Gypsum-based self-leveling floor material and preparation method thereof

A gypsum-based, leveling technology, applied in the field of new building materials, can solve the problems of decorative and intelligent functional mortars that are rarely reported, and achieve the effects of improving the temperature and humidity environment, good fluidity, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

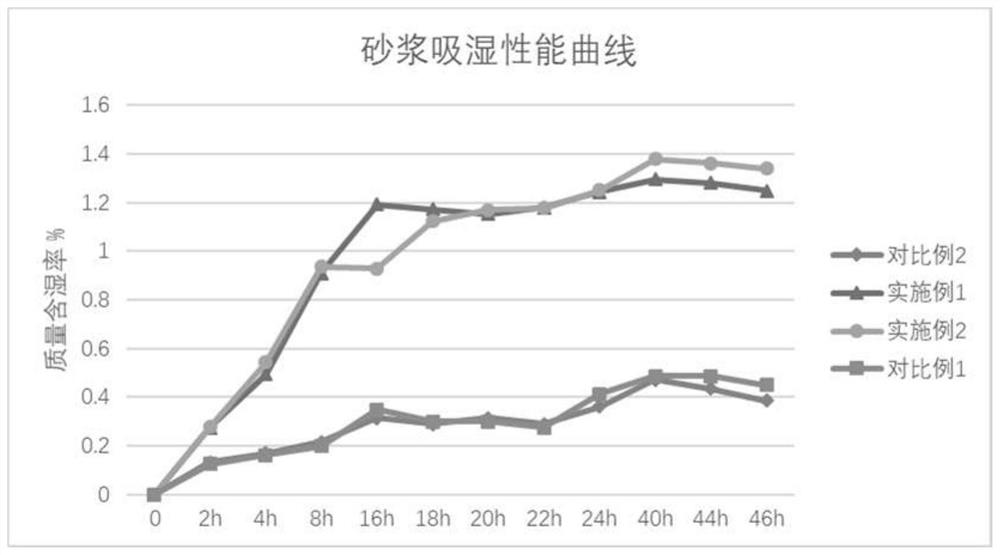

Examples

Embodiment 1

[0045] The preparation of gypsum-based self-leveling floor materials is as follows:

[0046] Step 1: Preparation of phase change energy storage and heat storage materials. For the preparation method, please refer to the literature: Preparation and Characterization of Paraffin Microcapsule Phase Change Materials [J]. Huang Xiaohong, Ji Zhen, etc., Powder Metallurgy Technology, 2015, 33(5). Weigh 5 parts by weight of the phase-change energy storage heat storage material for subsequent use

[0047] Step 2: Grind the color-changing silica gel, pass through a 200-mesh sieve, and weigh 5 parts by weight for later use;

[0048] Step 3: Mix 20 parts by weight of the desulfurized gypsum clinker with the low-temperature phase-change energy storage and heat storage material prepared in step 1 and set aside;

[0049] Step 4: The premix obtained in step 3 is divided into 80 parts by weight of desulfurized gypsum clinker, 5 parts by weight of discolored silica gel powder in step 2, and 2 ...

Embodiment 2

[0061] The method for preparing the gypsum-based self-leveling floor material is the same as in Example 1, except that:

[0062] Anhydrite (purchased from Nanjing Special Non-metallic Materials Co., Ltd.) is 100 parts by weight, Portland cement is 5 parts by weight, K 2 SO 4 2 parts by weight, the water reducer is 0.2 parts by weight of polycarboxylate water reducer, the redispersible latex powder is 3 parts by weight, the water retaining agent is 0.05 parts by weight, and the filler is 50 parts by weight (70-90 mesh). Test the standard consistency water consumption of the above mortar, prepare slurry according to the standard consistency water consumption, and lay it with a laying thickness of 5mm.

[0063] The gypsum-based self-leveling mortar produced in Example 2 is subjected to a performance test according to the test method described in Example 1, and the results are shown in Table 2 below:

[0064] Table 2

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com