Fire-resistant composite floor slab and fire-resistant performance test method thereof

A combined floor, fire and weather resistance technology, applied in the direction of floor, fire protection, building components, etc., to achieve the effect of reducing the deformation range, simplifying the painting, saving maintenance costs and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

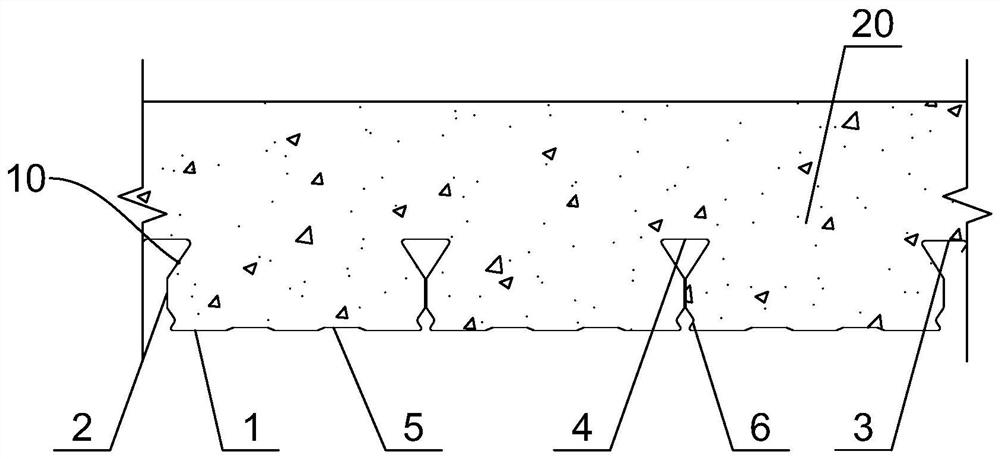

[0032] Such as figure 1As shown, the fire-resistant composite floor slab of this embodiment includes a refractory steel profiled floor deck 10 and concrete 20, the profiled floor deck 10 includes a rib 4 with a closed hollow, and the profiled floor deck 10 The concrete 20 is poured on the profiled floor bearing slab 10, and the upper surface of the concrete 20 is leveled after pouring and cured, and the profiled floor bearing The boards 10 are combined into one and used as a fire-resistant composite floor as a whole; the profiled floor deck 10 is made of fire-resistant steel through integral rolling forming, including the bottom plate 1 and the first fastening parts respectively located at the left and right ends of the bottom plate 1 2 and the second fastening part 3, several ribs 4 arranged at intervals in the middle of the bottom plate 1, the first fastening part 2 of the adjacent profiled floor deck 10 and the first fastening part 2 The two fastening parts 3 are matched a...

Embodiment 2

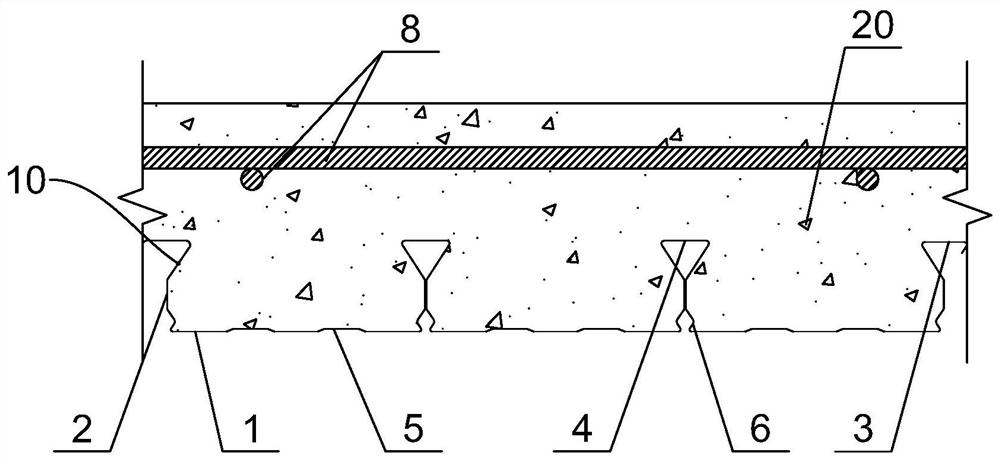

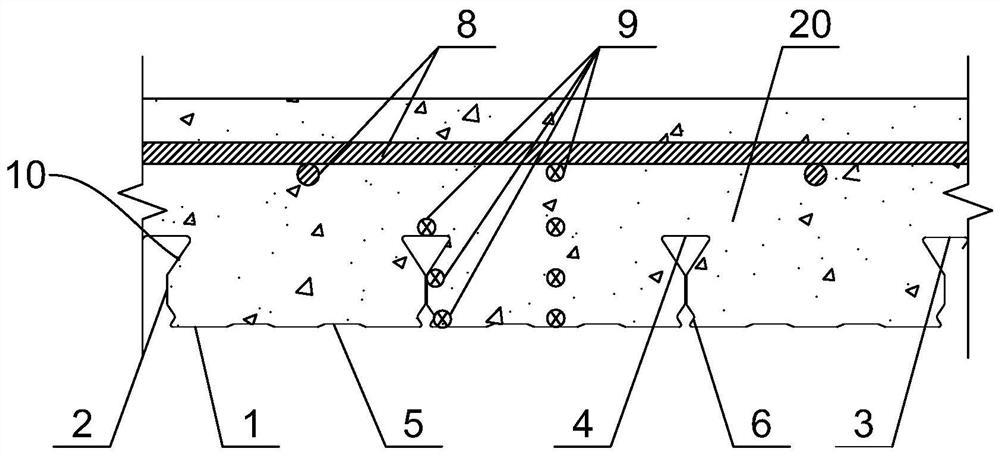

[0063] Such as figure 2 , image 3 As shown, the difference between the fire-resistant composite floor slab of this embodiment and Embodiment 1 is that in this embodiment, the fire-resistant composite floor slab also includes a crack-resistant steel mesh 8, and the crack-resistant steel mesh 8 adopts steel bars for building structures or fire-resistant Steel reinforcement or refractory and weather-resistant steel reinforcement is formed by cross spot welding, and the crack-resistant steel mesh 8 is erected on the compression zone of the concrete 20 above the profiled floor deck 10, and after pouring the concrete 20 and the The concrete 20 is combined into one body, and the thickness of the concrete 20 above the crack-resistant steel mesh 8 is not less than 20 mm, so as to protect the crack-resistant steel mesh 8 and ensure that it does not fall off and does not come into contact with the outside world and be damaged. corrosion.

[0064]In the actual fire situation, in the t...

Embodiment 3

[0067] Such as Figure 4 As shown, the difference between the fire-resistant composite floor slab of this embodiment and the first embodiment is that the profiled floor deck 10 of this embodiment is a fire-resistant and weather-resistant steel profiled floor deck, and the profiled floor deck 10 is made of fire-resistant and weather-resistant steel Manufactured by integral roll forming, the cross section of the wedge-shaped part of the rib 4 is a regular hexagon, and the first fastening part 2 of the adjacent profiled floor deck 10 and the second After the two fastening parts 3 are fastened and connected, the overall shape of the fastened part is also a regular hexagon, which can further increase the contact area between the profiled rib 4 and the concrete 20, and the profiled floor deck 10 The ability to combine with the concrete 20 is enhanced, and the profiled floor deck 10 is protected by the concrete 20 and will not fall off, preventing it from losing its structural functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com