Tool setting method of mechanical arm feeding type laser etching system

A laser etching, robotic arm technology, used in laser welding equipment, image data processing, complex mathematical operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

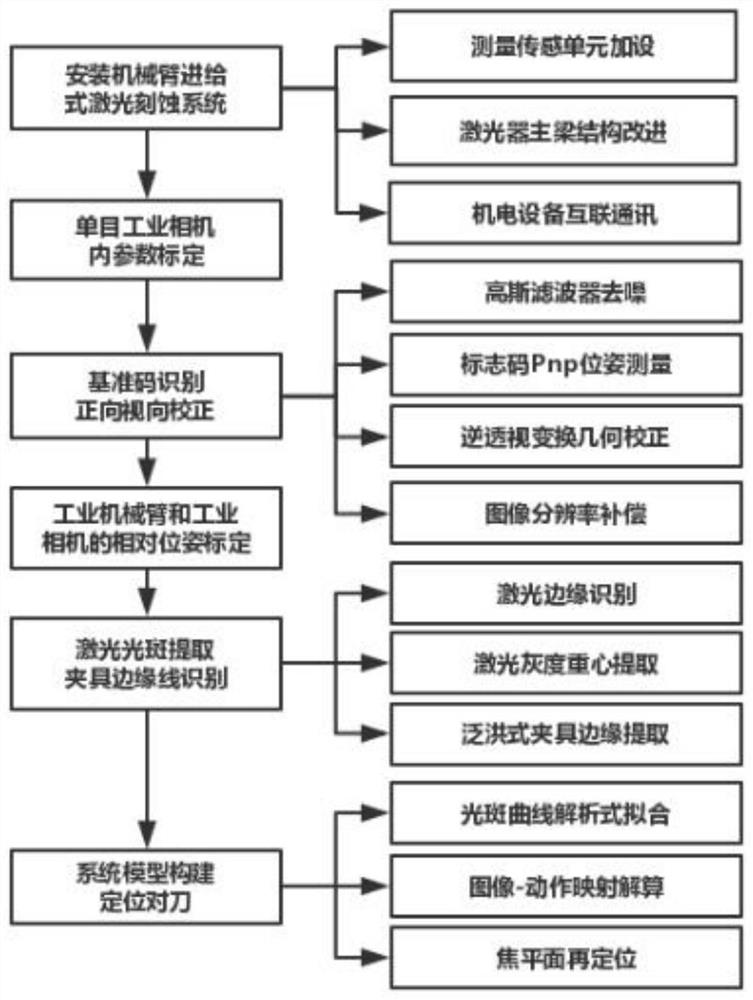

[0111] In order to make the present invention convenient for engineering application, the system configuration and usage method involved in the present invention will be clearly and completely described below in conjunction with the embodiments and accompanying drawings provided by the present invention:

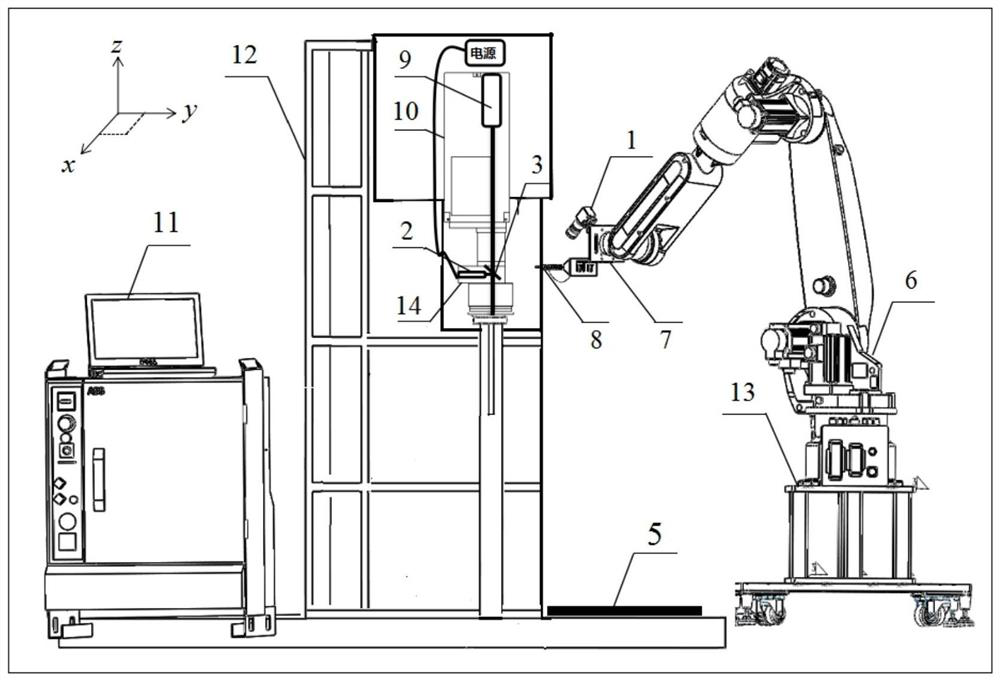

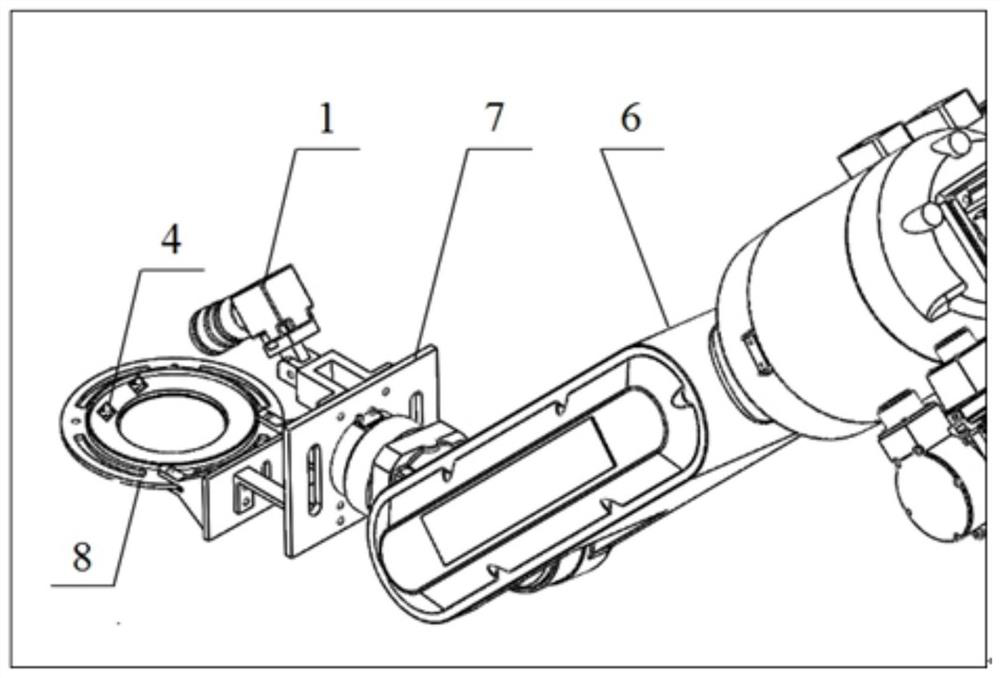

[0112] attached figure 1 and attached figure 2 Shown is the general structure diagram of the robotic arm feeding laser etching system and the close-up view of the hand range of the industrial robotic arm, in which the monocular industrial camera 1, the red indicator laser 2, the beam combiner 3, and the ArUco square reference code 4 , The checkerboard calibration plate 5 constitutes a positioning tool setting device.

[0113] In the embodiment of the invention: the industrial mechanical arm 6 is a medium and light-load six-axis series industrial mechanical arm with a load capacity of 20kg; the red indicator laser 2 is a semiconductor continuous laser driven by electric exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com