High-chlorine desulfurized gypsum plaster board and method for improving bonding grade of high-chlorine desulfurized gypsum plaster board by activating zeolite

A technology of paper-faced gypsum board and desulfurization gypsum, applied in the field of high-chlorine desulfurization gypsum paper-faced gypsum board, can solve the problems of poor dehydration and poor adhesion of the paper-faced gypsum board, and achieve the effect of good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

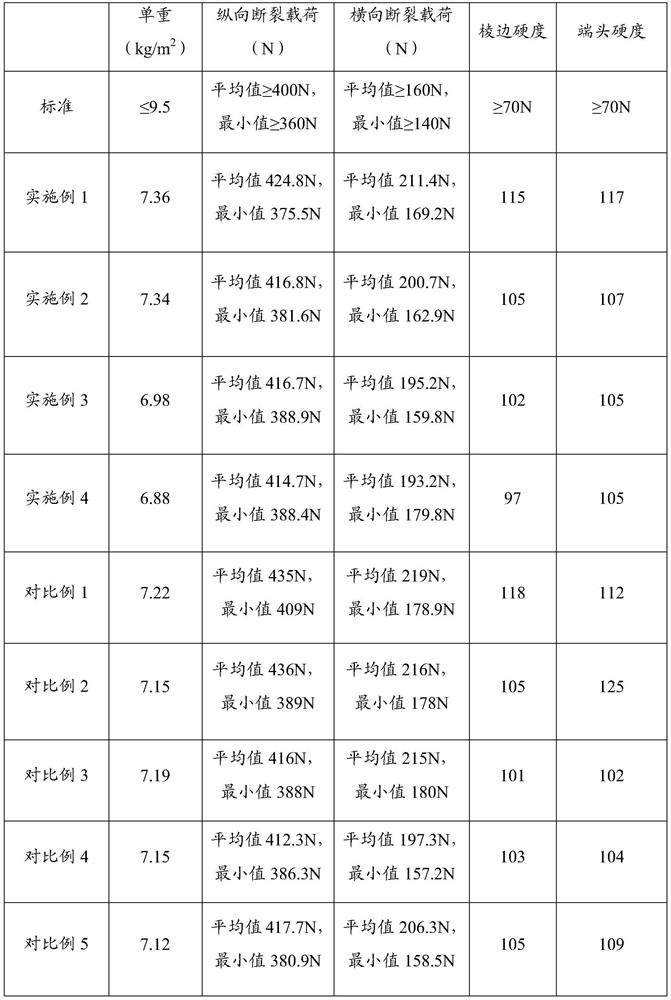

Examples

Embodiment 1

[0043] The gypsum board prepared in this example has a chloride ion content of 1389 mg / kg in the raw material desulfurized gypsum clinker.

[0044] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0045] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0046] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.06 parts by weight of medium-alkali glass fiber (the length of glass fiber is 9 mm, and the diameter of fiber filament is 10 μm), stir mechanically, and mix evenly to prepare a mixture.

[0047] Step 3: Weigh 60 parts by weight of water, 1.2 parts by weight of pretreated zeolite, 0.8 part...

Embodiment 2

[0053] The paper surface gypsum board prepared in this embodiment has a chloride ion content of 1564 mg / kg in the raw material desulfurized gypsum clinker.

[0054] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0055] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0056] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.18 parts by weight of non-alkali glass fiber (the length of the glass fiber is 15 mm, and the diameter of the fiber monofilament is 15 μm), stir mechanically, and mix evenly to prepare a mixture.

[0057] Step 3: Weigh 65 parts by weight of water, 4.2 parts by weight of p...

Embodiment 3

[0060] The paper-faced gypsum board prepared in this embodiment has a chloride ion content of 4820 mg / kg in the raw material desulfurized gypsum clinker.

[0061] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0062] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0063] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.1 part by weight of alkali-resistant glass fiber (the length of glass fiber is 12 mm, and the diameter of fiber monofilament is 12 μm), stir mechanically, and mix evenly to prepare a mixture.

[0064] Step 3: Weigh 72 parts by weight of water, 6.8 parts by weight of pretrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com