Rolling bearing performance degradation evaluation method based on HWPSO-SVDD model

A technology of HWPSO-SVDD and rolling bearings, applied in computational models, biological models, geometric CAD, etc., can solve problems such as inaccurate model prediction results and local optimum

Active Publication Date: 2020-08-28

SHANGHAI UNIV OF ENG SCI

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the parameter optimization of the current SVDD model is prone to fall into the defect of local optimum, or the prediction result of the model is inaccurate due to the blindness of artificial selection of model parameters.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0210] In this embodiment, the test data from the Intelligent Maintenance Center of the University of Cincinnati in the United States is used for the test. The test platform is as follows: Figure 4 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch circle diameter | aaaaa | aaaaa |

Login to View More

Abstract

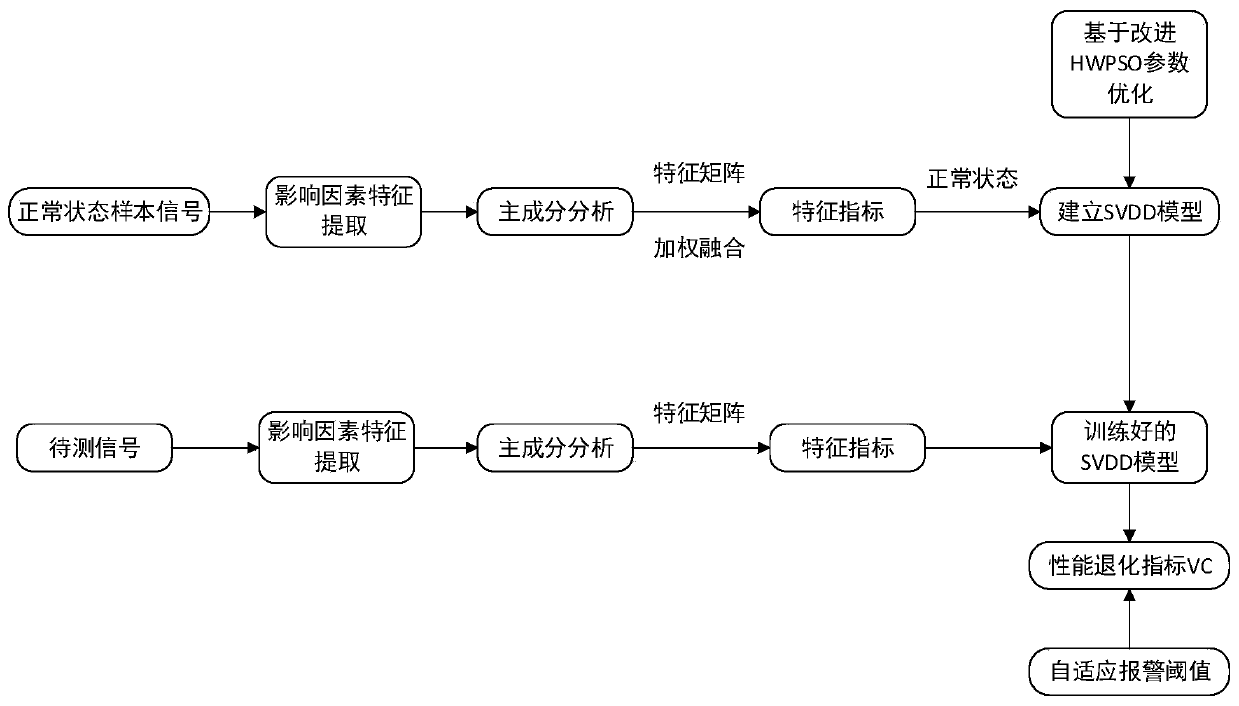

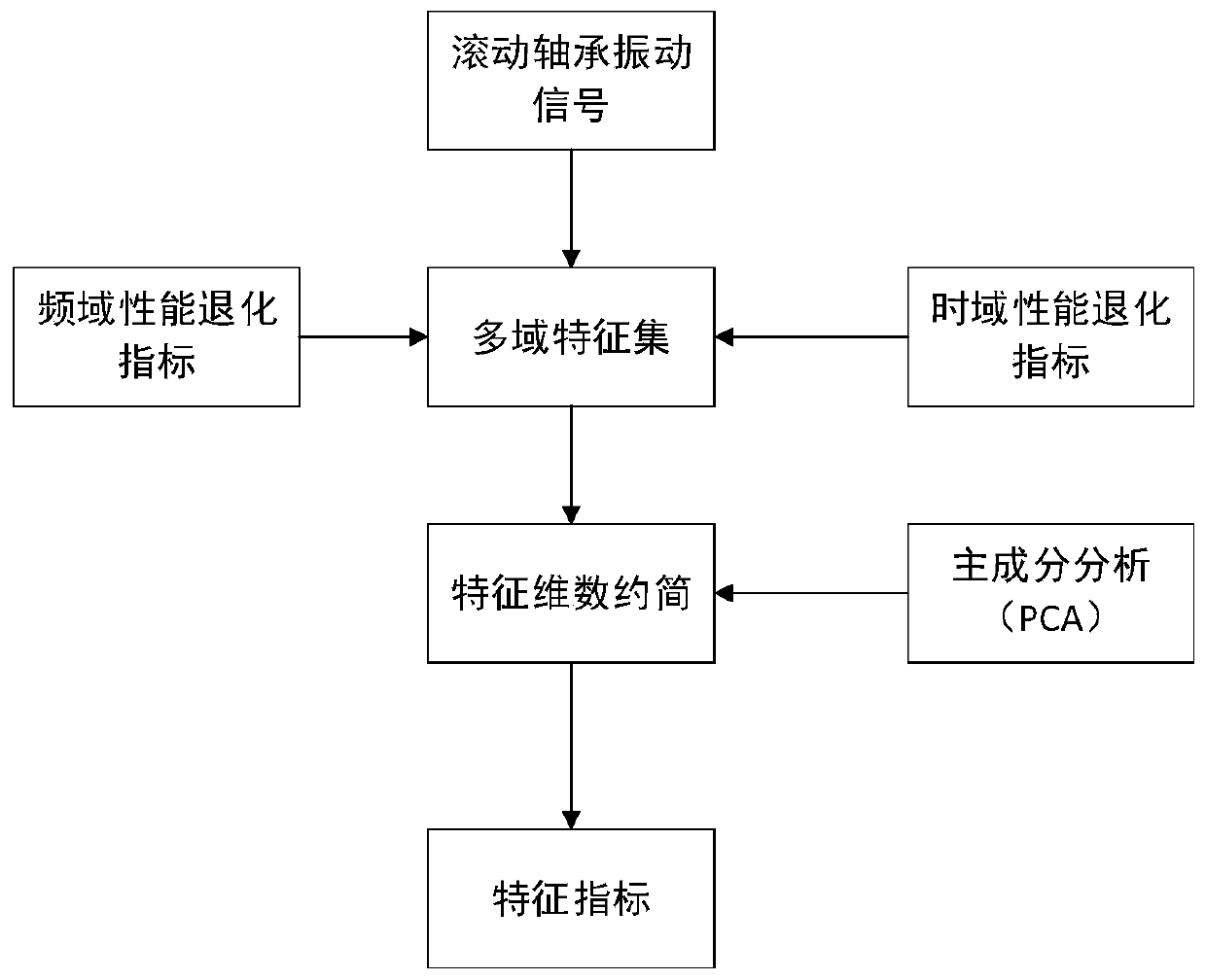

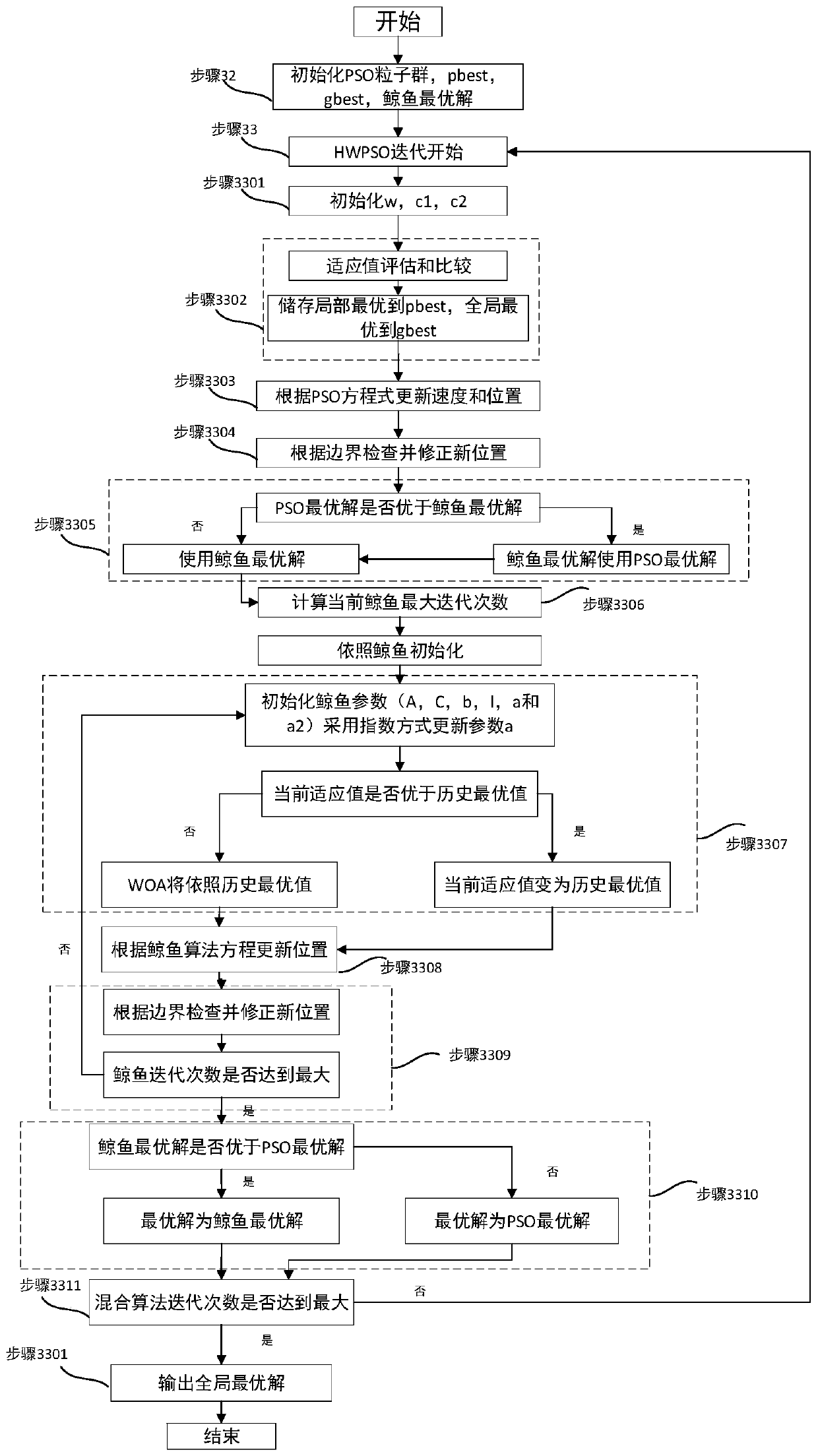

The invention relates to a rolling bearing performance degradation evaluation method based on an HWPSO-SVDD model, and the method comprises the following steps: S1, obtaining a feature index of a normal rolling bearing vibration signal, obtaining a fusion feature index through a PCA algorithm, and building a training sample; S2, optimizing a penalty parameter C and a nuclear parameter delta of theSVDD model by utilizing an HWPSO optimization algorithm; S3, constructing an HWPSO-SVDD model by using the penalty parameter C and the kernel parameter delta obtained by optimization; S4, inputting the training sample into an HWPSO-SVDD model for model training to obtain a trained performance degradation evaluation model; S5, acquiring a fusion characteristic index of the vibration signal of therolling bearing to be tested, and calculating to obtain a performance degradation index Vc value of the rolling bearing to be tested by using the trained performance degradation evaluation model; andS6, setting a self-adaptive alarm threshold, and when the Vc value exceeds the self-adaptive alarm threshold, carrying out early warning on the early degradation state of the bearing, so that the method has the advantages of improving prediction accuracy and robustness and the like.

Description

technical field [0001] The invention relates to the field of rolling bearing performance evaluation, in particular to a rolling bearing performance degradation evaluation method based on the HWPSO-SVDD model. Background technique [0002] Mechanical equipment is used in all aspects of human life, work and production, and plays a pivotal role in it. At present, machinery and equipment are developing towards large-scale, high-speed, precision, systematization, continuity and automation. The operating environment of machinery and equipment is becoming more and more complex and changeable, which poses new challenges for the health management of equipment. . With the operation of equipment, problems such as aging of parts, reduced reliability, and reduced remaining life gradually appear. Whether the equipment can continue to work safely and efficiently, and whether maintenance can be performed in a timely and effective manner, urgently needs to be resolved by humans. Once the e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/17G06F30/20G06K9/62G06N3/00G01M13/045G06F119/04

CPCG06F30/17G06F30/20G06N3/006G01M13/045G06F2119/04G06F18/2135G06F18/253Y02T90/00

Inventor 廖爱华吴义岚丁亚琦周炯余佑民

Owner SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com