Bridge deck structure of railway steel truss girder

A steel truss girder and railway technology, applied in bridges, bridge parts, bridge construction and other directions, can solve problems such as easy blockage of drainage pipes, and achieve the effects of improving connection stability, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

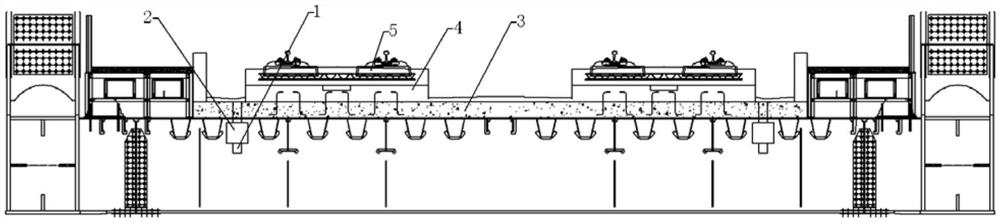

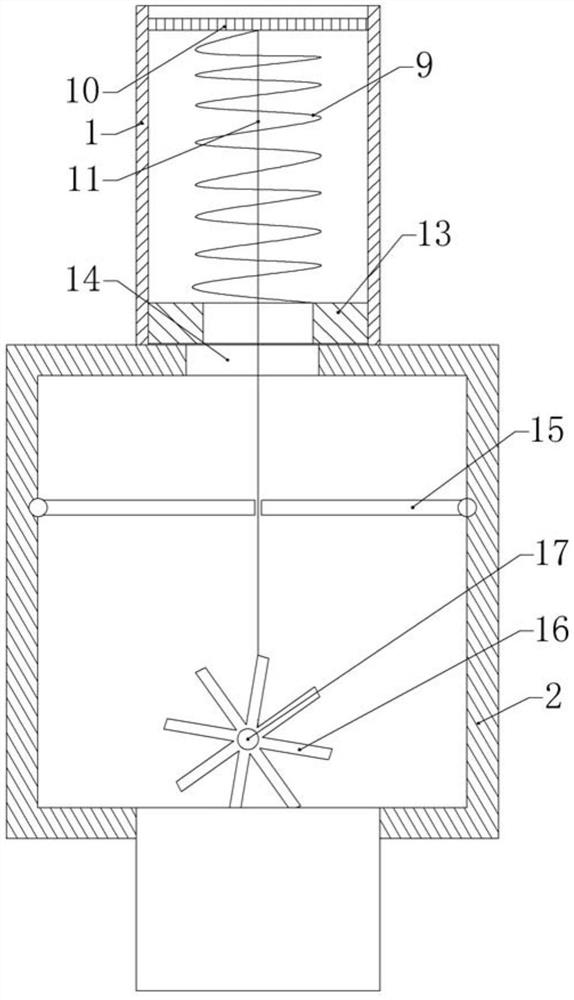

[0034] like figure 1 As shown, a bridge deck structure of a railway steel truss includes a bridge deck 3, a number of sleepers 4 are fixed on the bridge deck 3 (bolts can be used), and rails 5 are erected on the sleepers 4, and the rails 5 can be threaded spikes or The bolts are fixed on the sleeper 4. Several drainage pipes 1 are vertically installed on the bridge deck 3 , and both ends of the drainage pipes 1 penetrate through the bridge deck 3 . like figure 2 As shown, a drain 10 is provided at the water inlet of the drain pipe 1 , and a cleaning mechanism for cleaning the sundries on the drain 10 is installed on the drain pipe 1 .

[0035] like figure 2 As shown, the cleaning mechanism includes a rectangular power box 2, and the power box 2 is connected to the drain pipe 1. Specifically, the power box 2 is sealed and connected to the drain pipe 1, and the top and the top of the power box 2 are provided with through holes 14 and the drain pipe. Tube 1 is connected. A...

Embodiment 2

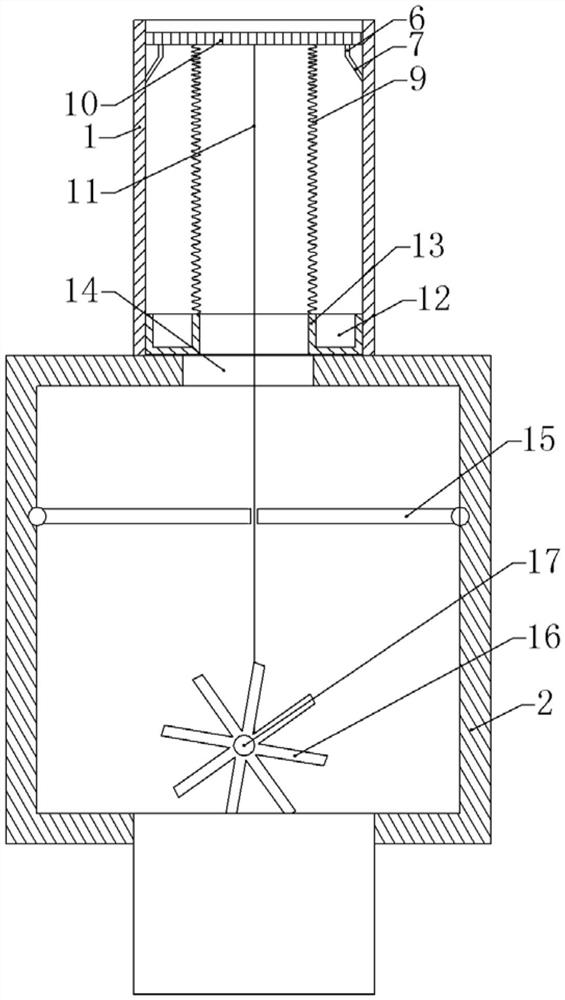

[0041] like image 3 As shown, the difference between this embodiment and the first embodiment is that a plurality of scrapers are glued to the bottom of the slip screen 10, and the scrapers are made of plastic. The scraper includes a vertical portion 6 connected to the drain screen 10 and an inclined portion 7 inclined to the outside of the drain screen 10 . The vertical portion 6 and the inclined portion 7 are integrally formed. The outer diameter of the support frame 13 is the same as the inner diameter of the drain pipe 1 . The support frame 13 is provided with an annular collecting groove 12 , the top of the collecting groove 12 is open, and the scraper can be accommodated in the collecting groove 12 .

[0042]In this embodiment, when the drain 10 is pulled down by the pull rope 11 , the scraper on the drain 10 can scrape off the dirt adhering to the inner wall of the drain pipe 1 , thereby realizing the cleaning of the drain pipe 1 . The scraped dirt can be dropped into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com