Super-hydrophobic paint with super-strong mechanical properties and preparation method thereof

A technology with mechanical properties and super-hydrophobicity, applied in coatings, epoxy resin coatings, polyether coatings, etc., can solve the problems of weak mechanical properties, difficult to prepare the surface of various substrates, etc. Wetting-response properties, the effect of increasing the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

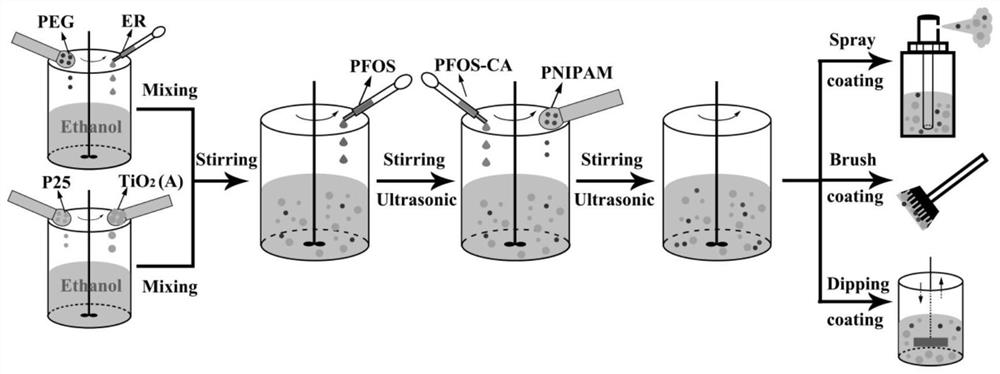

[0028] refer to figure 1 , the present invention also provides the preparation method of the superhydrophobic paint of above-mentioned super strong mechanical property, comprises the following steps:

[0029] Step S1, weighing 1-10 parts of epoxy resin and 0.4-2.4 parts of polyethylene glycol in parts by mass, mixing them, adding absolute ethanol, and magnetically stirring;

[0030] Step S2, adding absolute ethanol to 1 to 2.5 parts of titanium dioxide in parts by mass, and magnetically stirring;

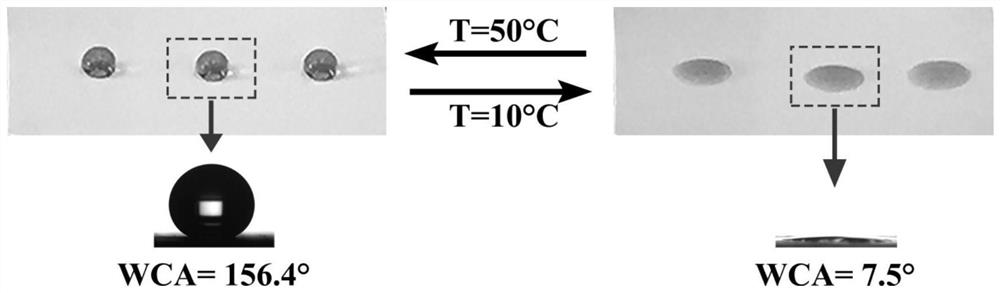

[0031] Step S3, mixing the solution of step S1 and the solution of step S2, adding 1.6-5 parts of 1H,1H,2H,2H-perfluorooctyltriethoxysilane, 0.02-0.12 parts of poly( N-isopropylacrylamide), 0.1-1.2 parts of fluorosilane, 0.2-1.2 parts of curing agent, magnetic stirring, and ultrasonic treatment to obtain super-hydrophobic paint.

Embodiment 1

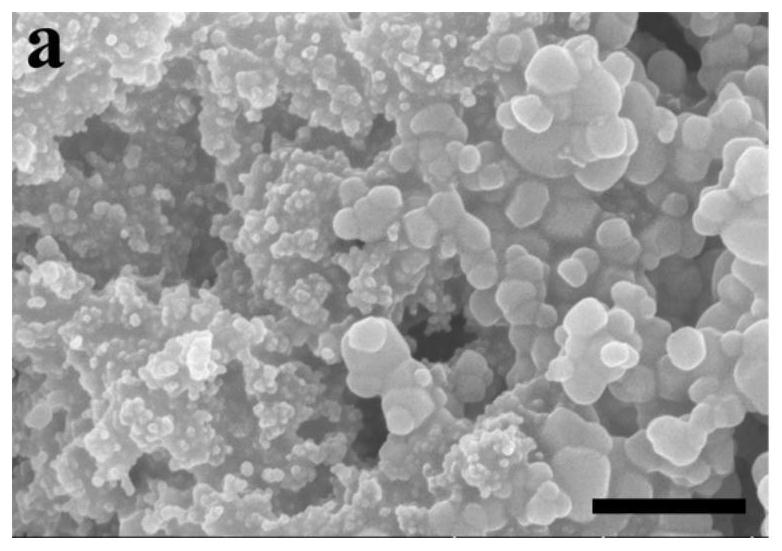

[0034] In a 100mL beaker, add 5g of epoxy resin and 2.0g of polyethylene glycol, then add 30mL of absolute ethanol solution, then stir in a magnetic stirrer for 15min; weigh 1.5g of titanium dioxide particles (P25 titanium dioxide and 200nm anatase The mass ratio of ore titanium dioxide is 2.0:1) into a 250mL blue-necked bottle, then add 70mL of absolute ethanol solution, and then magnetically stir for 15min; mix the epoxy resin and titanium dioxide solution, then add 3.5g1H, 1H, 2H,2H-Perfluorooctyltriethoxysilane, magnetically stirred for 15min, ultrasonically treated for 15min, repeated stirring and ultrasonically for 2 times; then added 0.1g poly(N-isopropylacrylamide), stirred and ultrasonically treated for 5min each ; Finally, add 0.6g fluorosilane and 0.8g ethylenediamine, stir magnetically for 5min, ultrasonicate for 10min, and stir magnetically for 5min again to obtain a superhydrophobic paint.

[0035] In Example 1, every 1 g is one serving.

[0036] The paint prepa...

Embodiment 2

[0042] In a 100mL beaker, add 8g of epoxy resin and 0.6g of polyethylene glycol, then add 30mL of absolute ethanol solution, and then stir in a magnetic stirrer for 15min; weigh 2.0g of titanium dioxide particles (P25 titanium dioxide and 200nm anatase The mass ratio of ore titanium dioxide is 1:1) into a 250mL blue bottle, then add 70mL of absolute ethanol solution, and then magnetically stir for 15min; mix the epoxy resin and titanium dioxide solution, then add 2.0g1H, 1H, 2H,2H-Perfluorooctyltriethoxysilane, magnetic stirring for 15min, ultrasonic treatment for 15min, stirring and ultrasonic treatment repeated twice; then add 0.05g poly(N-isopropylacrylamide), stirring and ultrasonic treatment for 5min each ;Finally, add 0.5g fluorosilane and 1.0g hexamethylenediamine, stir magnetically for 5min, treat with ultrasonic for 10min, and stir magnetically again for 5min to obtain the superhydrophobic paint.

[0043] In Example 2, every 1 g is one serving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com