A dual-temperature air-conditioning system, control method, and air conditioner

An air-conditioning system and exhaust temperature technology, applied in air-conditioning systems, refrigeration and liquefaction, space heating and ventilation, etc., can solve the problems that throttling devices cannot achieve stable control, and the system cannot operate stably, reliably, and efficiently. The effect of reliable and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

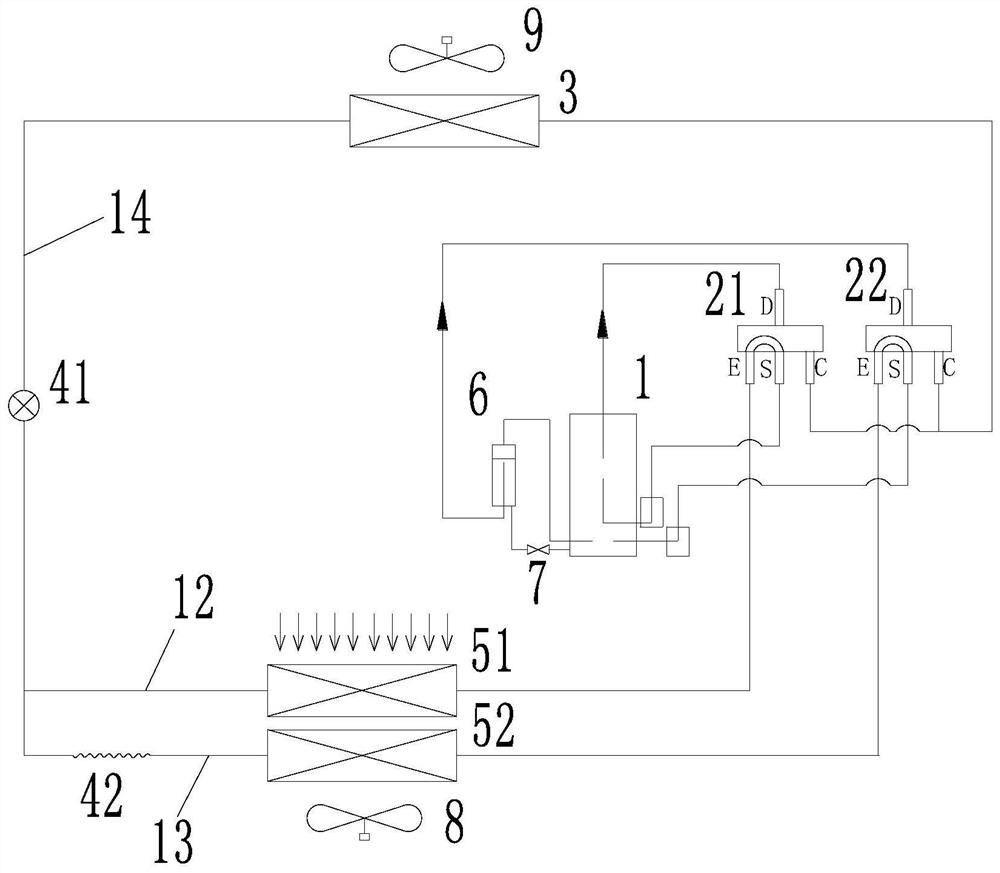

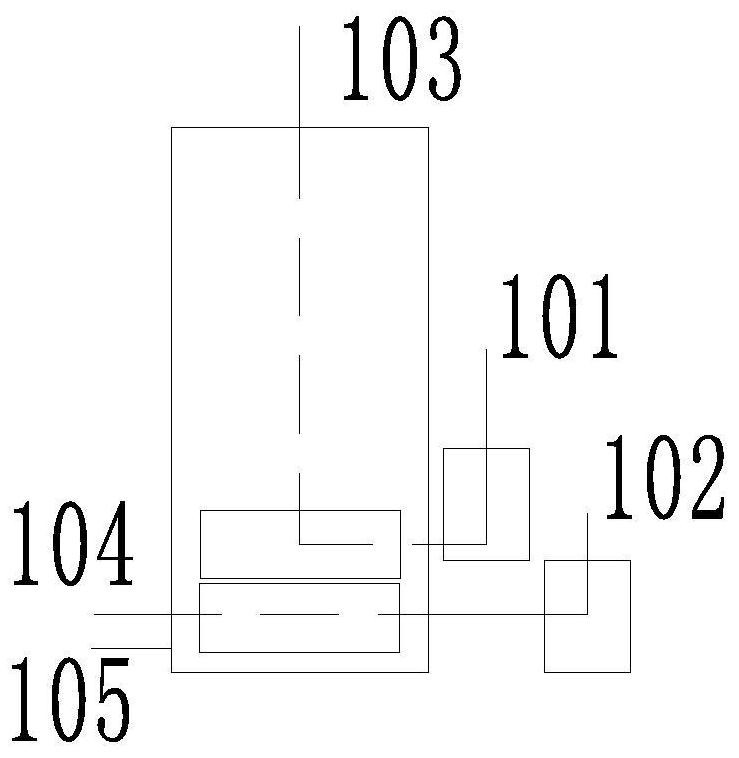

[0087] A dual-temperature system, including a double-suction double-row compressor 1, an oil separator 6, an oil return control valve 7, a first four-way valve 21 and a second four-way valve 22, an outdoor heat exchanger 3, and a first throttle device 41 and second throttling device 42 , first indoor heat exchanger 51 and second indoor heat exchanger 52 , outdoor fan 9 and indoor fan 8 . The double-suction double-row compressor has a first suction port 101 and a first discharge port 103 connected to the first compression cylinder, and a second suction port 102 and a second discharge port connected to the second compression cylinder 104, and the oil return port 105 that communicates with the oil sump at the bottom of the compressor.

[0088] The first exhaust port 103 is connected to the outdoor heat exchanger 3 through the first four-way valve 21, the second exhaust port 104 is connected to the oil separator 6, and the oil separator 6 is connected to the outdoor heat exchanger...

Embodiment 2

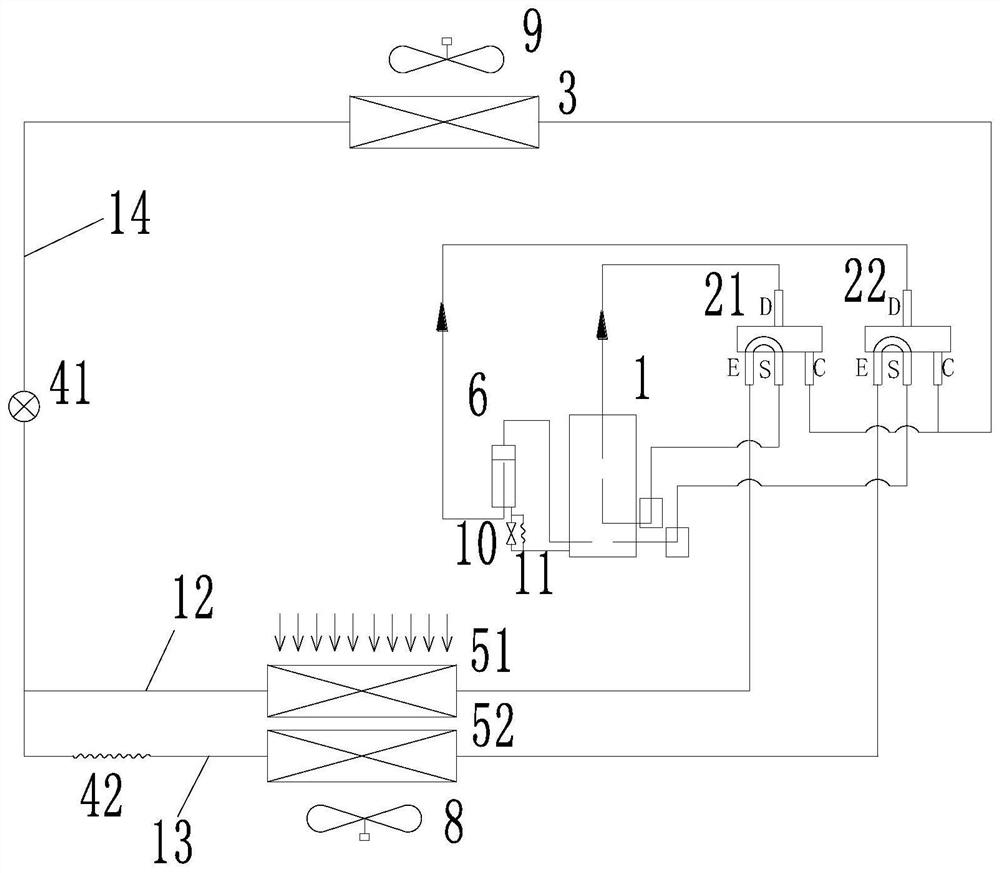

[0090] An air conditioning system, comprising a double-suction double-row compressor 1, an oil separator 6, an oil return stop valve 10, an oil return capillary 11, a first four-way valve 21 and a second four-way valve 22, an outdoor heat exchanger 3, The first throttling device 41 and the second throttling device 42 , the first indoor heat exchanger 51 and the second indoor heat exchanger 52 , the outdoor fan 9 and the indoor fan 8 . The double-suction double-row compressor has a first suction port 101 and a first discharge port 103 connected to the first compression cylinder, and a second suction port 102 and a second discharge port connected to the second compression cylinder 104, and the oil return port 105 that communicates with the oil sump at the bottom of the compressor.

Embodiment 3

[0092] Embodiment 3 is basically the same as Embodiment 1 or 2, the difference is that in this embodiment, the oil return device is omitted, and the gas discharged from the first cylinder and the gas discharged from the second cylinder are compressed The mixture inside the shell of the machine is discharged through the third exhaust port 106, and the third exhaust port 106 is respectively connected to a port of the first four-way valve 21 and the second four-way valve 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com