Hierarchical pore carbon material and preparation method and application thereof

A technology of graded pore carbon and channels, applied in the field of porous materials, can solve the problems of secondary pollution, severe toxicity, carcinogenicity, etc., and achieve the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the hierarchically porous carbon material described in the above technical solution, comprising the following steps:

[0029] (1) After mixing straw and nanometer calcium carbonate, carry out tabletting treatment, obtain tabletting;

[0030] (2) performing anaerobic pyrolysis on the compressed tablet to obtain a pyrolysis product;

[0031] (3) After mixing and reacting the pyrolysis product with hydrochloric acid, filter and dry in sequence to obtain a hierarchical porous carbon material.

[0032] In the invention, the straw and the nano-calcium carbonate are mixed and then subjected to tableting treatment to obtain compressed tablets. In the present invention, the straw preferably includes one or more of rice straw, tobacco straw, corn straw, wheat straw, millet straw and black soybean straw. In the present invention, the straw is easy to form functional groups, and the straw The particle size is preferably 1...

Embodiment 1

[0045] Weigh 10 g of rice straw with a mesh size of 100 to 300, wash with 500 mL of deionized water, filter, and dry at 80° C. for 12 hours in a blast drying oven. The above product was mixed with 20 g of nano-calcium carbonate (particle size: 20 nm) and put into a ball mill, and ground and dispersed for 1 h at 1500 rpm. And the sample is compressed into tablets by a tablet press, the pressure is 20Mpa, each tablet is 2g, 10 tablets in total. 10 pellets were put into a tube furnace for anaerobic pyrolysis at a nitrogen flow rate of 2 mL / min at a heating rate of 10 °C / min, firstly carbonized at 400 °C for 1 h, and then activated at 800 °C for 2 h. The obtained pyrolysis product was put into 5 mol / L hydrochloric acid solution, stirred with a magnetic stirrer for 6 hours, and then filtered under a vacuum filter, and finally the product was dried in a blast drying oven at 105°C for 24 hours.

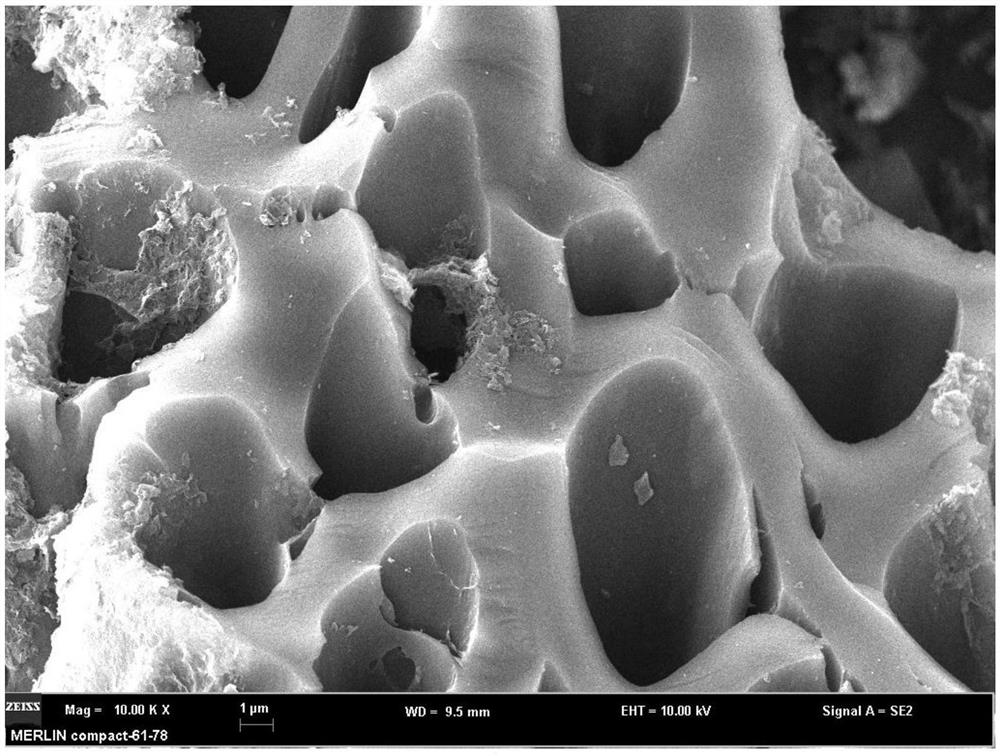

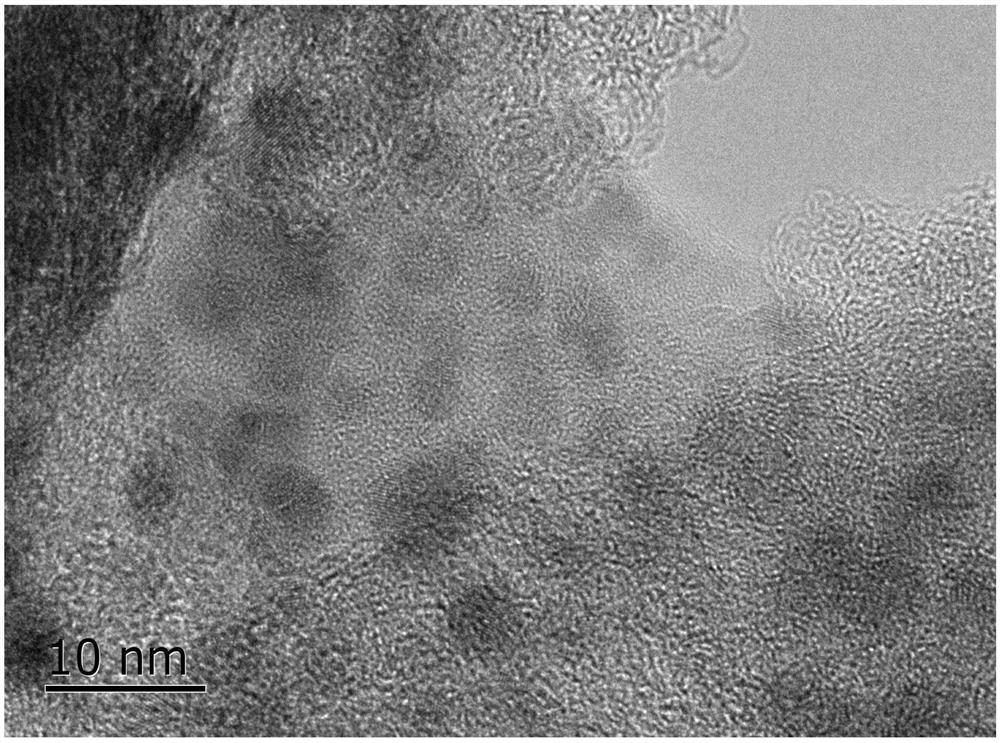

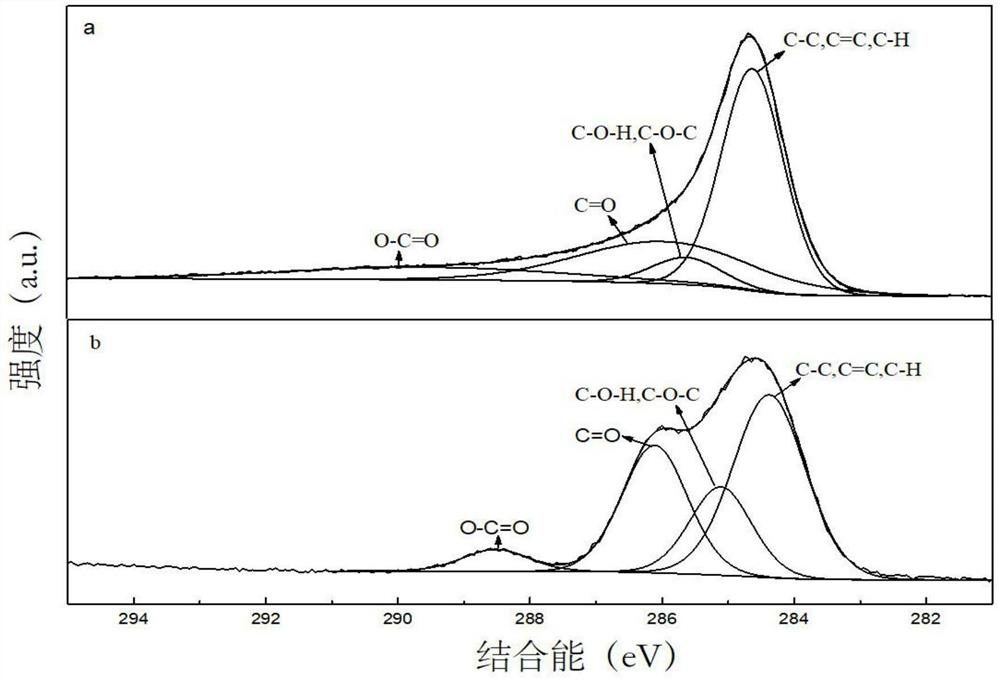

[0046] The hierarchical porous carbon material that embodiment 1 prepares is carried ou...

Embodiment 2

[0057] Weigh 10 g of rice straw with a mesh size of 100-300, wash with 500 mL of deionized water, filter, and dry at 80° C. for 12 h in a blast drying oven. The above product was mixed with 10 g of nano-calcium carbonate (particle size: 20 nm), then put into a ball mill, and ground and dispersed for 1 h at 1500 rpm. And the sample is compressed into tablets by a tablet press, the pressure is 20Mpa, each tablet is 2g, 10 tablets in total. 10 pellets were put into a tube furnace for anaerobic pyrolysis at a nitrogen flow rate of 2 mL / min at a heating rate of 10 °C / min, firstly carbonized at 400 °C for 1 h, and then activated at 800 °C for 2 h. The obtained pyrolysis product was put into 5 mol / L hydrochloric acid solution, stirred with a magnetic stirrer for 6 hours, and then filtered under a vacuum filter, and finally the product was dried in a blast drying oven at 105°C for 24 hours.

[0058] Scanning electron microscope analysis and transmission electron microscope analysis w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com