Method for machining CAF-resistant circuit board through numerical control drilling machine based on CNC machining

A processing method and circuit board technology, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of easy errors, large randomness, and easy leakage, etc., so as to prolong the positioning time, reduce error factors, reduce The effect of drilling hole deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of CNC drilling machine CNC processing resistant CAF circuit board processing steps:

[0024] For dense hole drilling, first create test data for simulation operation, and the specific parameters are set as follows figure 1 , by setting the hole spacing (hole side to hole side) of 0.3mm (11.811mil) holes as the data of 6.0mil-17.0mil spacing;

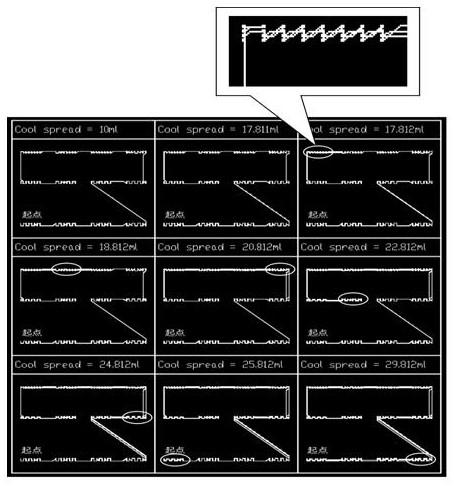

[0025] By increasing the output parameter Cool spread to realize the function of jumping drill, but the actual value of Cool spread is unknown, by constantly changing the set value of Cool spread to output different data, to simulate and observe the change of the spindle path of dense holes on the CNC drilling machine, simulate The process is as follows (below figure 2 The line drawn from the starting point is the movement path of the spindle on the CNC drilling machine);

[0026] Combined with the results of the simulation output, it can be known that in figure 2 Among them, when Cool spread = 17.812ml, that is, grea...

Embodiment 2

[0031] A kind of CNC drilling machine CNC processing resistant CAF circuit board processing steps:

[0032] For dense hole drilling, first make test (test) data for simulation operation, the specific parameters are set to 0.4mm (12.11) hole spacing (hole edge to hole edge) and 7.0mil spacing data;

[0033] By increasing the output parameter Cool spread to realize the function of jumping drill, but the actual value of Cool spread is unknown, by constantly changing the set value of Cool spread to output different data, to simulate and observe the change of the spindle path of dense holes on the CNC drilling machine, simulate Process such as figure 2 The line drawn from the starting point is the movement path of the spindle on the CNC drilling machine;

[0034] Combined with the results of the simulation output, it can be known that when Cool spread = 20.812ml, that is, greater than 19.11 (12.11+7), the moving path of the 7.0mil hole spacing has changed, and the Cool spread set...

Embodiment 3

[0039] A kind of CNC drilling machine CNC processing resistant CAF circuit board processing steps:

[0040] For dense hole drilling, first make test (test) data for simulation operation, and the specific parameters are set to the data that the hole spacing (hole side to hole side) of 0.5mm holes is 6.5mil spacing;

[0041] By increasing the output parameter Cool spread to realize the function of jumping drill, but the actual value of Cool spread is unknown, by constantly changing the set value of Cool spread to output different data, to simulate and observe the change of the spindle path of dense holes on the CNC drilling machine, simulate Process such as figure 2 The line drawn from the starting point is the movement path of the spindle on the CNC drilling machine;

[0042] Combined with the results of the simulation output, it can be known that when Cool spread = 18.812ml, that is, greater than 18.96.811 (12.31+6.5), the moving path of the 6.5mil hole spacing has changed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com