Cigarette smoke cooling particles as well as preparation method and application thereof

A technology of cigarette smoke and particles, applied in the field of cigarette smoke cooling particles and its preparation, to avoid negative effects, improve heat conduction capacity, and enhance heat absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

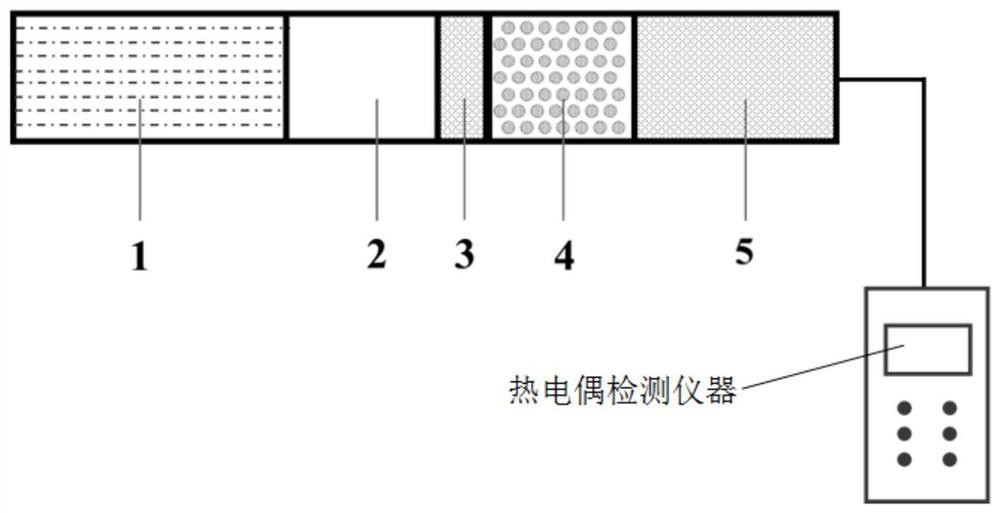

[0038] Weigh 20g of n-octadecane after melting, disperse with 20g of polyvinylpyrrolidone, 1g of cetearyl polyglucoside and 0.5g of polysorbate-80 in 100g of water, ultrasonicate for 3 hours to form a stable emulsion, add 2g of activated carbon to disperse evenly Finally, add 100mL of 17% sodium sulfate aqueous solution at a rate of 20mL / min, obtain a solid after sedimentation, filtration, and drying, and pulverize into particles of about 30 meshes to obtain the cooling particles. From its DSC curve ( figure 1 ) shows that the phase transition temperature of the cooling particles is 61.6°C, and the phase transition enthalpy is 108 J / g. Weigh 100 mg / piece of cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. see figure 2 , the cigarette sample includes a tobacco segment 1, a hollow filter rod segment 2, a first cellulose acetate filter rod segment 3, a cooling segment 4 and a secon...

Embodiment 2

[0040]Weigh 20g of cetyl alcohol and disperse it with 40g of polyvinylpyrrolidone and 1g of cetyl polyglucoside after melting in 200g of water / ethanol binary solution (the mass ratio of water to ethanol is 1:1). Stir at a speed of 3000 rpm for 12 hours to form a stable emulsion, add 0.5g of expanded graphite to disperse evenly, then add 200mL of a 15% magnesium sulfate aqueous solution at a rate of 10mL / min, and obtain a solid after deposition, filtration, and drying , crushed into particles of about 30 meshes to obtain the cooling particles. Weigh 50 mg / piece of cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. The structure of the cigarette sample in this example is the same as that in Example 1, the only difference is that the cigarette smoke cooling particles provided in this example are added in the cooling section, and the added amount is 50 mg / cigarette.

Embodiment 3

[0042] Weigh 20g of octadecanoic acid and disperse with 10g of polyvinylpyrrolidone, 2g of polysorbate-80 and 0.5g of cetyl glucoside after melting in 100g of water / ethanol binary solution (the mass ratio of water to ethanol is 1:4) , Ultrasound 4 hours to form a stable emulsion, add 0.2g carbon nanotubes to disperse evenly, then add 100mL ammonium sulfate aqueous solution with a concentration of 12% at a rate of 15mL / min, obtain a solid after deposition, filtration, and drying, and crush it into 30 The particles of about mesh are obtained to obtain the cooling particles. Weigh 80 mg / piece of cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. The structure of the cigarette sample in this example is the same as the cigarette sample in Example 1, the only difference is that the cigarette smoke cooling particles provided in this example are added in the cooling section, and the addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com