Oxidized tail gas energy recovery method during cyclohexanone oxidation production

A technology of oxidizing tail gas and energy recovery device, which is applied in the direction of combustion methods, incinerators, gas turbine devices, etc., can solve problems such as corrosion of expander operation, unreasonable energy utilization, and excessive organic matter in tail gas, and achieve stable operation and reduce low-pressure steam Consumption, high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment is a method for energy recovery of oxidation tail gas in the production of cyclohexanone by oxidation method, and the technical process of the method specifically includes:

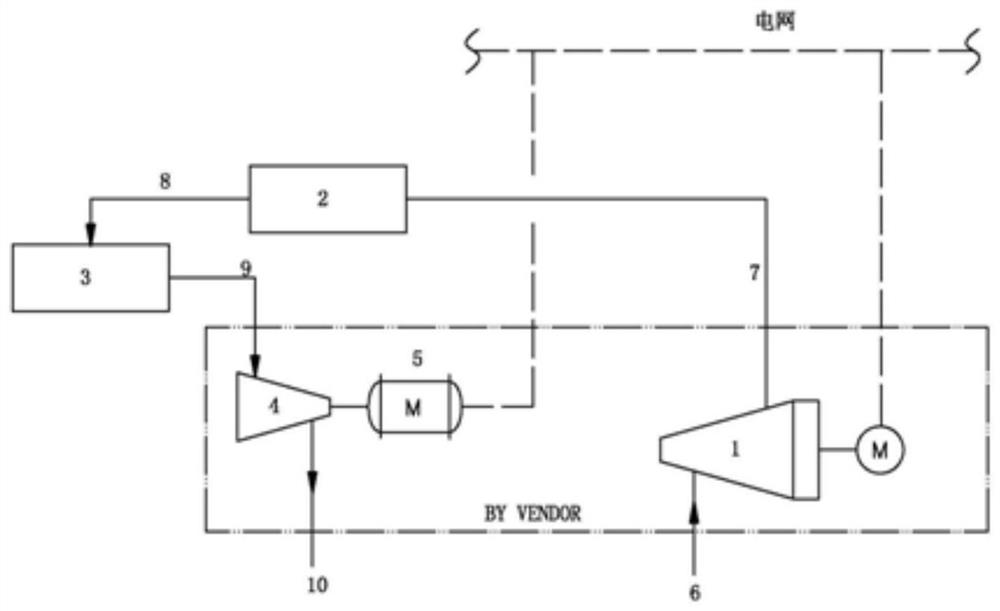

[0039] like figure 1 As shown, the normal temperature and pressure air 6 is pressurized by the air compressor 1 and the pressurized air 7 enters the oxidation unit 2 to participate in the reaction, and the reacted oxidation tail gas 8 is passed into the catalytic combustion unit 3, and the high temperature and high pressure tail gas 9 produced is sent into the oxidation unit 2 to participate in the reaction. The air expander 4 expands to perform work, converts heat energy into mechanical energy, and then drives the generator 5 to generate electricity, and the electric energy generated by the generator 5 is incorporated into the grid. And the exhaust gas 10 of the air expander 4 is directly discharged into the atmosphere.

[0040] In this embodiment, the organic matter in the oxidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com