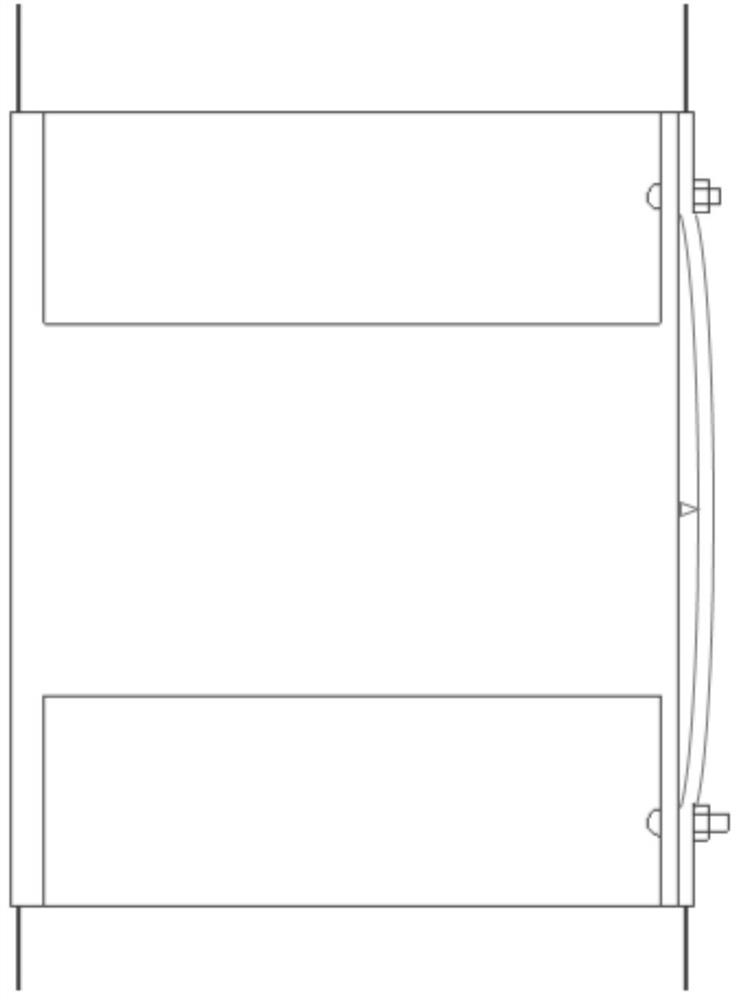

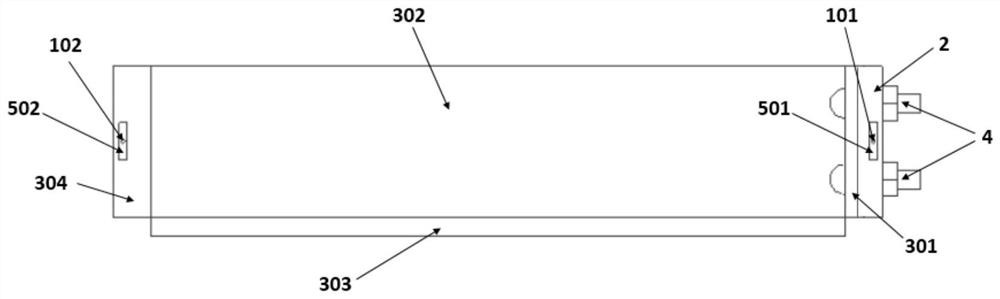

[0090] Such as figure 1 , a high temperature sensor based on FBG, the sensor includes a bare optical fiber 1, a first sensitization FBG package 2, a connecting arm 301, a hollow chamber 302, a fixed base 303, a second sensitization FBG package 304, a push rod 305 , a piston 306 , a nut 4 , a first sensitizing FBG polyimide curing thin strip 501 , a second sensitizing FBG polyimide curing thin strip 502 , and a high temperature resistant rubber 6 .

[0091] The sensitized FBG and PI solution are solidified in the polyimide thin tape, wherein, the two ends of the first sensitized FBG packaging sheet are respectively fixed to the two connecting arms by bolts.

[0092] The temperature compensation FBG is located in the second sensitization-increasing FBG packaging chip, and the temperature-measuring FBG is located in the first sensitization-increasing FBG packaging chip.

[0093] One side of the sensor is the first sensitization FBG packaging sheet 2, and its two ends are fixed w...

Embodiment 2

[0095] A manufacturing method of a high-precision FBG high-temperature sensor includes fixing the FBG in a tube furnace, closing the tube furnace, inserting high-temperature cotton at both ends, and completing the annealing process.

Embodiment 3

[0097] Repeat Example 2, except that the high temperature causes thermal expansion of the high-temperature-resistant rubber, and the ejector pin acts on the first sensitized FBG packaging sheet, so that the temperature-measuring FBG inside it can recognize its bending tension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com