System and process for treating THPC-containing wastewater

A treatment system and treatment process technology, applied in the field of comprehensive treatment of flame retardant wastewater, can solve the problems of poor COD and ammonia nitrogen removal, lack of nutrient sources in the biochemical section, etc., to ensure long-term stable operation, strong protection, and removal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

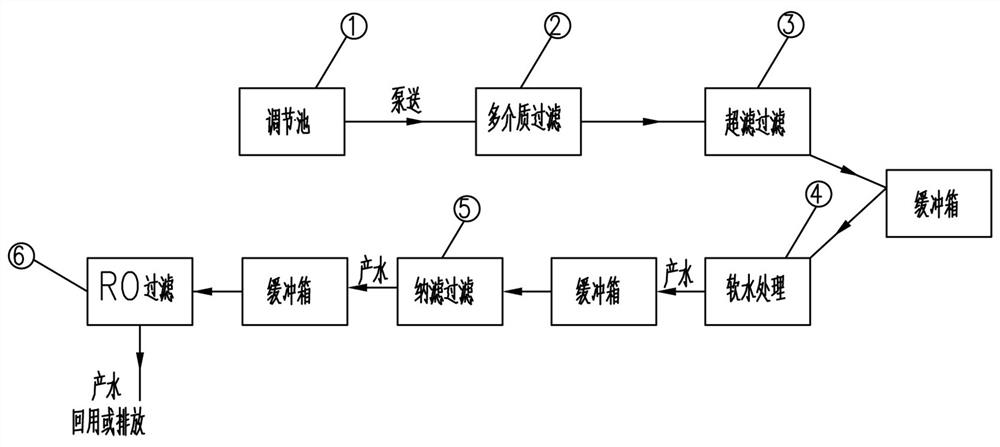

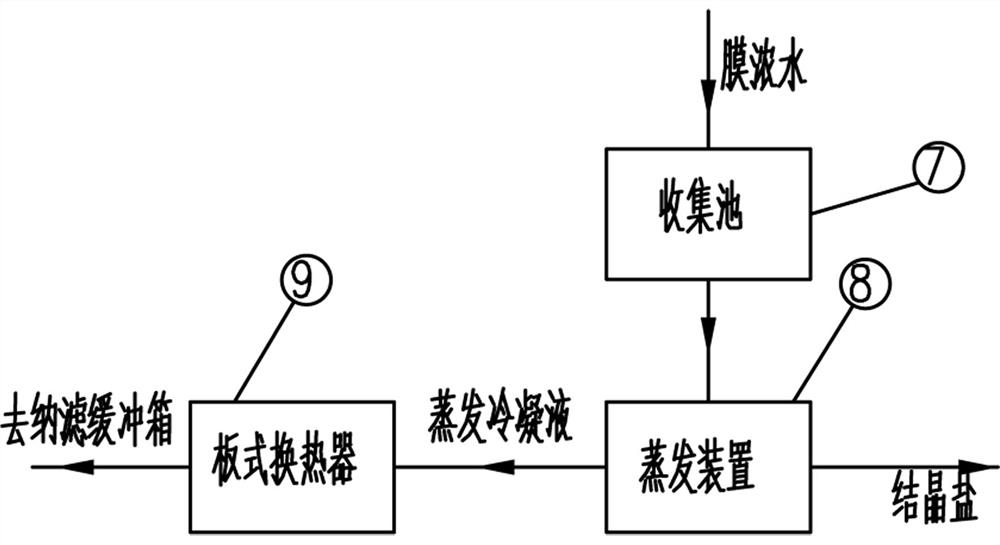

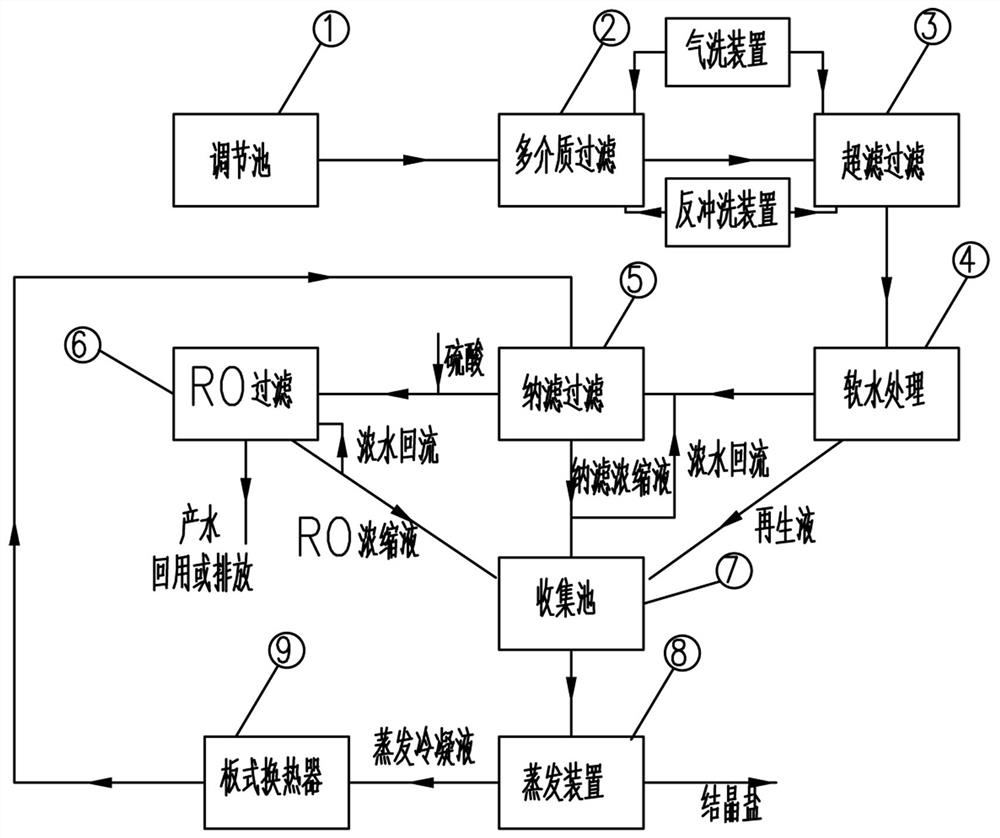

[0033] Such as image 3 As shown, a THPC-containing wastewater treatment system includes a regulating tank 1, which is connected to a multi-media filtration device 2, an ultrafiltration device 3, a water softening device 4, a nanofiltration membrane system 5, and an RO membrane system through a pipeline 6 Connected in sequence, the concentrated water outlet of the RO membrane system 6 is connected to the concentrated water collection tank 7 through the pipeline, and the concentrated water collection tank 7 is connected to the evaporation device 8 and the plate heat exchanger 9 through the pipeline in sequence.

[0034] Preferably, the condensate water outlet of the plate heat exchanger 9 is connected to the forward water buffer tank of the nanofiltration membrane system 5 through a pipeline.

[0035] Preferably, the concentrated water discharge port of the nanofiltration membrane system 5 and the regenerated liquid discharge port of the water softening device 4 are connected to the...

Embodiment 2

[0041] The system of Example 1 was used for the treatment process and treatment method of THPC-containing wastewater, and the details are as follows: the THPC-containing wastewater is collected and enters the adjustment tank 1, its pH is 9.8, total phosphorus 63.85mg / L, COD 755mg / L, ammonia nitrogen 152mg / L, The SS 186mg / L is transported to the multi-media filter device 2 by a lift pump to filter, and most of the suspended solids are filtered out. The SS content is 28mg / L, and then it enters the ultrafiltration device 3 for filtration. The ultrafiltration product water SS content is 0.8mg / L, after the ultrafiltration product water enters the buffer tank, it is pumped to the water softening device 4 to remove calcium and magnesium ions, and then pumped to the nanofiltration device 5 for filtration, the operating pressure is 1.8Mpa, the total phosphorus of the nanofiltration product water is 12.7mg / L, COD183 .5mg / L, ammonia nitrogen 129.6mg / L, part of the concentrated water is re...

Embodiment 3

[0043] The system of Example 1 was used to process the THPC-containing wastewater treatment process and treatment method. The THPC-containing wastewater was collected and entered into the regulating tank 1. Its pH was 9.2, total phosphorus 85.5mg / L, COD 683mg / L, ammonia nitrogen 185mg / L, SS 144mg / L Use a lift pump to transport it to the multi-media filter device 2 to filter, filter out most of the suspended solids, the SS content is 15mg / L, and then enter the ultrafiltration device 3 to filter, the ultrafiltration product water SS content is 0.4mg / L, After the ultrafiltration product water enters the buffer tank, it is pumped to the water softening device 4 to remove calcium and magnesium ions, and then pumped to the nanofiltration device 5 for filtration. The operating pressure is 1.6Mpa, the nanofiltration recovery rate is 90%, and the total phosphorus of the nanofiltration product water is 15.2 mg / L, COD137.6mg / L, ammonia nitrogen 141.5mg / L, part of the concentrated water is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com