High-efficiency FBG high-temperature sensor and working and manufacturing method thereof

A high-temperature sensor and sensor technology, which is applied in the direction of instruments, thermometers, scientific instruments, etc., can solve the problems of excessive sensor function and size, low sensitivity, low reliability, etc., and achieve the elimination of wavelength nonlinear drift, high reflected light power, The effect of high temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

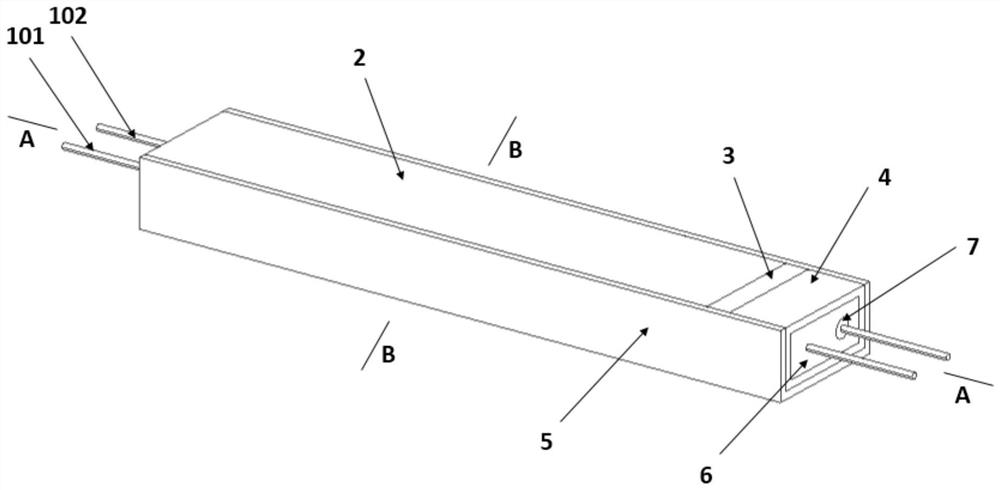

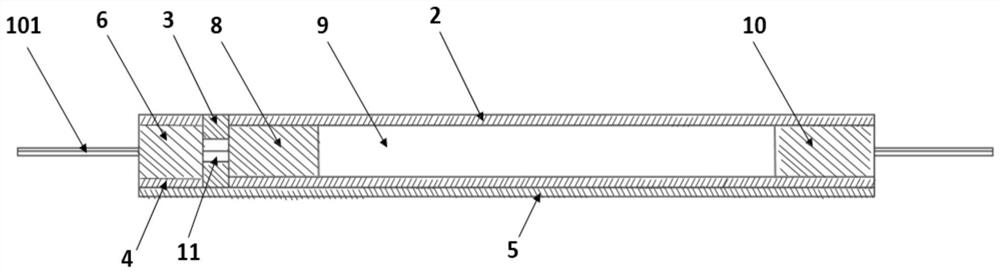

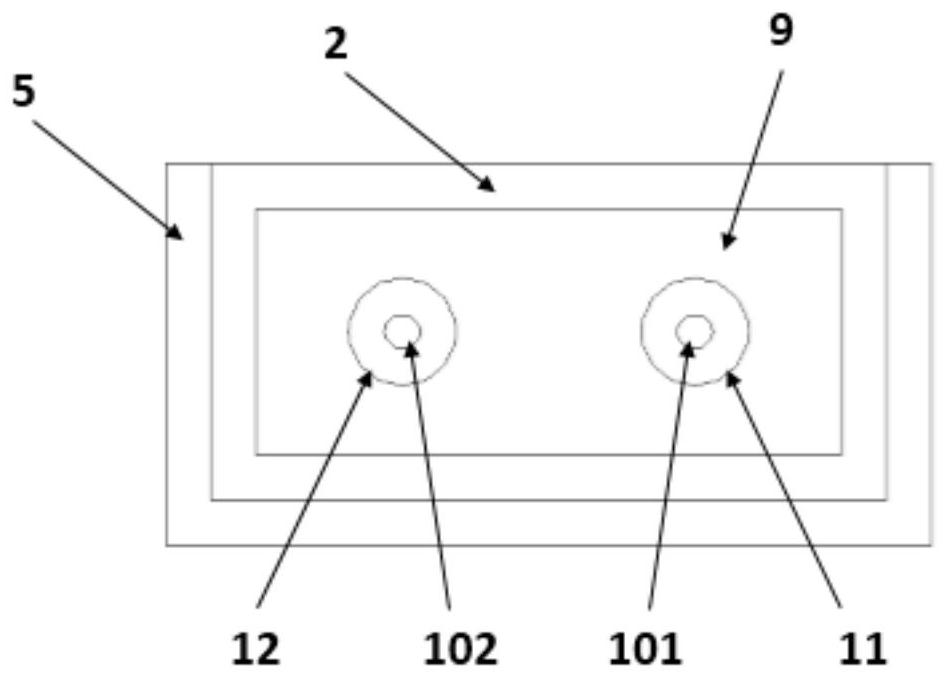

[0090] A high-efficiency FBG high-temperature sensor, the sensor includes a first sensitization FBG 101, a second sensitization FBG 102, a first package shell 2, a thermal bimetal 3, a second package shell 4, a guide rail base 5, and a third anchor Structure 6 , third thermal insulation sleeve 7 , second anchor structure 8 , thermal insulation area 9 , first anchor structure 10 , first thermal insulation sleeve 11 , and second thermal insulation sleeve 12 .

[0091] The optical fiber passes through the first thermal insulation sleeve 11 and the second thermal insulation sleeve 12, and the outer surface of the thermal insulation sleeve is filled with thermal insulation material, and the outer surface of the thermal insulation material is an encapsulation casing sleeve.

[0092] One end of the first sensitizing FBG101 is anchored by the first anchoring structure 10, and the other end is anchored by the third anchoring structure 6 after passing through the first insulation sleeve ...

Embodiment 2

[0094] A manufacturing method of a high-efficiency FBG high-temperature sensor includes fixing the FBG in a tube furnace, closing the tube furnace, inserting high-temperature cotton at both ends, and completing the annealing process.

Embodiment 3

[0096] Embodiment 2 is repeated, except that the thermal bimetal sheet is thermally deflected, thereby acting on the third anchoring structure 6, so that the temperature-measuring FBG in the first thermal insulation sleeve can recognize this force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com