Yarn dyeing machine

A technology of yarn dyeing machine and dyeing cylinder, which is applied in the field of yarn dyeing machines, can solve the problems of uneven dyeing shade, easy entanglement of dyed matter, cumbersome procedures, etc., achieve enhanced stirring and dispersing effect, increase dyeing liquid space, turn over Stir the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

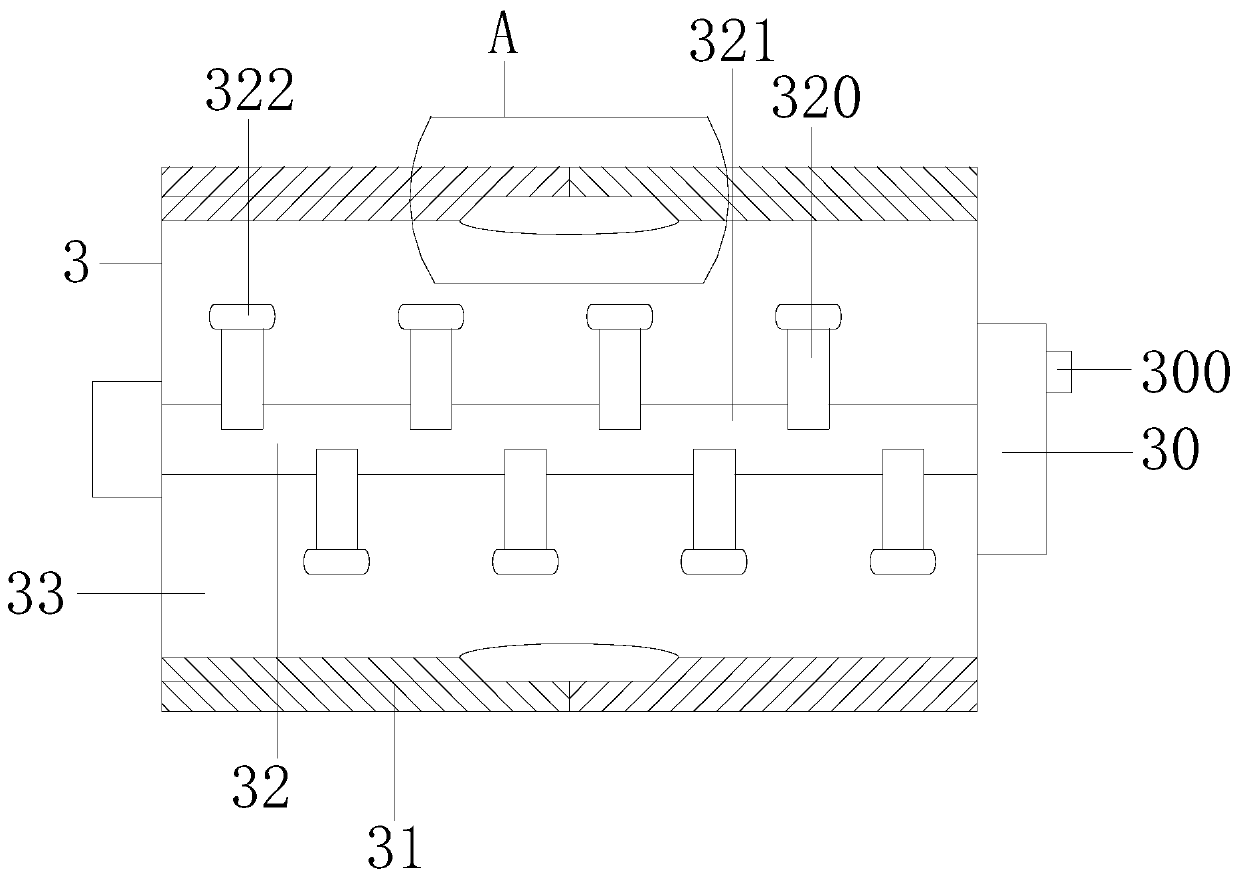

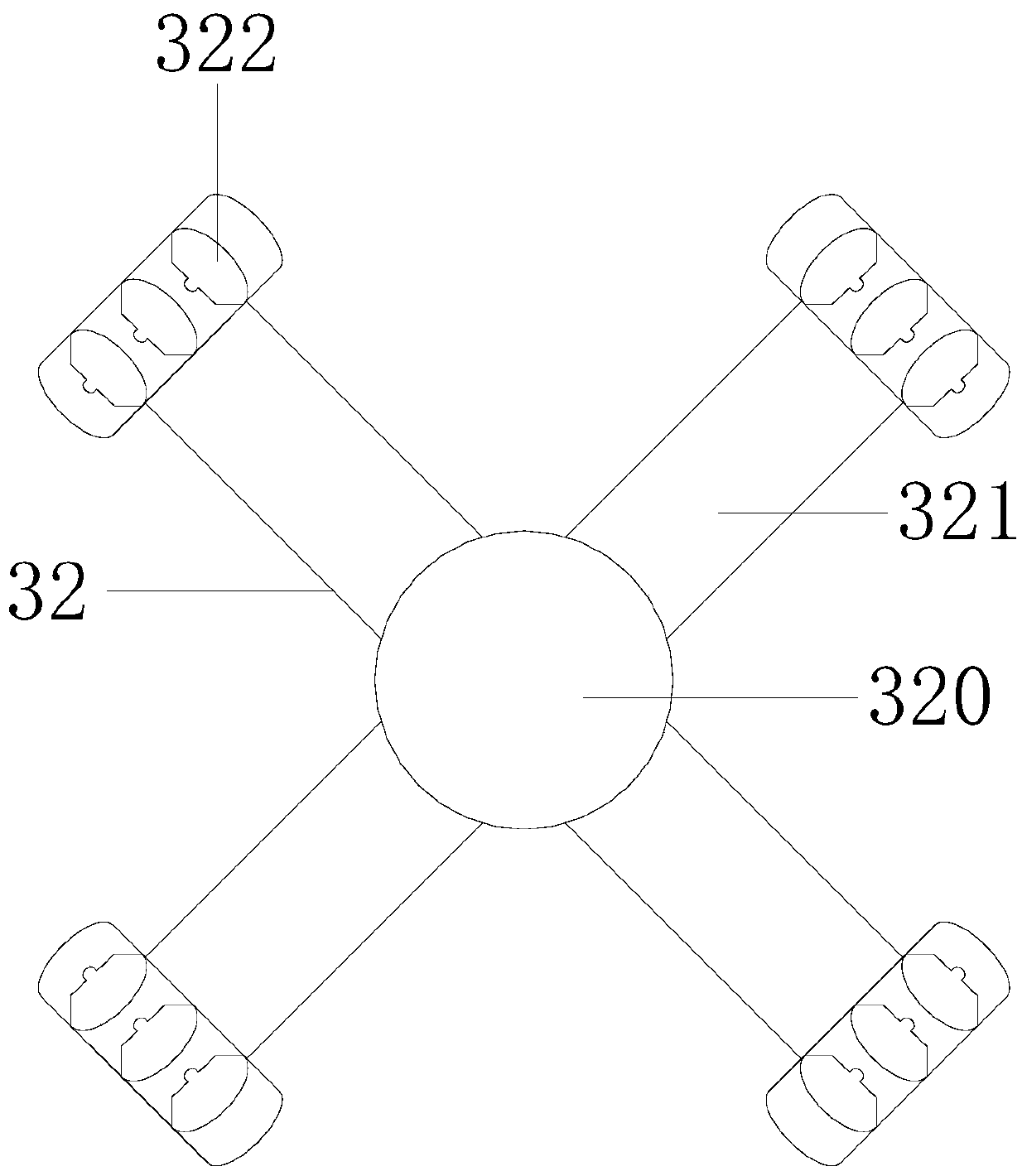

[0027] Example 1 please refer to Figure 1-5 The present invention provides a technical solution for a yarn dyeing machine: its structure includes a liquid tube 1, a dye drum frame 2, a dye drum 3, and a motor 4. The liquid tube 1 is fitted with the rear end of the dye drum frame 2, so The dyeing drum 3 is attached to the front end of the liquid pipe 1 and the inside of the dyeing drum machine frame 2. The left end of the motor 4 is installed and connected with the dyeing drum machine frame 2 and the dyeing drum 3, and the right end of the dyeing drum machine frame 2 is equipped with a control button. 20. The dyeing drum 3 is composed of a detachable rotating machine 30, a toning device 31, a stirring rod 32, and a dyeing drum 33. The detachable rotating machine 30 drives the stirring rod 32 to stir the materials. The dye solution is soaked once, and the material is evenly dispersed during rotation, and the dyeing effect is increased in a large space. The detachable rotating mac...

Embodiment 2

[0029] Example 2 please refer to Figure 6-8 , The present invention provides a technical solution for a yarn dyeing machine: the structure of the toning device 31 includes an upper mounting rail frame 310, a lower mounting frame 311, and a toning structure 312, which are realized when the upper mounting rail frame 310 slides The opening and closing of the upper port of the toning structure 312 enables flexible transmission. The upper mounting rail frame 310 is connected to the upper rail of the lower mounting frame 311, and the lower mounting frame 311 is installed and connected to the left and right ends of the color matching structure 312. The color structure 312 includes a liquid spray arc frame 3120, a structural liquid outlet rod 3121, a structural welding frame 3122, a liquid extractor 3123, and a structural mounting frame 3124. The liquid extractor 3123 is used to detect the color of the liquid. The bottom of the rod 3121 is connected to the left and right ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com