Large filling type karst cave geological tunnel foundation reinforcing structure and construction method thereof

A technology of foundation reinforcement and construction method, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of time-consuming and labor-intensive production process, difficulty in lowering steel cages, large length-to-diameter ratio, etc., so as to avoid material consumption and waste. , Prevent frequent collapse and buried holes, good filling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

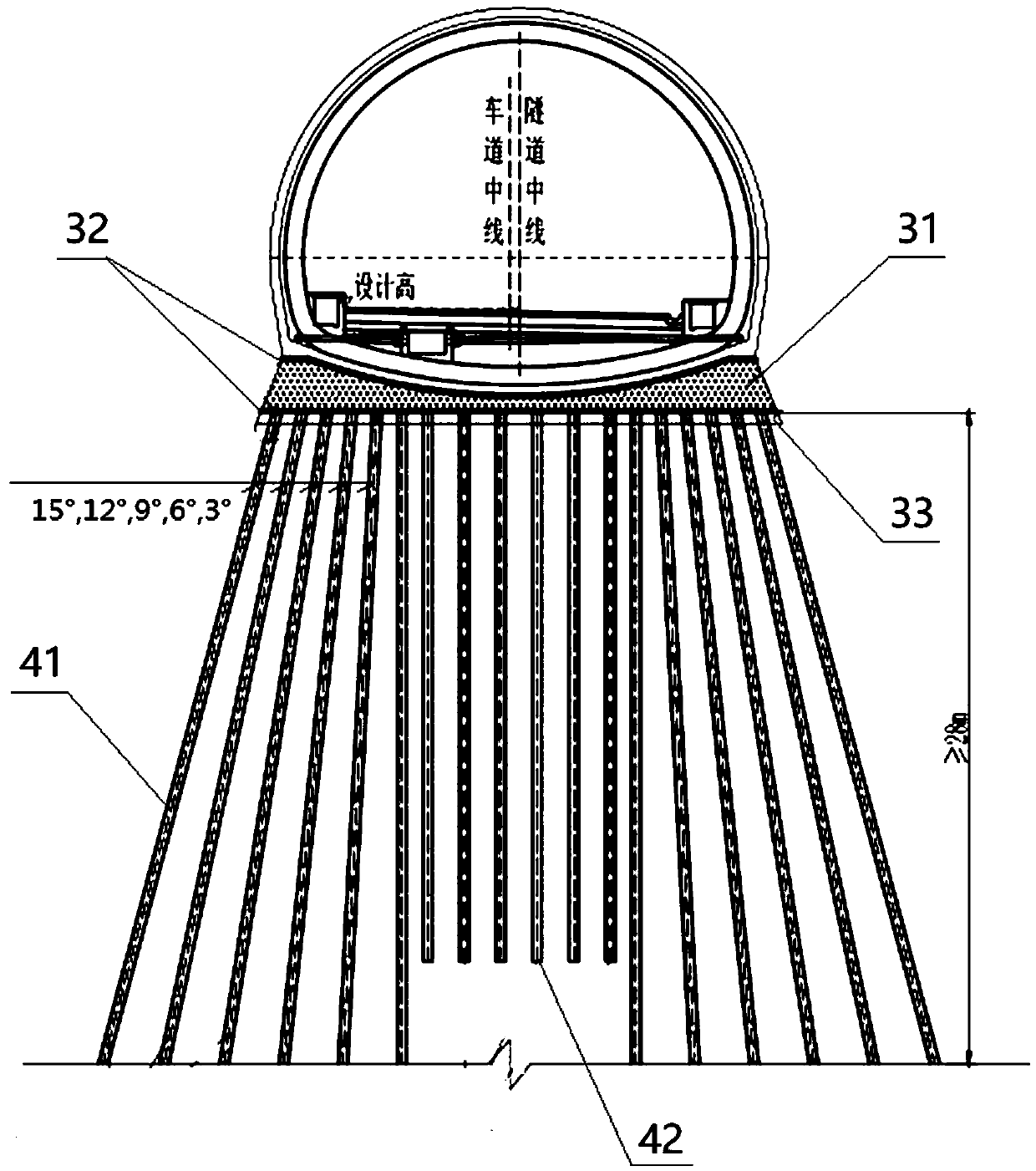

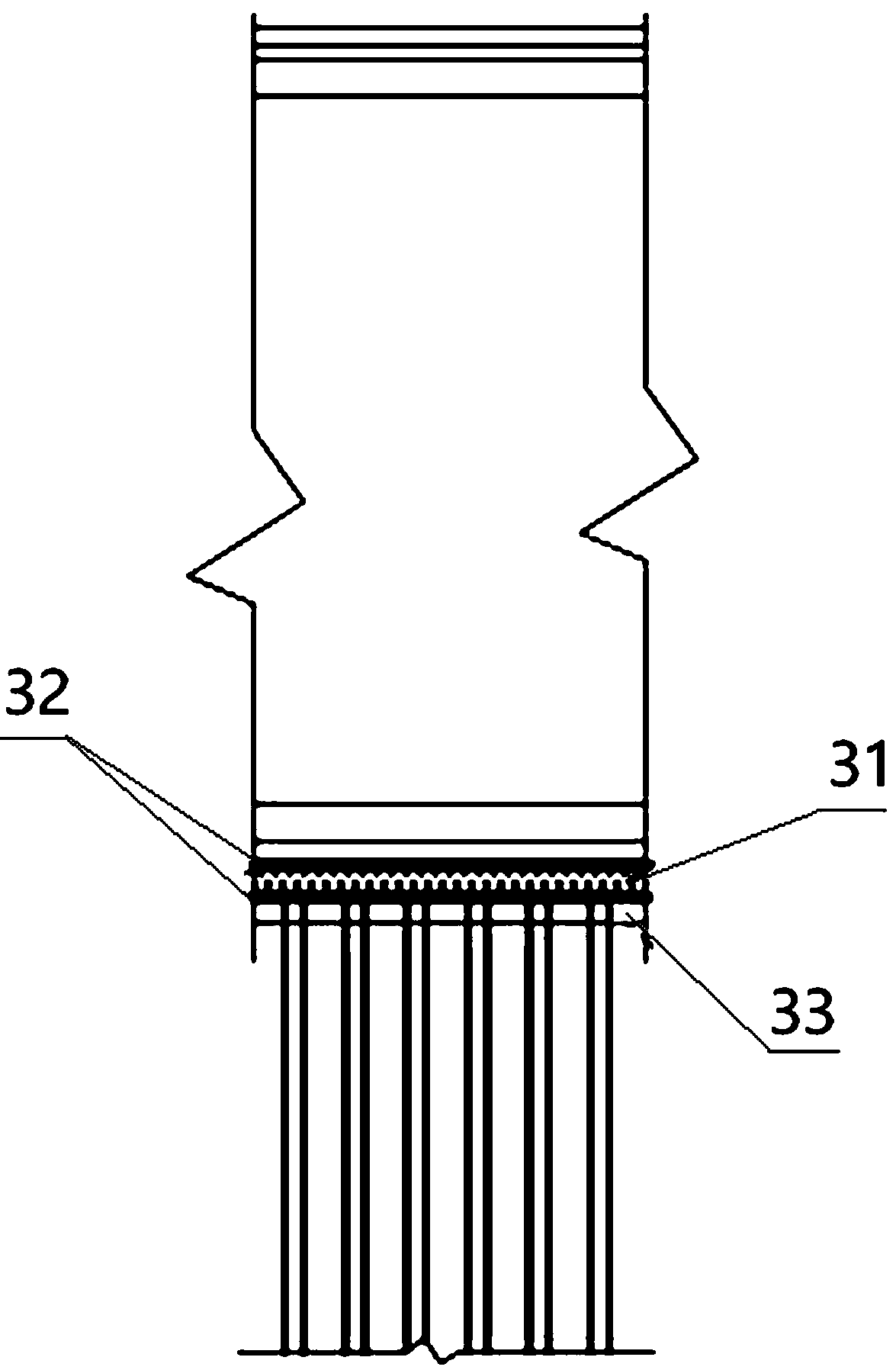

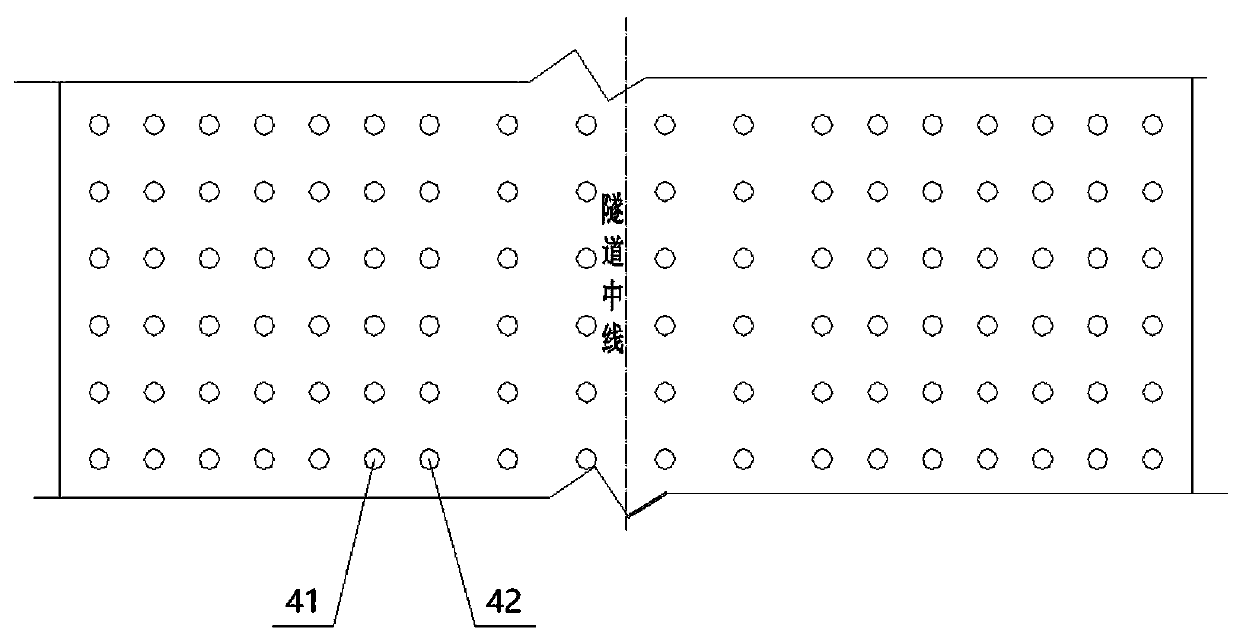

[0042] For the foundation reinforcement structure of large-scale filled karst cave geological tunnels, multiple rows of grouted steel pipe piles are arranged at the bottom of the tunnel inversion along the length of the tunnel to penetrate into the underground bedrock or into the soil at a certain depth, and graded steel pipe piles are laid on the top of the steel pipe piles at the bottom of the tunnel. For the crushed stone layer, concrete caps shall be poured and laid above the graded crushed stone layer.

[0043] For the multiple rows of grouted steel pipe piles, several rows of grouted steel pipe piles in the middle are vertically downward, and several rows of grouted steel pipe piles on the left and right sides of the center line of the tunnel are inclined downward on both sides.

[0044] For the grouted steel pipe piles on the left and right sides of the center line of the tunnel, the inclination angles of the steel pipe piles in two adjacent rows are 3° larger on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com