A diamond automatic welding frame

An automatic welding and diamond technology, applied in welding equipment, metal processing, metal processing equipment, etc., can solve the problems of transmission error, uncontrollable bending failure rate, burr scratching of the cutter head, etc., so as to reduce the failure rate and avoid human visual inspection Deviation, the effect of preventing mutual rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

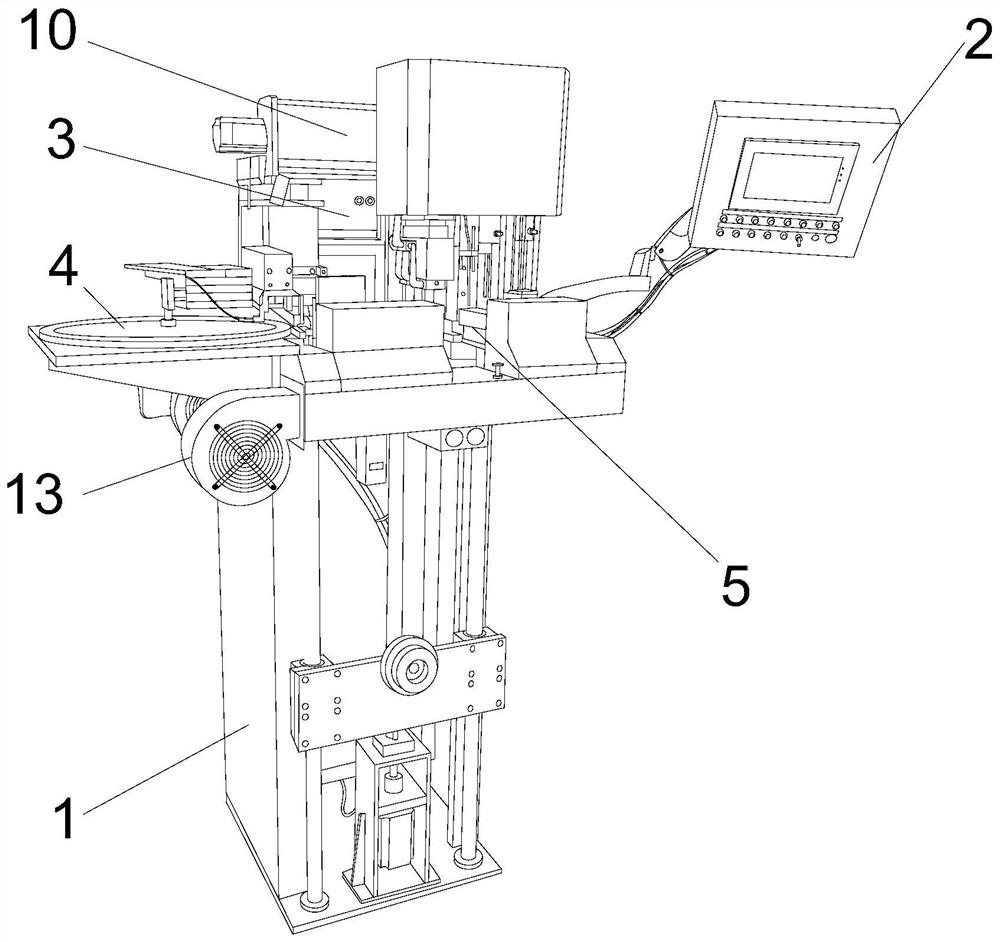

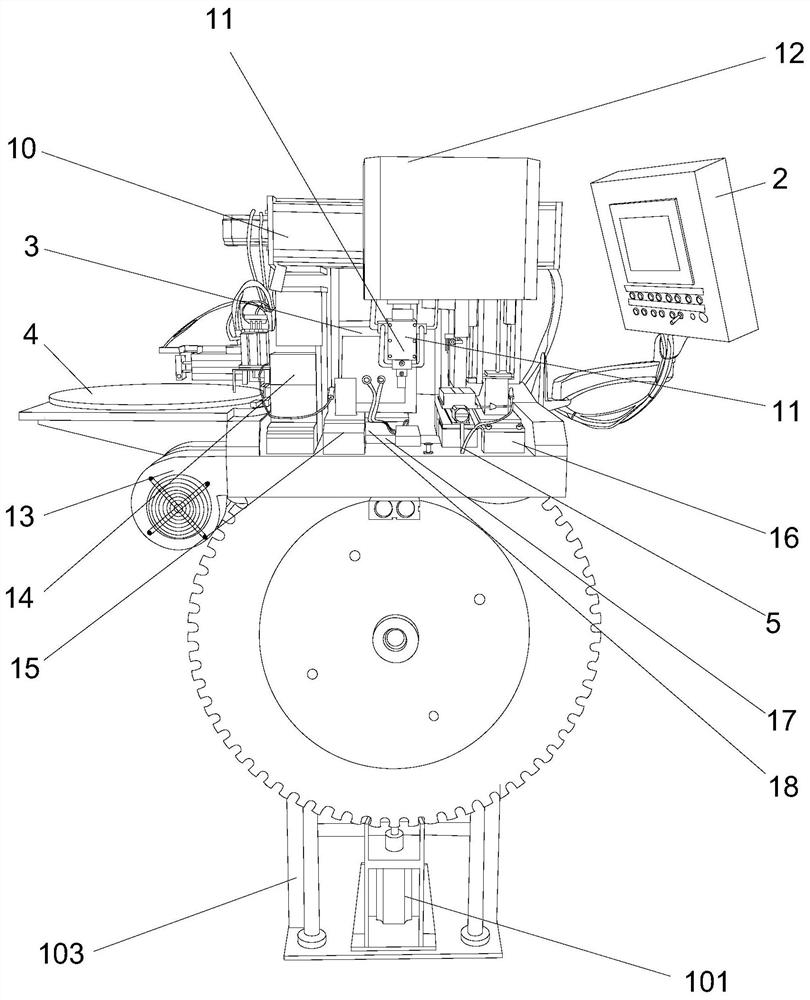

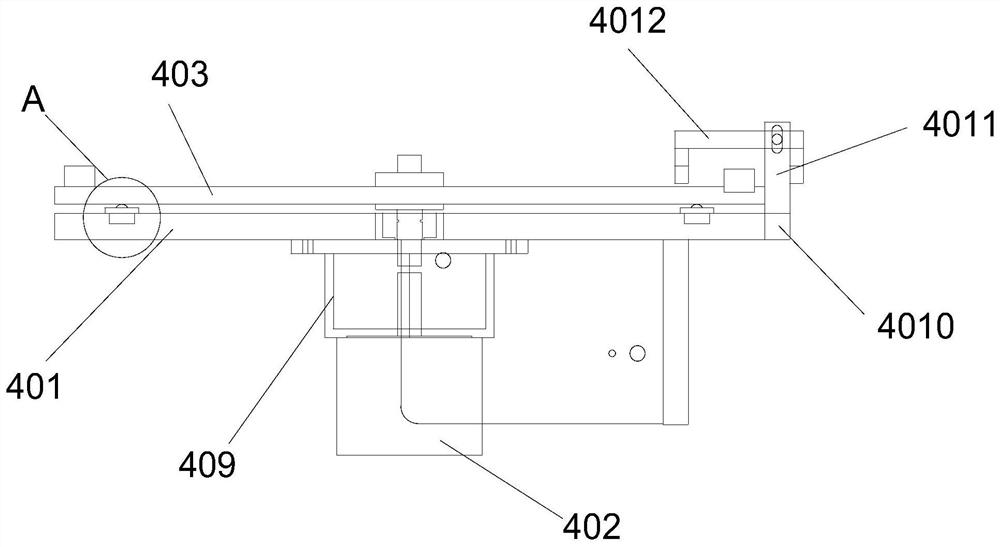

[0059] see Figure 1-Figure 18 , a kind of diamond automatic welding stand of the present embodiment, it is characterized in that, comprises frame 1, PLC controller 2, heater 3, cutter head rotary conveying module 4, cutter head positioning module 14, cutter head glue brushing module 15. Cutter Head Module 11, Cutter Head Lifting Module 12, Weld Sheet Conveying Module 5, Chip Bottom Brushing Module 16, Cutter Plate Thickness Measuring Module 17, B-axis Rotation Module 18, Moving Module 10 . Described frame 1 comprises workbench 102, support frame 103 and lifting device 101, and described workbench 102 is fixedly installed on the support frame 103, and described lifting device 101 is arranged on support frame 103, and is positioned at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com