An ultrasonic impact forging device

An ultrasonic impact and ultrasonic vibration technology, applied in the field of forging devices, can solve the problems of weakening ultrasonic vibration intensity, affecting the effectiveness of the manufacturing method, and small forging tonnage, so as to improve the stress distribution state, optimize the microstructure of the additive, and ensure the integrity fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

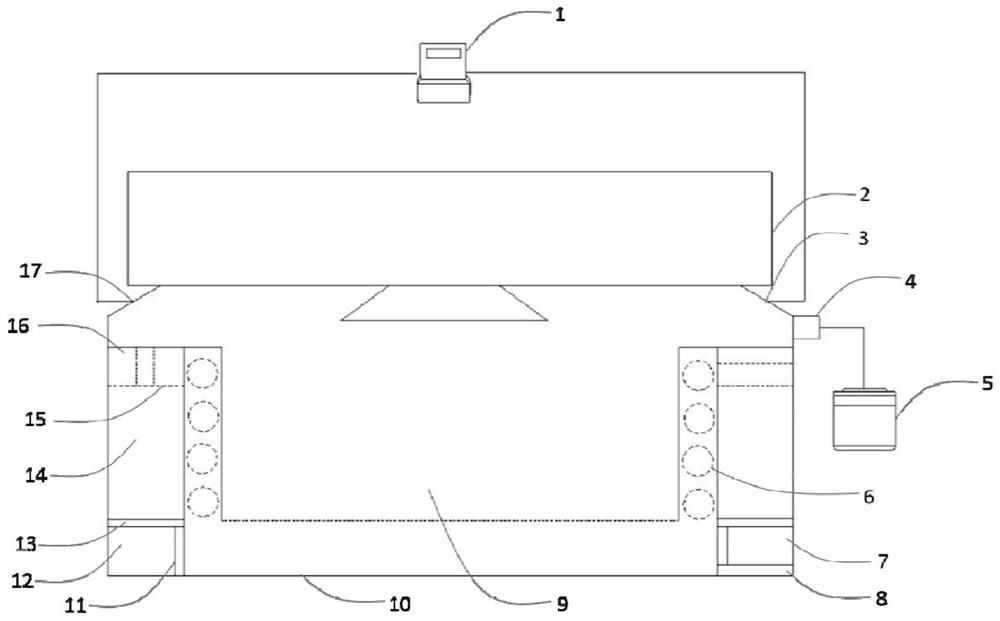

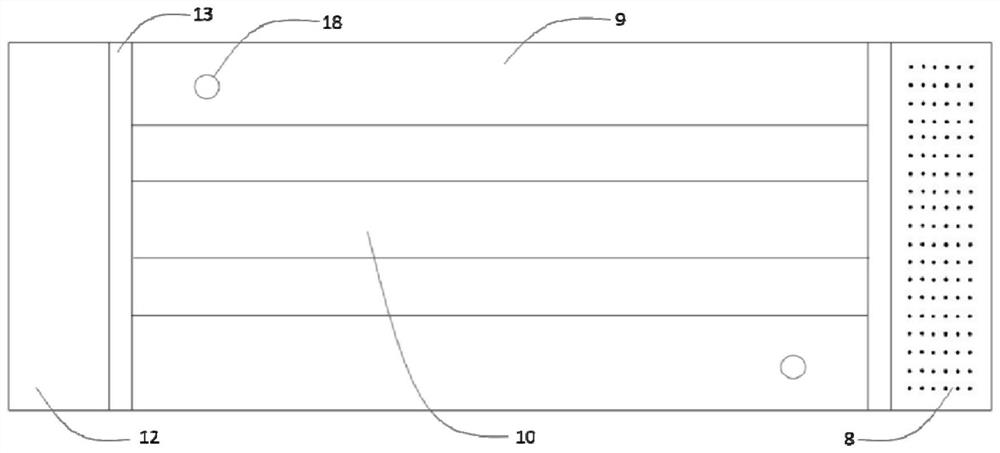

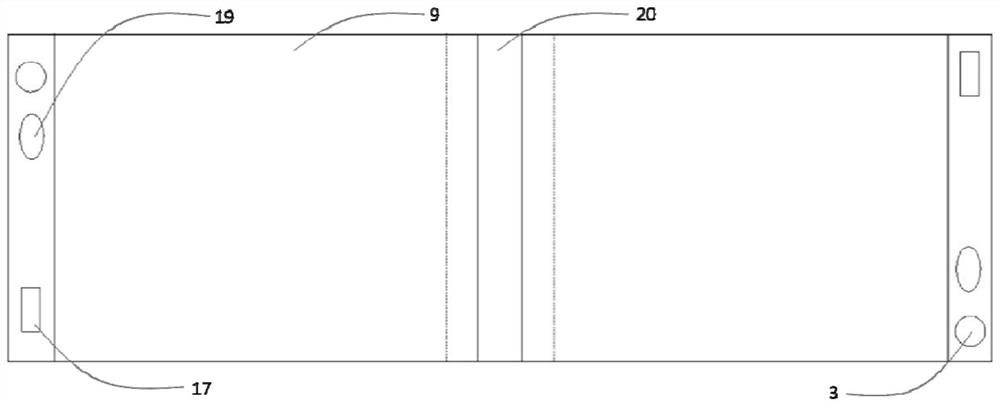

[0027] The present invention will be described in more detail below with reference to the accompanying drawings.

[0028] As an auxiliary equipment for additive manufacturing, the present invention completes the forging of the additive structure in the low-strength state of the alloy, realizes the optimization of the properties of the additive structure and the regulation of internal stress, and achieves the dual functions of trimming the processing surface of the additive structure and removing the oxide layer.

[0029] In order to achieve the purpose of the present invention, the micro-area forging device of the present invention includes a micro-area heating module and a forging module. Micro-area heating module: controller, electric pulse generator, electrode conductor, arc suppression coating, pressure sensor, pressure control box, temperature sensor, resonance sheet, shock absorption sheet, insulating sheet. Forging module: forging body, forging head, water-cooled copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com