Preparation process of high-voltage anode foil for contracted ox horn type aluminum electrolytic capacitor

An aluminum electrolytic capacitor and its preparation technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of large leakage current, low anode foil capacity, and poor mechanical strength, and achieve easy control, high electrostatic capacity, and excellent surface performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

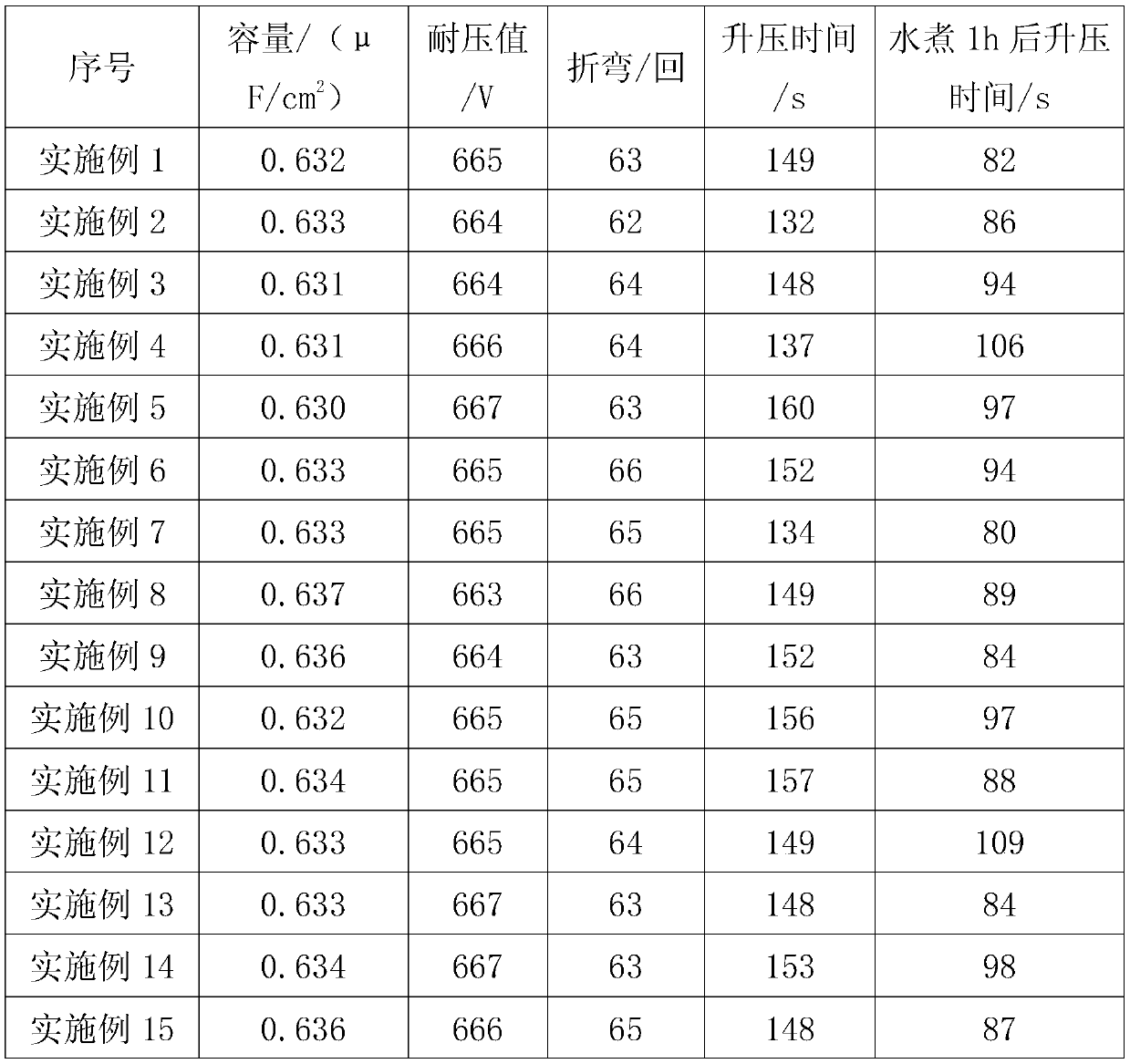

Embodiment 1

[0088] The specific operation steps are as follows:

[0089] (1) Primary feed: the conductive silver roller supplies power to the primary and secondary forming feeds.

[0090] (2) Boiling in high temperature water: Soak the foil in water above 97°C for 12 minutes.

[0091] (3) One-stage chemical conversion: use a forming solution containing 1 g / L ammonium dihydrogen phosphate, 0.5 g / L citric acid, and 0.5 g / L triammonium citrate to perform primary chemical conversion. Current density 80mA / cm 2 , the voltage is 170V, the formation time is 9min, and the processing temperature is 90°C.

[0092] (4) Secondary chemical conversion: perform secondary chemical conversion with a forming solution containing 0.5 g / L ammonium dihydrogen phosphate, 0.7 g / L citric acid and 0.7 g / L triammonium citrate. Current density 80mA / cm 2 , the voltage is 340V, the formation time is 9min, and the processing temperature is 90°C.

[0093] (5) Tertiary chemical conversion: use a forming solution cont...

Embodiment 2

[0108] Embodiment 2: The preparation process is the same as in Embodiment 1, the difference is that the first stage forming liquid:

[0109] Primary chemical conversion: use a forming solution containing 2 g / L ammonium dihydrogen phosphate, 0.5 g / L citric acid and 0.5 g / L triammonium citrate to perform primary chemical conversion. Current density 80mA / cm 2 , the voltage is 170V, the formation time is 9min, and the processing temperature is 90°C.

[0110] Under the condition of anodizing at 670V voltage, the foil capacity is 0.633μF / cm 2 , the withstand voltage value is 664V, the bending time is 62 times, and the boost time after 1h boiling is 86s.

Embodiment 3

[0111] Embodiment 3: The preparation process is the same as in Embodiment 1, the difference is that the first stage forming liquid:

[0112] Primary chemical formation: use a forming solution containing 3g / L ammonium dihydrogen phosphate, 0.5g / L citric acid and 0.5g / L triammonium citrate for primary chemical formation, with a current density of 80mA / cm 2 , the voltage is 170V, the formation time is 9min, and the processing temperature is 90°C.

[0113] Under the condition of anodizing at 670V voltage, the foil capacity is 0.631μF / cm 2 , the withstand voltage value is 664V, the bending time is 64 times, and the boost time after 1h boiling is 94s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com