Al2O3-B2O3-SiO2 composite sol, core-shell structure activated carbon fiber and preparation method thereof

A technology of activated carbon fiber and composite sol, applied in the field of activated carbon fiber, can solve the problem of low inherent strength of activated carbon fiber, and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

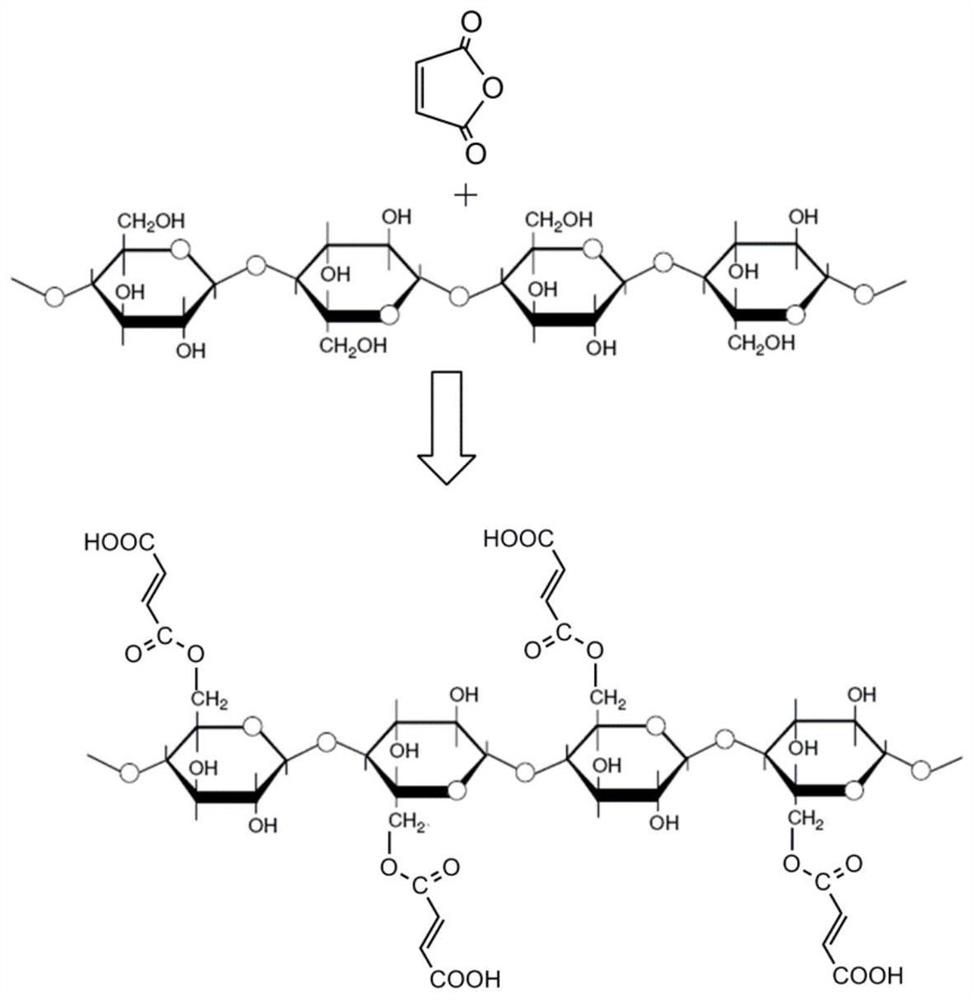

[0039] The preparation material of core-shell structure activated carbon fiber provided by the invention comprises: regenerated cellulose rayon, surface modification molecule maleic anhydride and Al 2 o 3 -B 2 o 3 -SiO 2 Composite sol mixture.

[0040] In the prior art, both maleic anhydride and polycarboxylic acid are used to modify the surface of cellulose fibers, mainly to anchor dye molecules. In this application, a maleic anhydride-modified surface was used to anchor Al 2 o 3 -B 2 o 3 -SiO 2 sol mixture shell, thus forming Al 2 o 3 -B 2 o 3 -SiO 2 The core-shell structure activated carbon fiber of composite oxide ceramic shell layer 1.

[0041] Raw materials of regenerated cellulose man-made fibers include: Lyocell fiber (textile industry standard FZ / T52019-2011), modal fiber (textile industry standard FZ / T 52043-2016), bamboo viscose fiber (textile industry standard FZ / T52043-2016), bamboo viscose fiber (textile industry standard Standard FZ / T 52006-2006),...

Embodiment 1

[0067] The invention provides a method for preparing activated carbon fibers with a core-shell structure, comprising the steps of:

[0068] Step 1. 10 g of regenerated cellulose fiber raw material is impregnated with an acetone solution with a mass concentration of maleic anhydride of 3%, so that the loading of maleic anhydride is 1.5% of the mass of the regenerated cellulose man-made fiber. Afterwards, the fiber raw material adsorbed maleic anhydride was heated to 80° C. for 60 minutes. The purpose of heat treatment was to accelerate the esterification reaction between maleic anhydride and hydroxyl groups on the fiber surface.

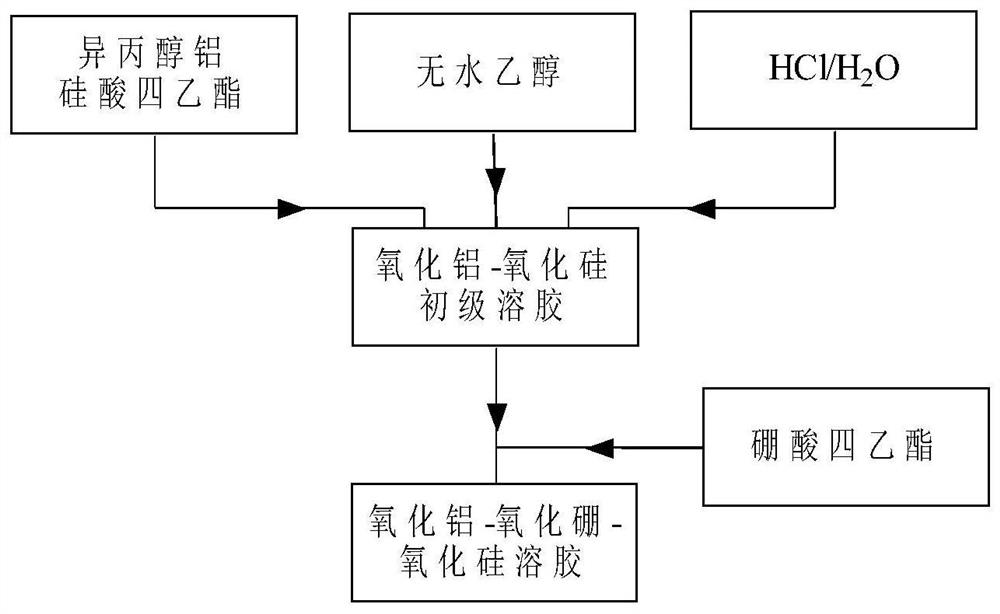

[0069] Step 2. Mix 12.25g (0.06mol) aluminum isopropoxide and 6.25g (0.03mol) tetraethyl silicate with 15.2g absolute ethanol evenly. Then add HCl (0.04g, 1.1mmol) / H 2 O (4.36g, 0.242mol), the mixture was stirred at room temperature for 20min to form an alumina-silica primary sol, then 2.92g (0.02mol) triethyl borate was added, and the mixture was he...

Embodiment 2

[0076] The invention provides a method for preparing activated carbon fibers with a core-shell structure, which is used to study Al 2 o 3 -B 2 o 3 -SiO 2 The influence of the aluminum-boron-silicon element ratio (as shown in Table 2) on the mechanical properties of the final core-shell structure activated carbon fiber in the composite sol specifically includes the following steps:

[0077] Step 1. 10 g of Lyocell fiber raw materials are impregnated with an acetone solution with a mass concentration of maleic anhydride of 3%, so that the loading of maleic anhydride is 1.5% of the mass of the regenerated cellulose rayon. Afterwards, the fiber raw material adsorbed maleic anhydride was heated to 80° C. for 60 minutes. The purpose of heat treatment was to accelerate the esterification reaction between maleic anhydride and hydroxyl groups on the fiber surface.

[0078] Step 2. Use Al 2 o 3 -B 2 o 3 -SiO 2 The total molar amount of the precursor raw materials composed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com