Ultrasonic vibration filter screen spray waste gas treatment tower

A waste gas treatment tower, ultrasonic technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of low waste gas treatment efficiency, large water consumption, and inability to be widely promoted and applied, so as to improve the decomposition and treatment capacity. , Effective treatment, exhaust gas decomposition and the effect of strong treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

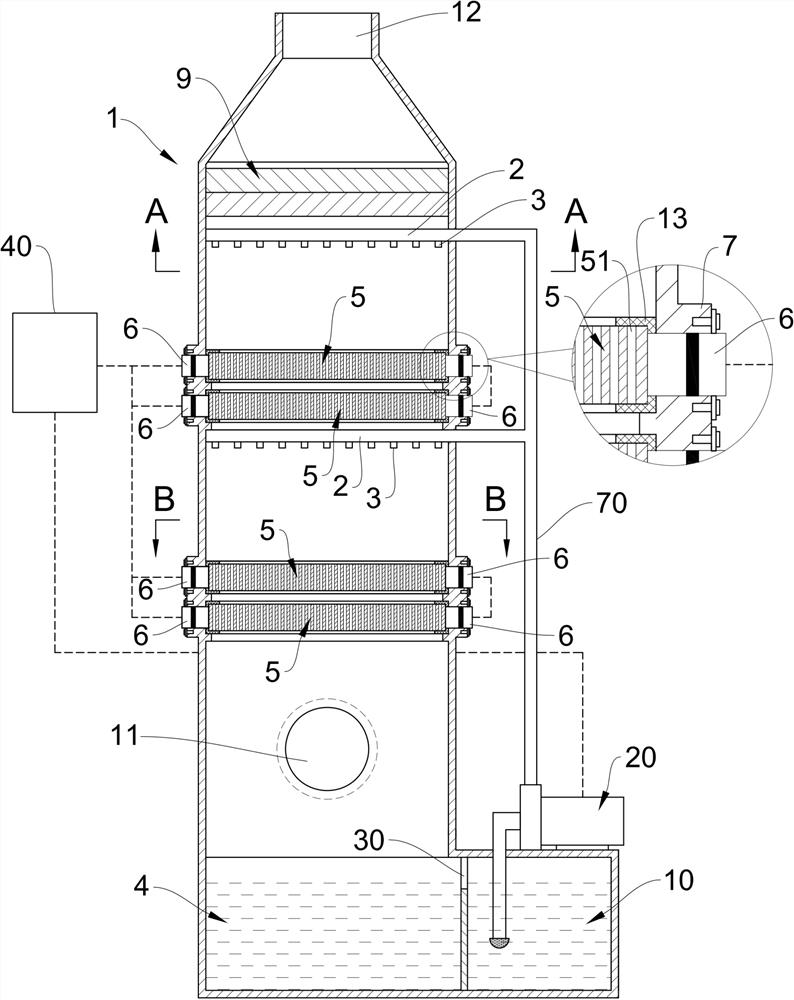

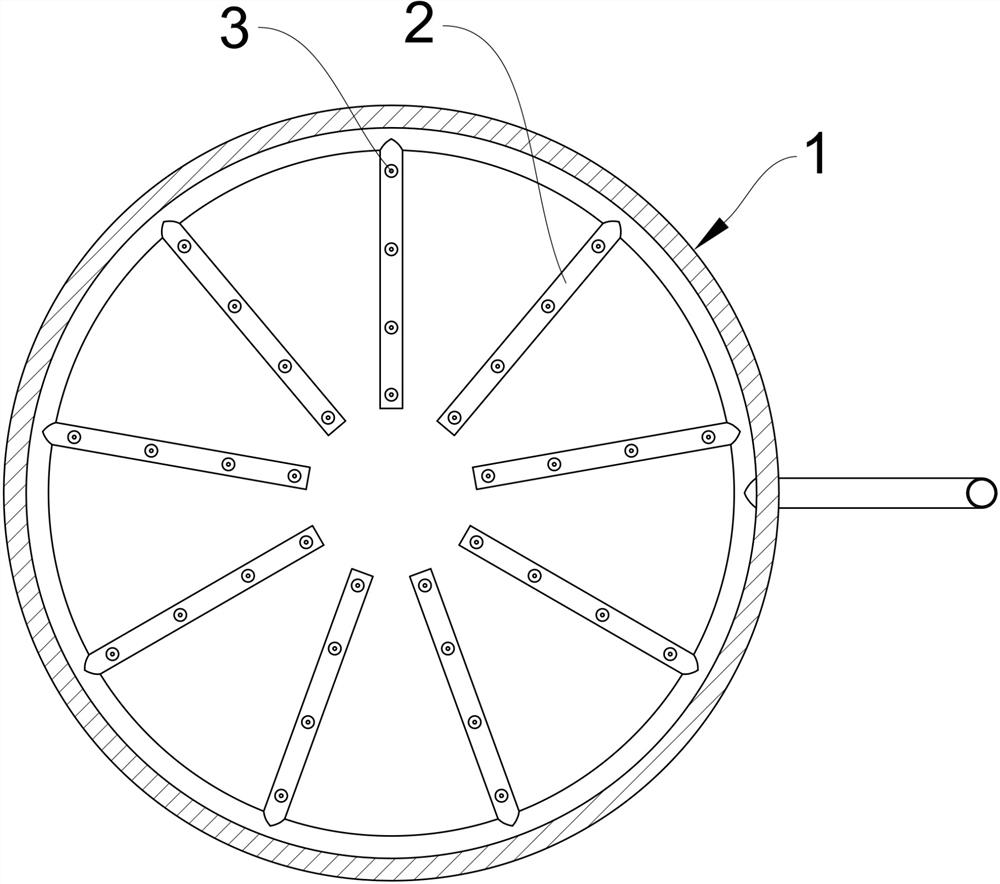

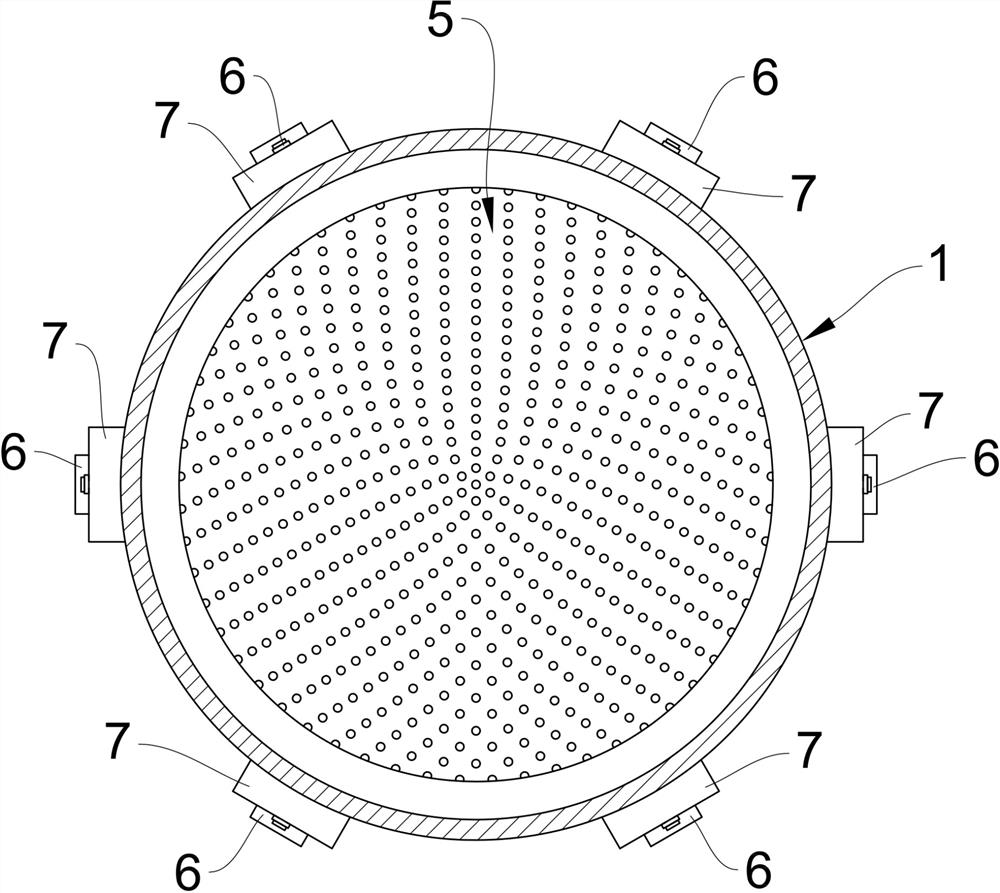

[0015] Such as figure 1 or Figure 4 As shown, an ultrasonic vibrating filter screen spray waste gas treatment tower according to the present invention includes a tower body 1 with an air inlet 11 and an air outlet 12, a spray pipe 2, a spray nozzle 3, and a water receiving and slag storage tank 4 and other components. In order to realize the proposed purpose of the present invention, and as figure 1 or Figure 4 As shown, the present invention also includes two key components such as a metal filter screen 5 and an ultrasonic transducer 6 . Wherein, a plurality of mesh holes 51 are evenly opened on the metal filter screen 5 , and the diameter of the mesh holes is 3mm-15mm, so as to ensure the effect of intercepting dust and impurities in the exhaust gas. another example figure 1 or Figure 4 As shown, the metal filter screen 5 is arranged transversely in the inner cavity of the tower body 1 so that it can intercept the inner cavity of the tower body 1 . The ultrasonic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com