Process for recycling waste lithium batteries

A waste lithium battery and process technology, applied in the direction of secondary battery, battery recycling, recycling technology, etc., can solve the problems that the recycling process is difficult to realize industrialization, generate a large amount of waste gas or waste liquid, and the recycling cost is high, and achieve industrial application. High prospects, the effect of recycling and reuse, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

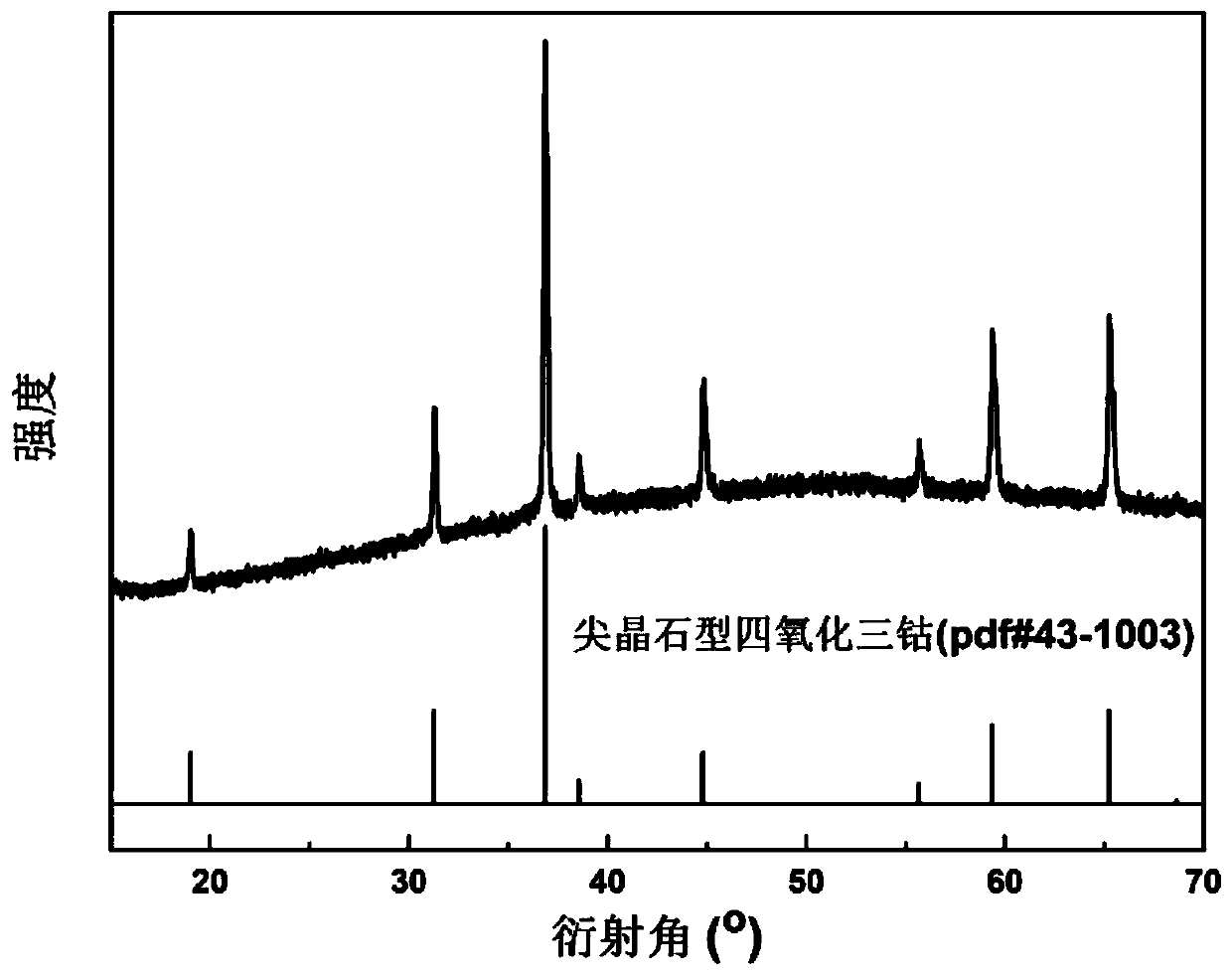

Image

Examples

Embodiment 1

[0030] This embodiment provides a process for recycling waste lithium batteries, comprising the following steps:

[0031] Prepare the deep eutectic solvent: mix and heat the quaternary ammonium salt and the amine compound to obtain the deep eutectic solvent, and the quaternary ammonium salt is selected from one or more of choline chloride, choline acetate or acetylcholine Mixing, the amine compound is selected from one or more mixing of urea, ethanolamine, triethanolamine;

[0032] Leaching: using the deep eutectic solvent to leach the positive electrode sheet disassembled from the waste lithium battery to obtain a metal-containing solution and an aluminum foil current collector.

[0033] In this embodiment, the high-value metals in the positive electrode sheets dismantled from waste lithium batteries can be recovered and reused by leaching with a deep eutectic solvent. It should be noted that the waste lithium battery in this embodiment refers to a lithium battery in which t...

Embodiment 2

[0035] This embodiment provides a process for recycling waste ternary lithium batteries. The waste ternary lithium batteries are nickel-cobalt lithium manganese oxide batteries. The process includes the following steps:

[0036] Battery pretreatment: Disassemble the waste ternary lithium battery to obtain the positive electrode sheet, clean and dry the positive electrode sheet, and then coarsely crush the positive electrode sheet to 80 mesh;

[0037]Prepare the deep eutectic solvent: mix and heat choline chloride and urea according to the molar ratio of 1:1, the heating temperature is 90°C, and the heating time is 5-8 hours to obtain the deep eutectic solvent;

[0038] Leaching: use the above-mentioned prepared deep eutectic solvent to leach the positive electrode sheet of the ternary battery that has been pretreated by the battery to obtain a metal-containing solution and an aluminum foil current collector; where the mass of the positive electrode sheet of the ternary battery ...

Embodiment 3

[0046] This embodiment provides a process for recycling waste ternary lithium batteries. The waste ternary lithium batteries are nickel-cobalt lithium manganese oxide batteries. The process includes the following steps:

[0047] Battery pretreatment: disassemble the waste ternary lithium battery to obtain the positive electrode sheet, clean and dry the positive electrode sheet, and then coarsely crush the positive electrode sheet to 120 mesh;

[0048] Prepare the deep eutectic solvent: mix and heat choline chloride and urea according to the molar ratio of 1:2, the heating temperature is 93°C, and the heating time is 6-8 hours to obtain the deep eutectic solvent;

[0049] Leaching: use the above-mentioned prepared deep eutectic solvent to leach the positive electrode sheet of the ternary battery that has been pretreated by the battery to obtain a metal-containing solution and an aluminum foil current collector; where the mass of the positive electrode sheet of the ternary batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com