High-toughness corrosion-resistant aluminum alloy and heat treatment method thereof

A technology of corrosion-resistant aluminum alloy and high toughness, which is applied in the field of high-toughness corrosion-resistant aluminum alloy and its heat treatment method. It can solve the problems of single casting method, low crack tendency, and difficult casting, and achieve the improvement of oxide film characteristics and crack tendency. low resistance, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Put all the metal aluminum ingots into a smelting furnace for smelting at a melting temperature of 750°C until they are completely melted to form an aluminum melt;

[0025] (2) Gradually add 2.8% Si, 0.25% Fe, 0.7% Mn, 0.25% Zn, 0.15% Ti, 0.15% Zr, 0.01% V to obtain aluminum alloy melt during heating;

[0026] (3) Stir the aluminum alloy melt at a temperature of 740°C for 10 minutes, add a special refining agent for aluminum alloys during the stirring process for refining and degassing; after refining, remove the flux and scum on the liquid surface, and let it stand for about 15min;

[0027] (4) Keep the melt temperature at 710°C, add 6.5% Mg, 50ppmBe, let stand for 15 minutes, and stir for 20 minutes after standing;

[0028] (5) Keep the aluminum alloy melt at 700°C for high-pressure die-casting to obtain the finished product;

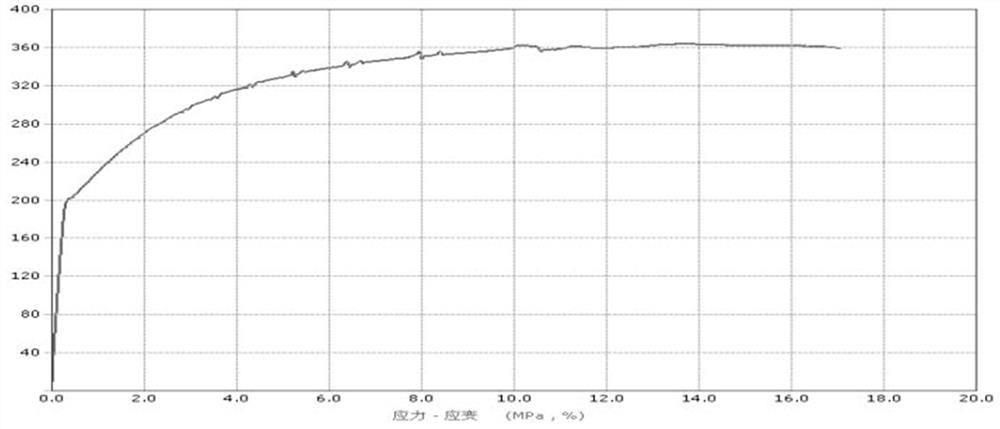

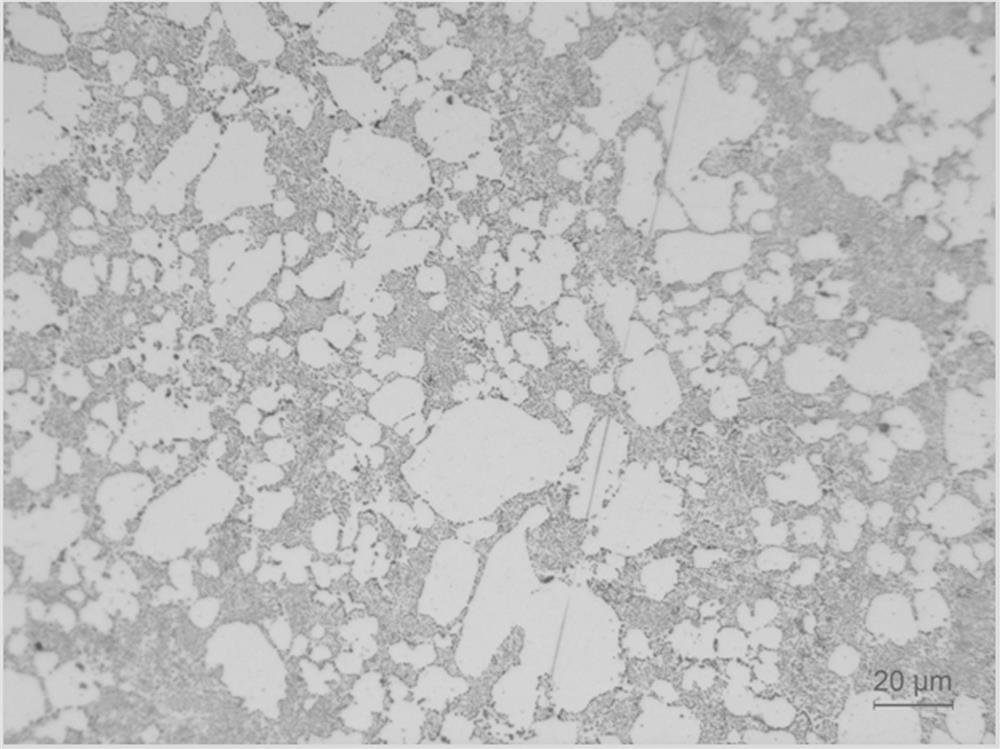

[0029] The resulting finished product has not been heat-treated, and the tensile strength of the material is 363Mpa, the yield strength ...

Embodiment 2

[0031] (1) Put all the metal aluminum ingots into a smelting furnace for smelting at a melting temperature of 740°C until they are completely melted to form an aluminum melt;

[0032] (2) Gradually add 2.4% Si, 0.20% Fe, 0.5% Mn, 0.20% Zn, 0.11% Ti, 0.11% Zr, 0.015% V to obtain aluminum alloy melt during heating;

[0033] (3) Stir the aluminum alloy melt at a temperature of 750°C for 10 minutes. During the stirring process, add a special refining agent for aluminum alloys for refining and degassing; after refining, remove the flux and scum on the liquid surface, and let it stand for about 10min;

[0034] (4) Keep the melt temperature at 720°C, add 6.0% Mg, 45ppmBe, let stand for 15 minutes, and stir for 15 minutes after standing;

[0035] (5) Keep the aluminum alloy melt at 690°C and perform high-pressure die-casting to obtain the finished product;

[0036] (6) Carry out heat treatment to the obtained finished product, raise the temperature of the heat treatment furnace to 1...

Embodiment 3

[0039] (1) Put all the metal aluminum ingots into a smelting furnace for smelting at a melting temperature of 735°C until they are completely melted to form an aluminum melt;

[0040] (2) Gradually add 3.0% Si, 0.27% Fe, 0.75% Mn, 0.30% Zn, 0.18% Ti, 0.14% Zr, 0.025% V to obtain aluminum alloy melt during heating;

[0041] (3) Stir the aluminum alloy melt at a temperature of 720°C for 10 minutes. During the stirring process, add a special refining agent for aluminum alloys for refining and degassing; after refining, remove the flux and scum on the liquid surface, and let it stand for about 10min;

[0042] (4) Keep the melt temperature at 725°C, add 6.8% Mg, 55ppmBe, let stand for 20 minutes, and stir for 30 minutes after standing;

[0043] (5) Keep the aluminum alloy melt at 700°C for high-pressure die-casting to obtain the finished product;

[0044] (6) Carry out heat treatment to the obtained finished product, raise the temperature of the heat treatment furnace to 195° C.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com