Deacidification device for atomizing alkali liquor by using double-fluid spray gun

A dual-fluid spray gun and dual-fluid technology is applied in gas treatment, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high atomizer cost, large atomizer vibration, and high investment cost, and achieve equipment failure and Low maintenance cost, high deacidification efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

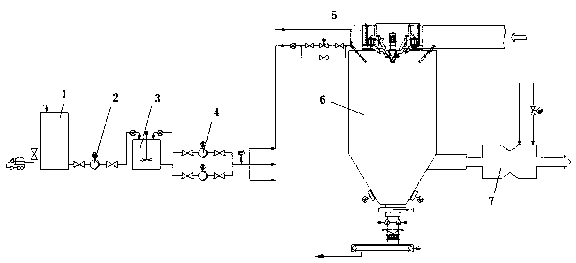

[0020] refer to figure 1 , a deacidification device utilizing a two-fluid spray gun to atomize lye, comprising a lye storage tank 1, a transfer pump 2, a stirring tank 3, a jet pump 4, a two-fluid atomization spray gun 5 and a deacidification reaction tower 6, the deacidification The lower part of one side of the reaction tower 6 is equipped with a dry mixing chamber 7, which can further process the acid gas, so that the acid gas treatment effect is higher.

[0021] The lower parts of both sides of the deacidification reaction tower 6 are equipped with vibrators, which can remove impurities from the wall of the deacidification reaction tower 6 and improve the perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com