Preparation method and application of expanded graphite with preferential adsorption performance on aromatic compounds

A preferential adsorption, aromatic technology, used in the preparation of expanded graphite, the preparation of expanded graphite, can solve problems such as unfavorable, light weight and loose adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

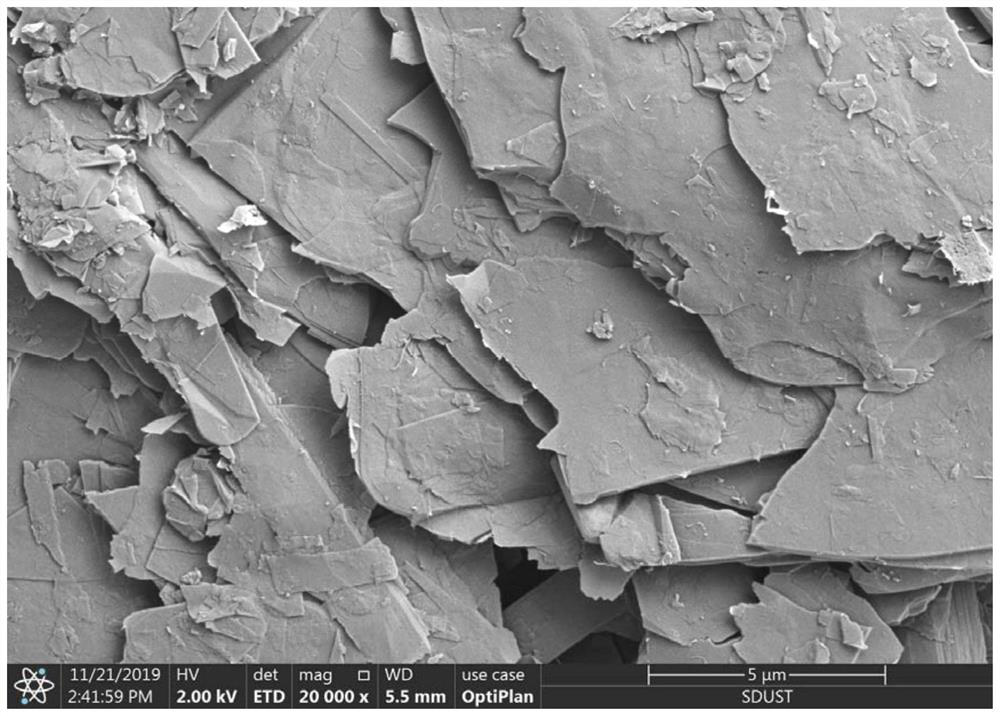

Image

Examples

Embodiment 1

[0035] A method for preparing expanded graphite with preferential adsorption properties for aromatic compounds, comprising the following steps:

[0036] Natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.) 5 grams, add 10 ml of NMP, 12 ml of sulfolane and 15 ml of water, shake and mix, add 2 ml of concentrated sulfuric acid, shake and mix , add 0.5 g of potassium permanganate, shake, dissolve and mix evenly, ultrasonicate for 5 minutes, and then shake at room temperature for 1 hour;

[0037] Add hydrogen peroxide dropwise under stirring until the brown color and the purple color of the supernatant disappear, then add 2 ml in excess;

[0038] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and intercalated graphite are transferred to an oven at 105°C for drying;

[0039] The intercalated graphite is transferred to a beaker, and 500 watts of microwave radiation is irradiat...

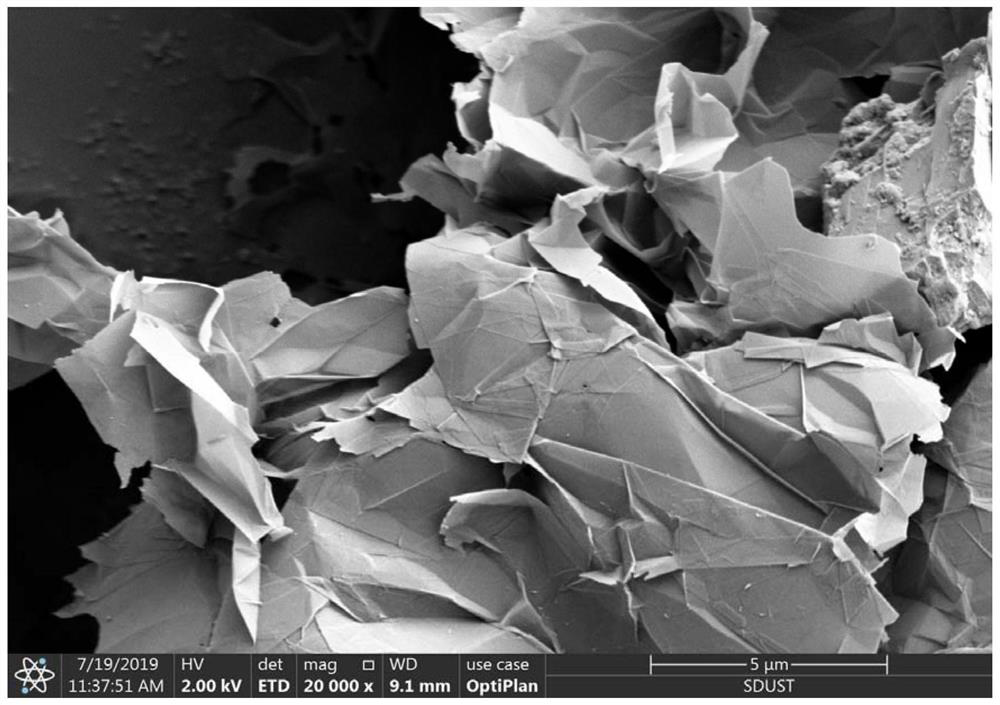

Embodiment 2

[0042] A method for preparing expanded graphite with preferential adsorption properties for aromatic compounds, comprising the following steps:

[0043] 5 g of natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.), add 12 ml of sulfolane and 10 ml of water, shake and mix, add 1 ml of concentrated sulfuric acid, shake and mix, add 0.4 After 1 gram of potassium permanganate was shaken to dissolve and mixed evenly, ultrasonically treated for 5 minutes, and then shaken at room temperature for 1 hour;

[0044] Add hydrogen peroxide dropwise under stirring until the brown color and the purple color of the supernatant disappear, then add 2 ml in excess;

[0045] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and intercalated graphite are transferred to an oven at 105°C for drying;

[0046] The intercalated graphite was transferred to a beaker, and 500 watts of microwave radiati...

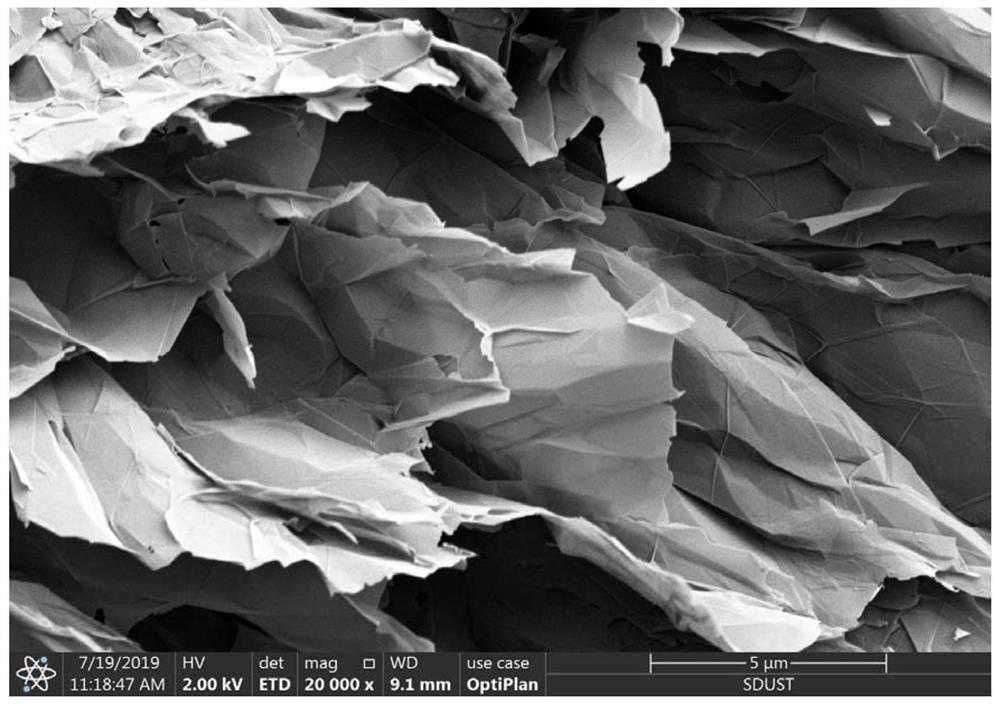

Embodiment 3

[0049]A method for preparing expanded graphite with preferential adsorption properties for aromatic compounds, comprising the following steps:

[0050] Natural flake graphite (80 mesh, 99% carbon content, Qingdao Nanshu Hongda Graphite Products Co., Ltd.) 5 grams, add 10 ml of NMP and 10 ml of water, shake and mix, add 2 ml of concentrated sulfuric acid, shake and mix, add 0.5 After 1 gram of potassium permanganate was shaken to dissolve and mixed evenly, ultrasonically treated for 5 minutes, and then shaken at room temperature for 1 hour;

[0051] Add hydrogen peroxide dropwise under stirring until the brown color and the purple color of the supernatant disappear, then add 2 ml in excess;

[0052] After filtering and washing until the filtrate is nearly neutral (pH test paper test), the filter paper and intercalated graphite are transferred to an oven at 105°C for drying;

[0053] The intercalated graphite is transferred to a beaker, and 500 watts of microwave radiation is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com