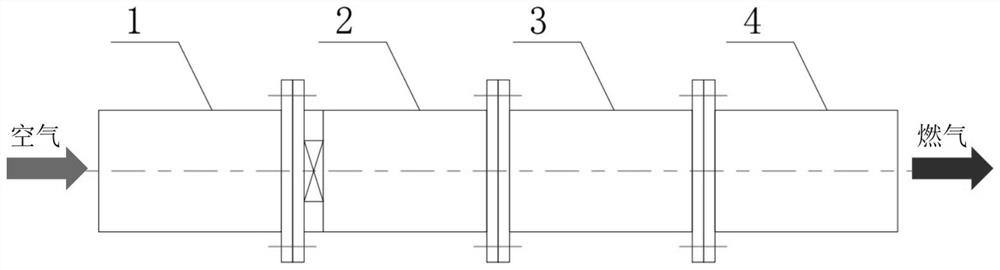

Displacement temperature measuring device suitable for high-temperature and high-pressure rectangular test piece

A high-temperature, high-pressure, temperature-measuring device technology, applied in the direction of measuring devices, machine/structural component testing, engine testing, etc., can solve problems such as difficulty in measuring outlet temperature, achieve small size, small flow field interference, and improve measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

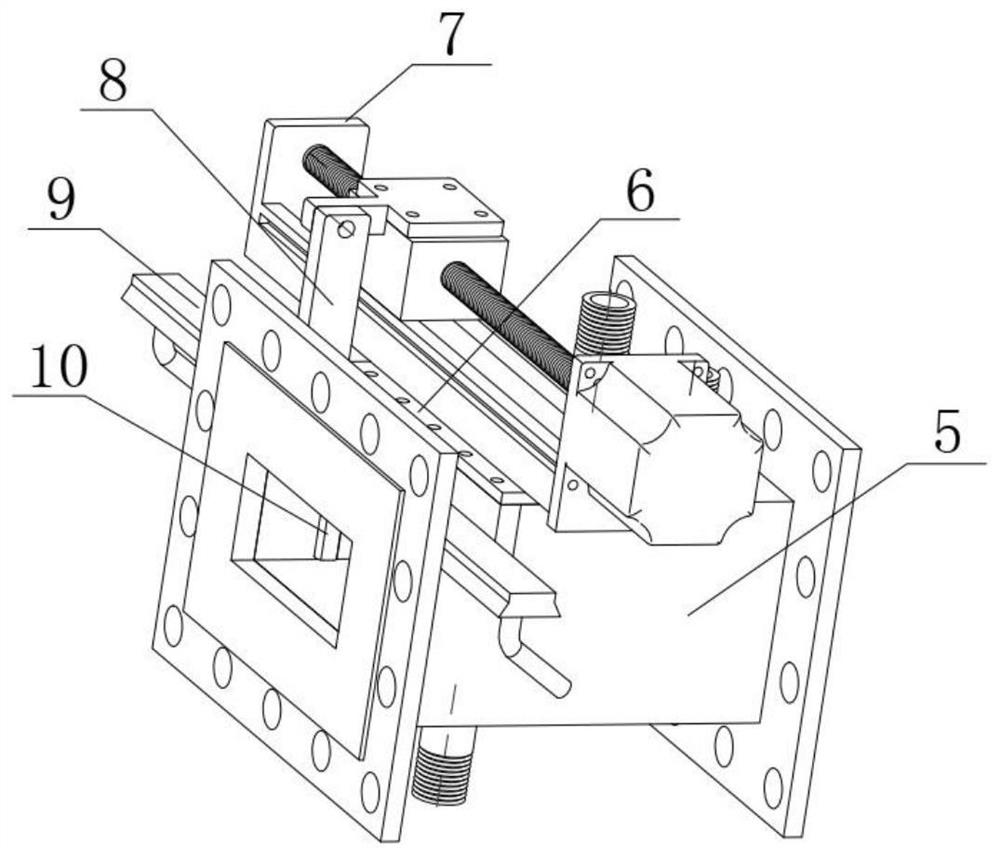

[0032] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

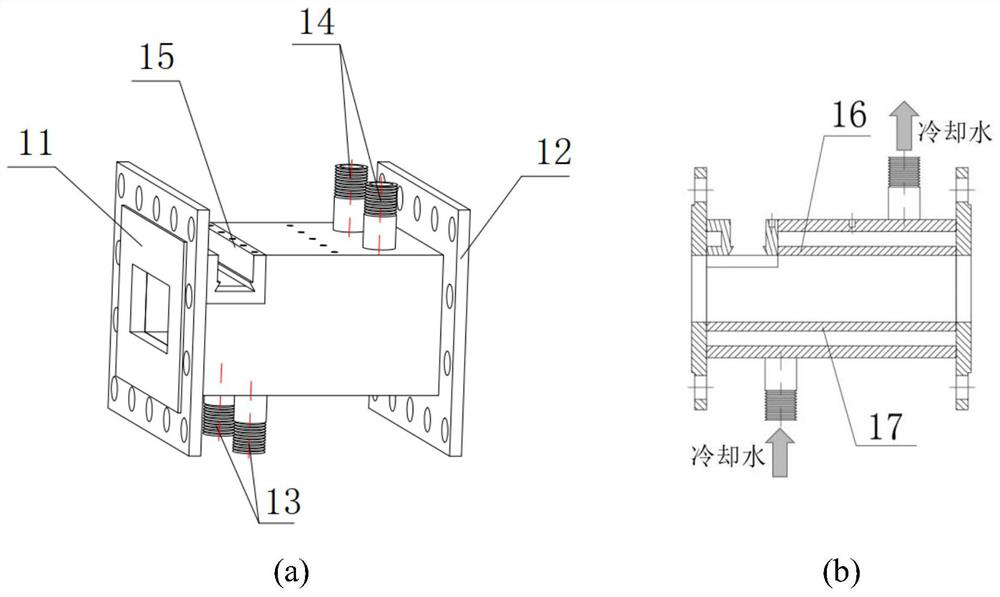

[0033]A displacement temperature measuring device suitable for high-temperature and high-pressure rectangular test pieces proposed by the present invention mainly consists of a water-cooled measuring section cavity 5, a displacement mechanism mounting seat 6, a displacement mechanism 7, a displacement rod 8, an air-cooled The sealing strip 9 and the multi-point temperature measurement rake 10 are composed. The cavity 5 of the water-cooled measurement section is welded by the front flange 11 of the water-cooled measurement section, the rear flange 12 of the water-cooled measurement section, the dovetail groove base 15, the inner wall 16 of the water-cooled measurement section and the outer wall 17 of the water-cooled measurement section. The water inlet joint 13 and the water outlet joint 14 are respectively welded on the outer wall 17 of the water-cooled measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com