Flue gas treatment recycling system and recycling method thereof

A technology of recycling and flue gas treatment, applied in gas treatment, combustion methods, separation methods, etc., can solve the problems of cold source equipment freezing, waste of water resources, failure to use normally, etc., to increase temperature, increase air temperature, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

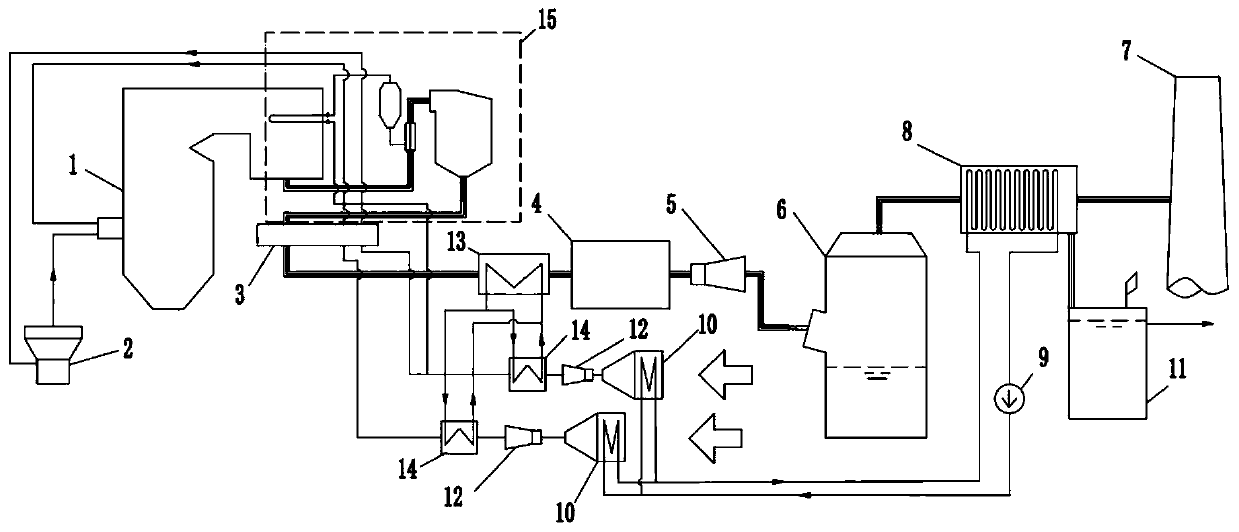

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0039] Such as Figure 1 to Figure 3 As shown, a flue gas treatment recycling system includes a boiler 1, a desulfurization tower 6, a purification condenser 8 and a fresh air cooler 10;

[0040] The air inlet of the boiler 1 is connected to the blower 12, and the flue gas outlet of the boiler 1 is connected to the inlet of the desulfurization tower 6;

[0041] The flue gas side inlet of the purification condenser 8 is connected with the outlet of the desulfurization tower 6 through a pipeline, and the flue gas side outlet of the purification condenser 8 is connected with the chimney 7 through a pipeline; The condensed water storage tank 11 is connected;

[0042] The refrigerant side outlet of the fresh air cooler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com