Varnish baking heating lamp mounted in rail type

A heating lamp and track-type technology, which is applied to the device for coating liquid on the surface, pre-treatment surface, coating, etc., can solve the problems that cannot be folded and retracted, the swing arm and lifting arm are large, and occupy a large space. Achieve the effect of saving limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

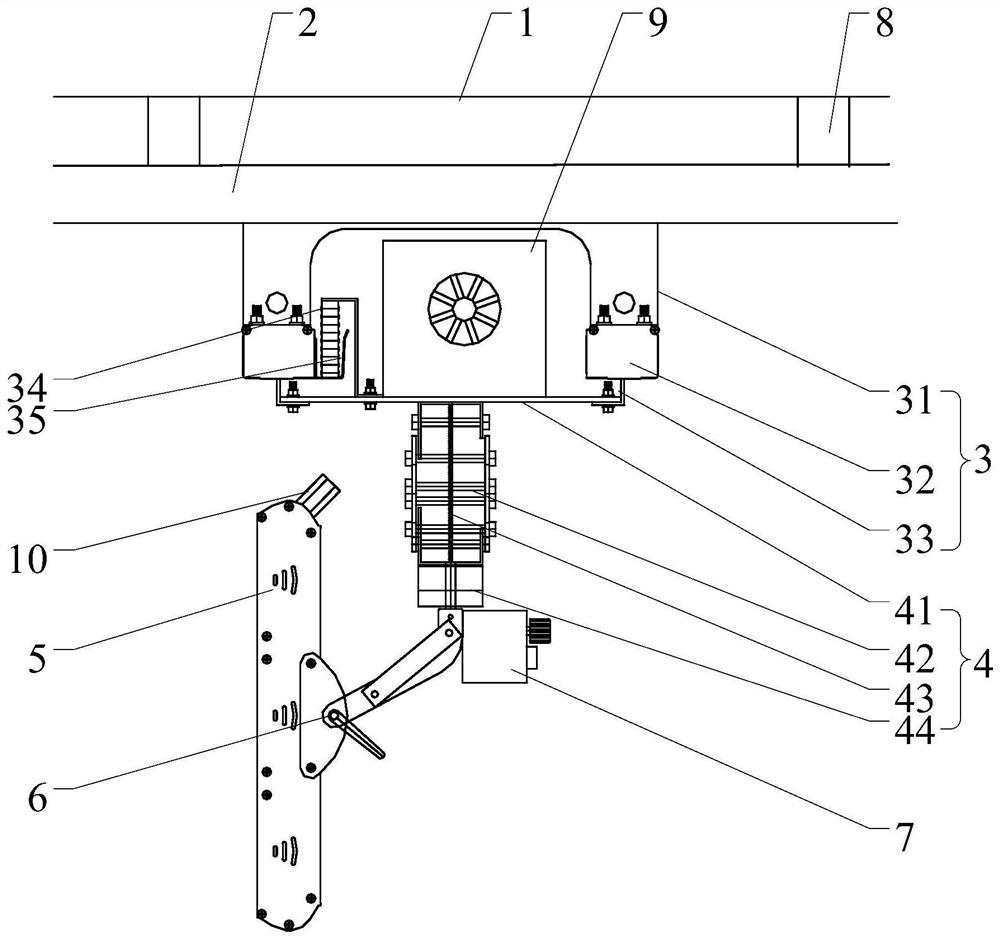

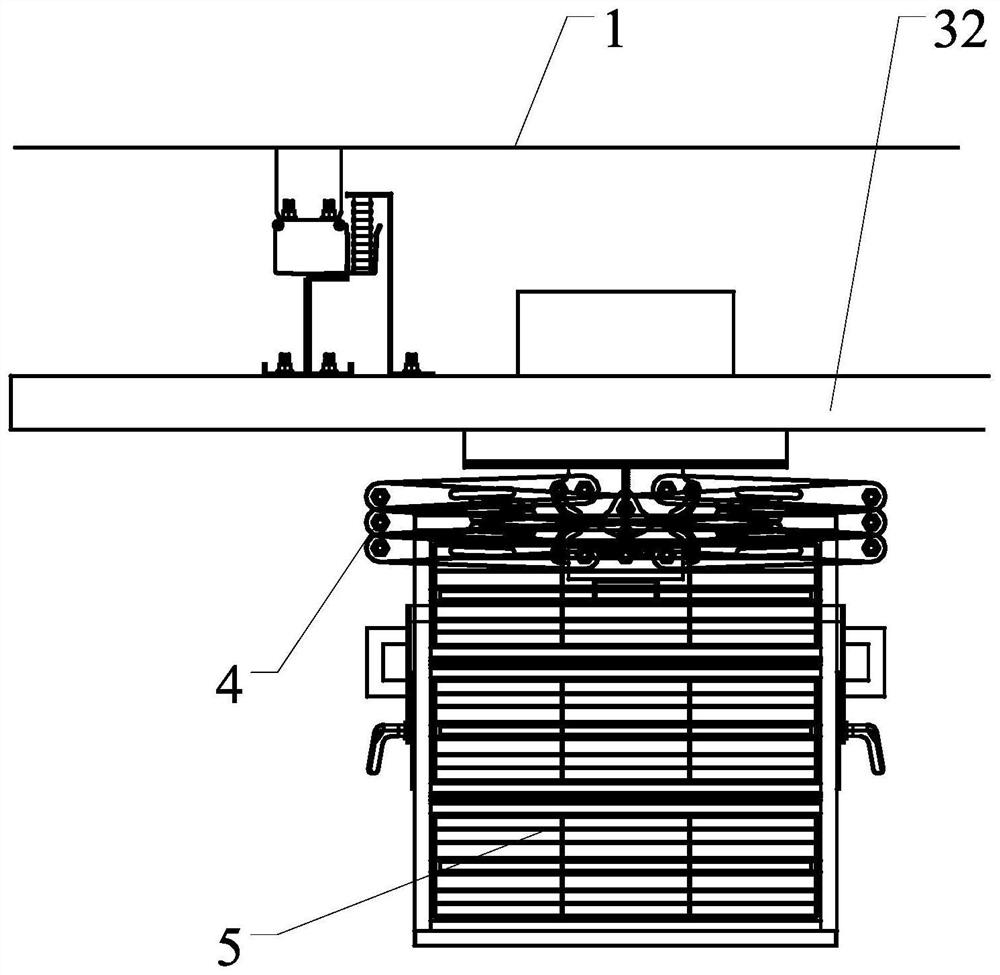

[0022] figure 1 It is a structural schematic diagram of an embodiment of a track-mounted paint heating lamp embodiment of the present invention, figure 2 It is a schematic diagram of the descending operation of the heating lamp box of an embodiment of a rail-mounted paint heating lamp embodiment of the present invention, image 3 It is a schematic diagram of the rising work of the heating lamp box of an embodiment of a rail-mounted paint heating lamp embodiment of the present invention, Figure 4 It is a schematic diagram of folding the heating lamp box of an embodiment of a track-mounted paint heating lamp according to the present invention. As shown in the figure, the present invention provides a rail-mounted paint heating lamp, which includes a longitudinal rail 2 connected to the room body 1, a lateral movement mechanism 3 connected to the longitudinal rail 2, and a lifting mechanism connected to the lateral movement mechanism 3 4 and the heating light box 5 connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com